Chapter 2 BK730-2 Base Page 2-15

2.2.4.2 Auto/Manual Switch

The Auto/Manual switch enables the operator to bypass the speed control board and to

operate the machine as if the board were not installed. This enables a supervisor or

operator to quickly swap a Tabber between systems which have speed control and others

which do not. The Auto configuration will enable the speed control option whereas the

manual setting disables it. The switch is a toggle switch near the edge of the board.

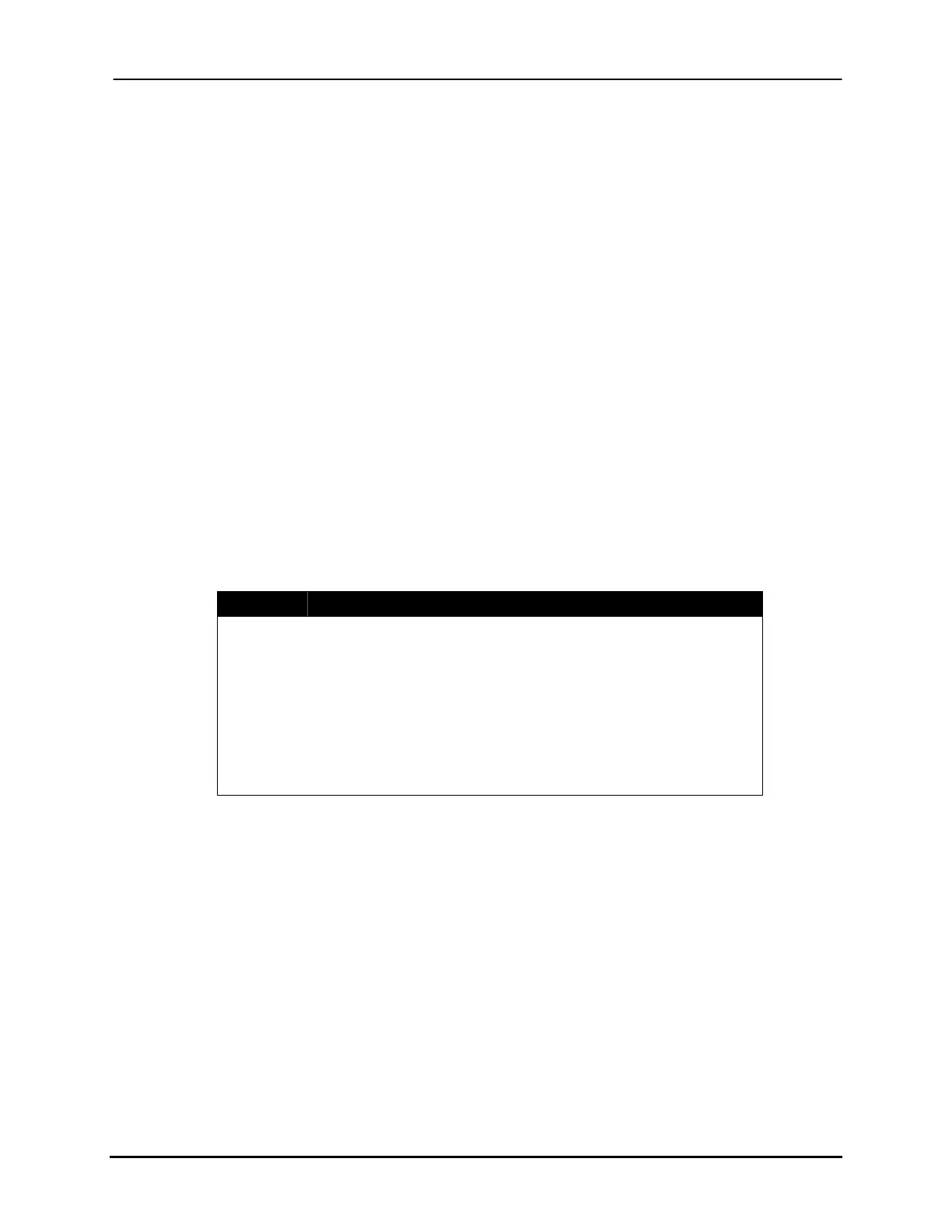

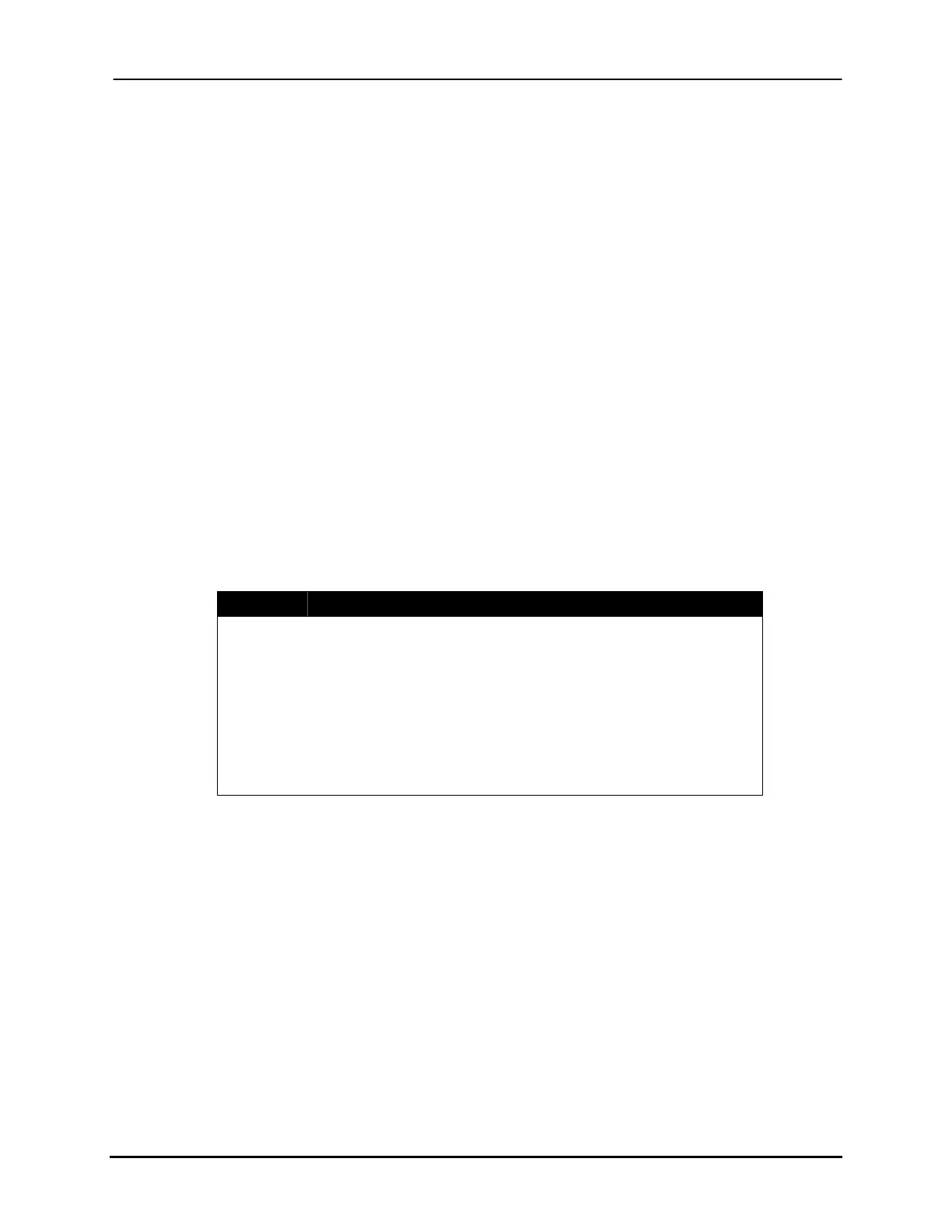

2.2.4.3 LED Assignments

The Speed Control Board has four yellow status LEDs and Table 2-5 defines what each

LED represents depending on whether they are ON or OFF. There is also one green status

LED, D1, used to indicate that power is being supplied to the board.

Table 2-5: Status LED indicator definitions.

LED Description

D1

Indicates 12 VDC is being supplied to the board when on

D8

Off if the speed reported by the encoder is less than 0.05 m/s

On if the speed reported by the encoder is greater than 0.05 m/s

D9

Off if the speed reported by the encoder is less than 1 m/s

On if the speed reported by the encoder is equal to 1 m/s

Blinks if the speed reported by the encoder is greater than 1 m/s

D10

On if Photo 1 is blocked

D11

On if Photo 2 is blocked

2.2.4.4 Speed Control Board Calibration

Before it can be used, the Speed Control Board must be calibrated to the base whose speed

it will be controlling. The following is a mandatory step-by-step calibration procedure to

be performed on every system requiring the speed control option. It is important to note

that only one of the DIP switches on S3 can be enabled during normal operation.

1. Switch the Speed Control Board Auto/Manual switch to Manual. Set the

Production Pot on the transport base to its minimum setting and start the transport

Buskro Ltd. BK730-2 Tabber

Loading...

Loading...