Chapter 2 BK730-2 Base Page 2-14

2.2.4.1 Dip Switch Settings

The Speed Control Board has two 8 position DIP switches used to configure its operating

mode based on the system’s setup requirements and position in the Production line. Table

2-3 and Table 2-4 list the switch assignments for DIP S2 and S3 respectively.

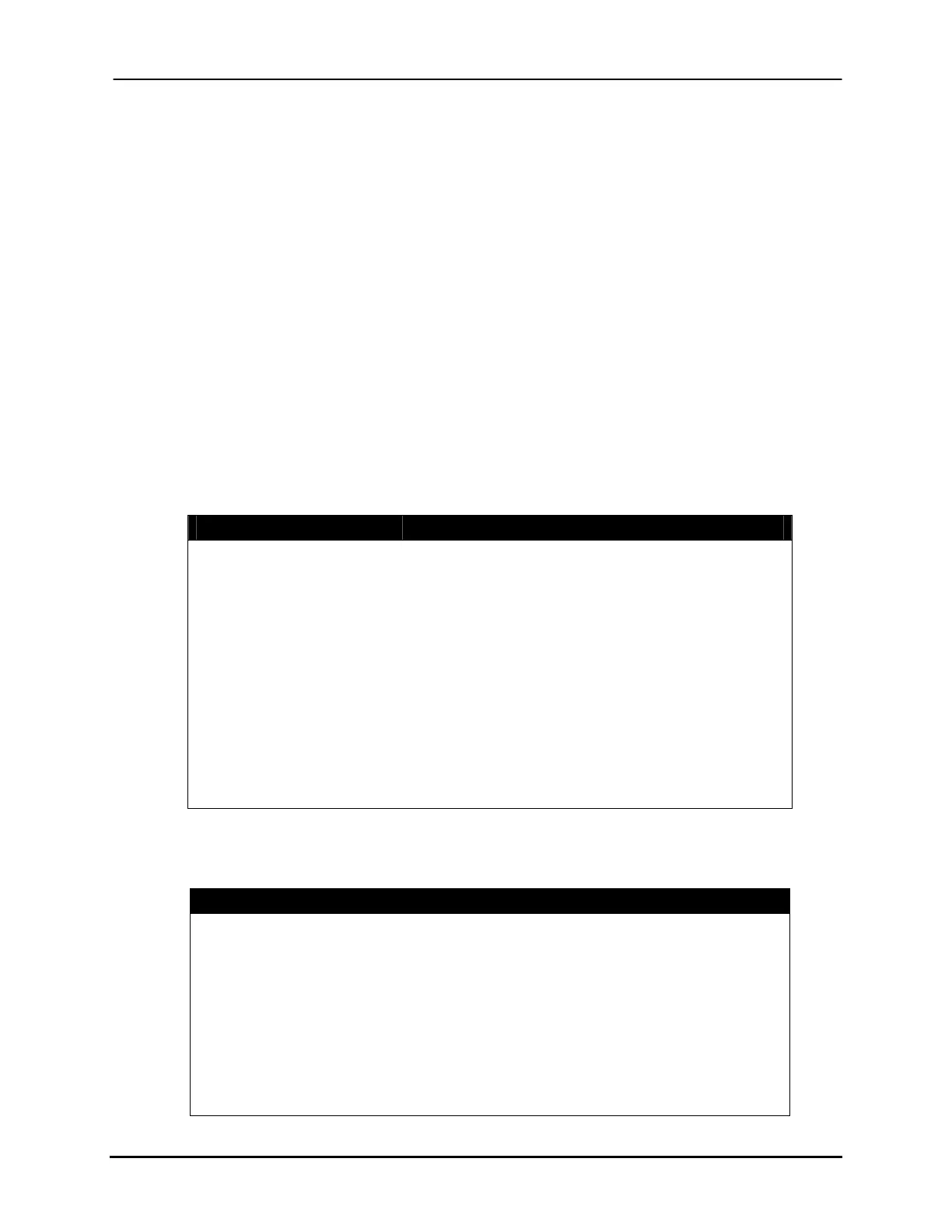

Table 2-3: DIP switch setting definitions for DIP S2.

