69

MicroDock II

Calibration

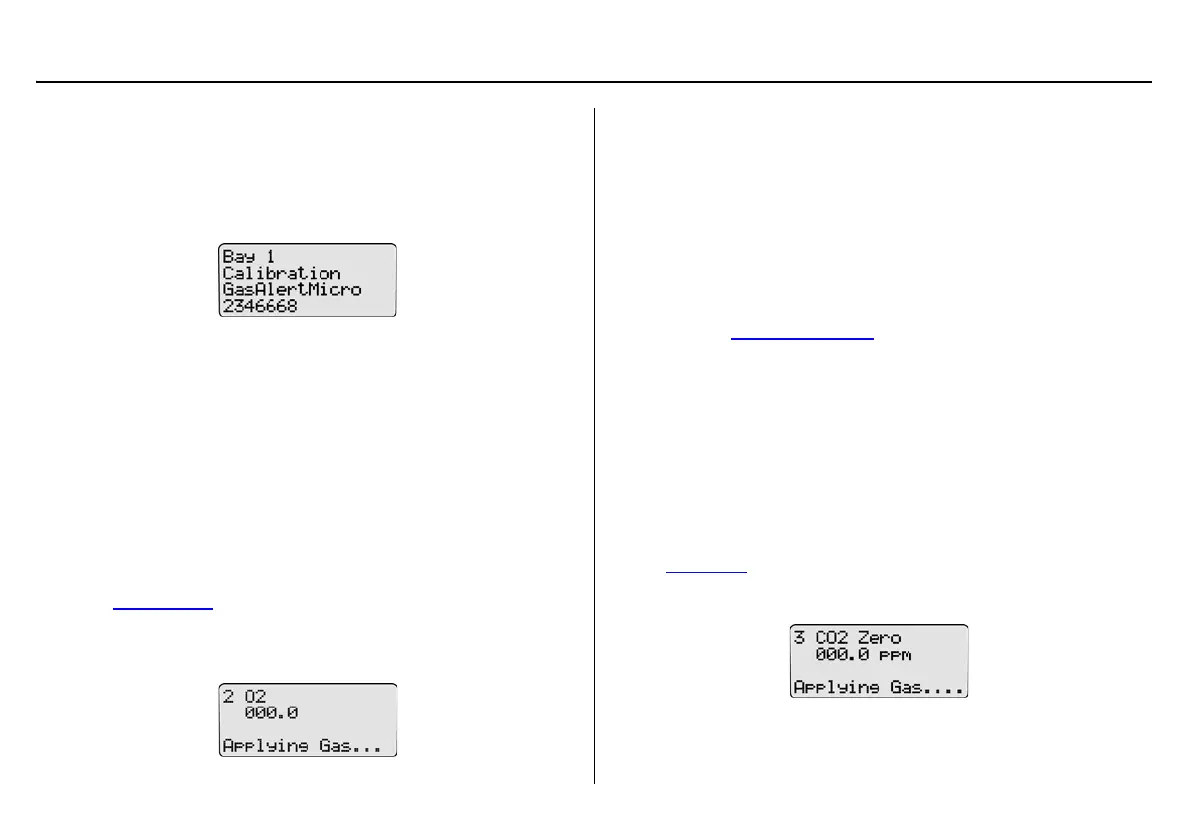

The base station begins the calibration and displays the

• docking module,

• test being performed,

• detector type, and

• detector serial number.

Note

The GasAlertMicro 5/PID/IR beeps and flashes two times when

calibration begins. The GasAlertMicroClip, GasAlertMax XT,

and GasAlertQuattro beep and flash once.

a Important

If the Automatic Datalog Download (GasAlertMicroClip,

GasAlertMax XT, GasAlertQuattro only) is enabled in Fleet

Manager II, data transfer automatically begins during the purge.

Do not remove the detector until the DATA TRANSFER PASS LED

lights, otherwise the transfer will fail.

5. If there is a gas conflict or a selected gas cannot be found, refer

to Gas Conflicts

.

6. If there are no gas conflicts, the base station then applies the

gas.

If more than one gas is being applied, the base station performs

a purge between each gas. Depending upon the gas type, the

purge time(s) will vary.

