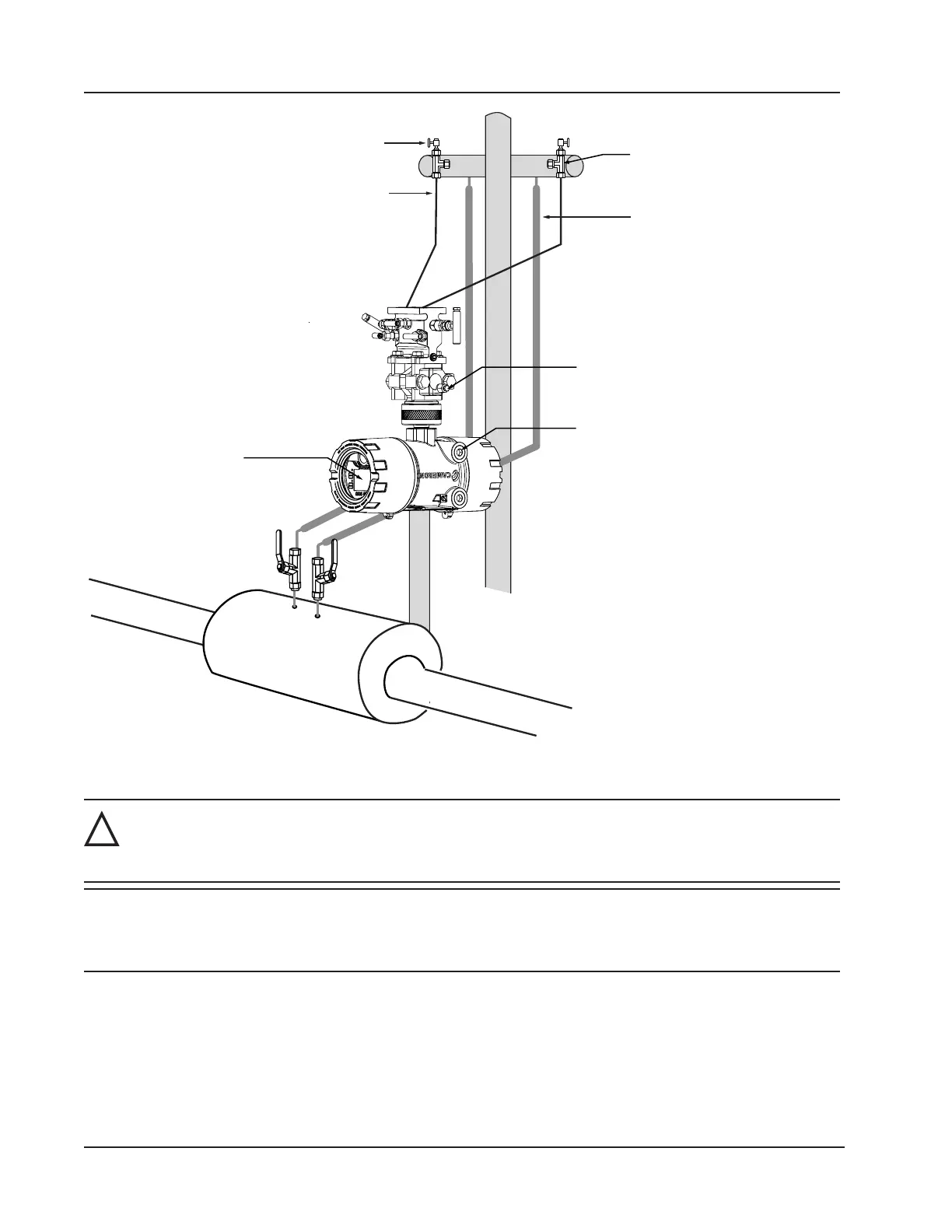

3/4 in. conduit connection for

input/output & communications

Cold legs connect to manifold

(slope to eliminate air trap)

Condensate pot (pipe tee

with blowdown valve attached)

Long cold legs protect the sensor from

extreme process temperatures

Hot legs, insulated to within

1 ft of condensate pot

(1/2 in. diameter recommended)

Pipe tee (can be used to fill cold legs)

LCD orientation

auto-corrects when

device is inverted

MVT vent (can be used to fill cold legs)

Figure 2.12—Remote-mount steam run installation

!

WARNING: HAZARDOUS AREA USE. The Scanner 3100 is certied for hazardous area use only when

installed in accordance with applicable standards and local wiring practices. Carefully review

Hazardous Area Precautions, page 27, to determine specic installation requirements (cable glands, con-

duit seals, signal cable, RTD, etc.).

IMPORTANT When measuring steam, process connections must be designed to eliminate air pockets. This is

achieved by making sure all tubing in the cold legs slopes upward. A bottom-port MVT and block

manifold (shown in Figure 2.12) is recommended to help prevent air bubbles from being

trapped in the sensor.

1. Verify that the meter is properly installed in the ow line (per manufacturer’s instructions).

2. Mount the Scanner 3100 to a 2-in. pipe or to a at, vertical surface using bolts and the mounting holes in the enclo-

sure. A horizontal pipe is recommended, as additional hardware may be required for a vertical pipe mount to provide

clearance for the manifold block.

44

Section 2 Scanner 3100 EFM

Loading...

Loading...