Switch Position(s) Description

Position 1

On if Photo 1 is Normally Closed

Position 2 On if Photo 2 is Normally Closed

Position 5, 6 Feedback Encoder Resolution as follows

5:6 = Off:Off 660 DPI

5:6 = On:Off 600 DPI

5:6 = Off:On Not Used

5:6 = On:On Not Used

Position 7, 8 Follower Encoder Resolution as follows

7:8 = Off:Off 660 DPI (Or for last Transport)

7:8 = On:Off 600 DPI

7:8 = Off:On Not Used

7:8 = On:On Not Used

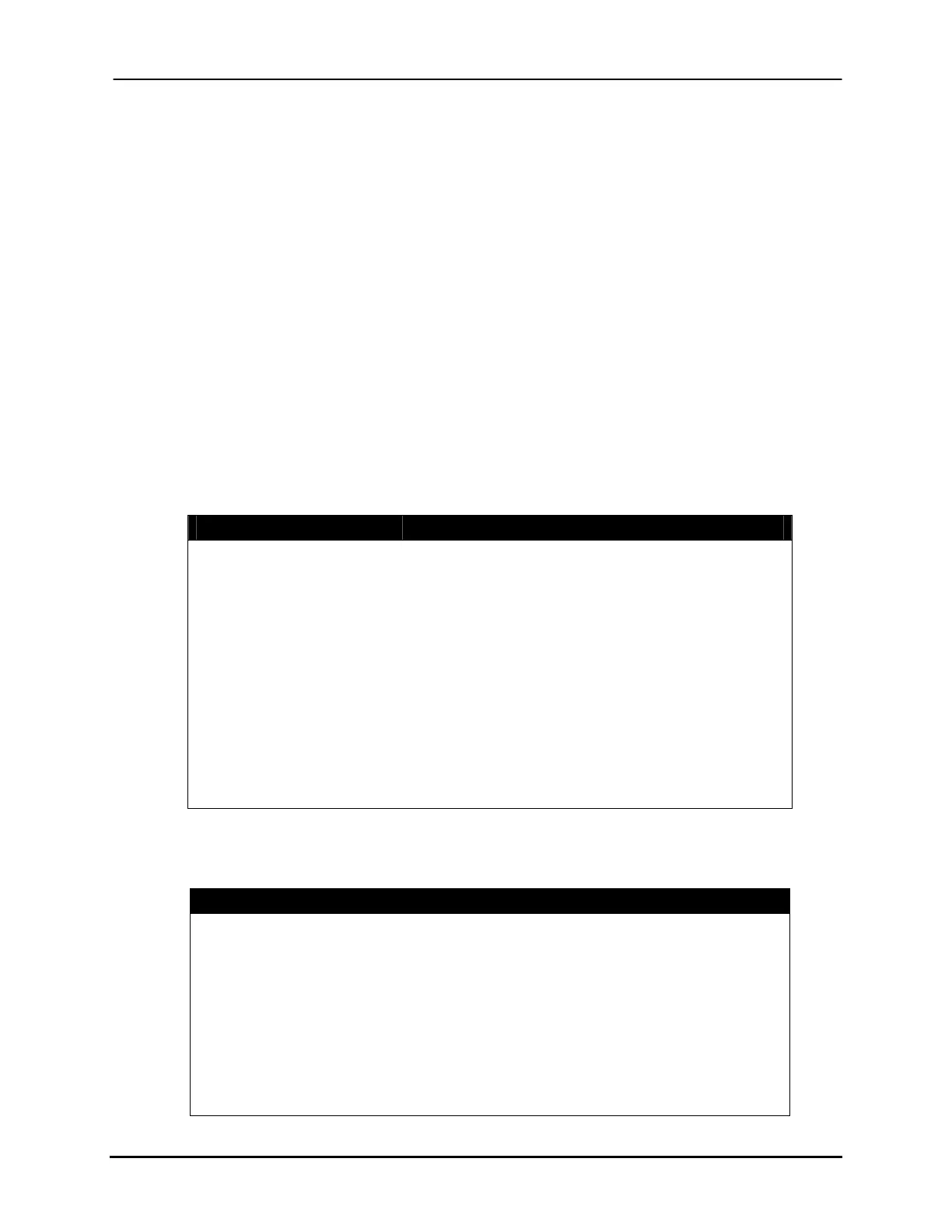

Table 2-4:

DIP switch setting definitions for DIP S3.

Switch Position(s) Description

Position 1

On to calibrate for 0 m/s

Position 2

On to calibrate for 1 m/s

Position 3

On to calibrate for 17 inch pitch

Position 4

On for “Follower” operating mode

Position 5

On for “Gap Control” operating mode

Position 6

Not Used

Position 7

Not Used

Position 8

On for “Master Follower” operating mode

Note: Only 1 switch can be enabled at any given time for DIP S3.

Buskro Ltd. BK730-2 Tabber

Loading...

Loading...