Note

If Automatic Datalog Download is enabled in Fleet Manager

II, GasAlertMicroClip, GasAlertMax XT, and GasAlertQuattro

automatically deactivate after the transfer is complete. To

bypass the shutdown, remove the detector within 15 seconds

after the DATA TRANSFER PASS LED lights.

7. Refer to Calibration Results

.

GasAlertMicro 5 IR with CO

2

Sensor

Note

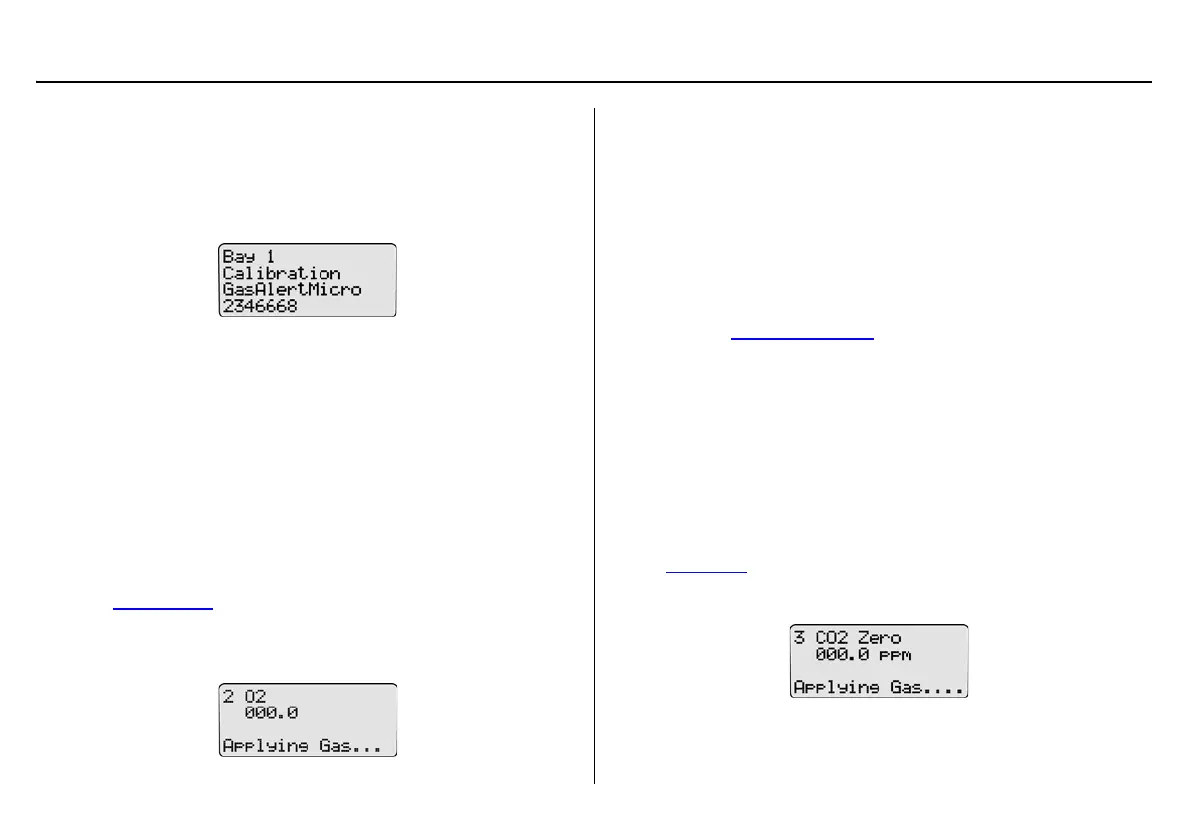

If calibrating a GasAlertMicro 5 IR detector, the base station

automatically zeroes and then calibrates the CO

2

sensor first.

1. The base station zeroes the CO

2

sensor. The CO

2

sensor can

only be zeroed using nitrogen (N

2

).

Ensure N

2

has been configured to an inlet. If required, refer to

Inlet Setup

.

2. The base station applies the gas.

Loading...

Loading...