152 Functional Description CG Drives & Automation, 01-5326-01r5

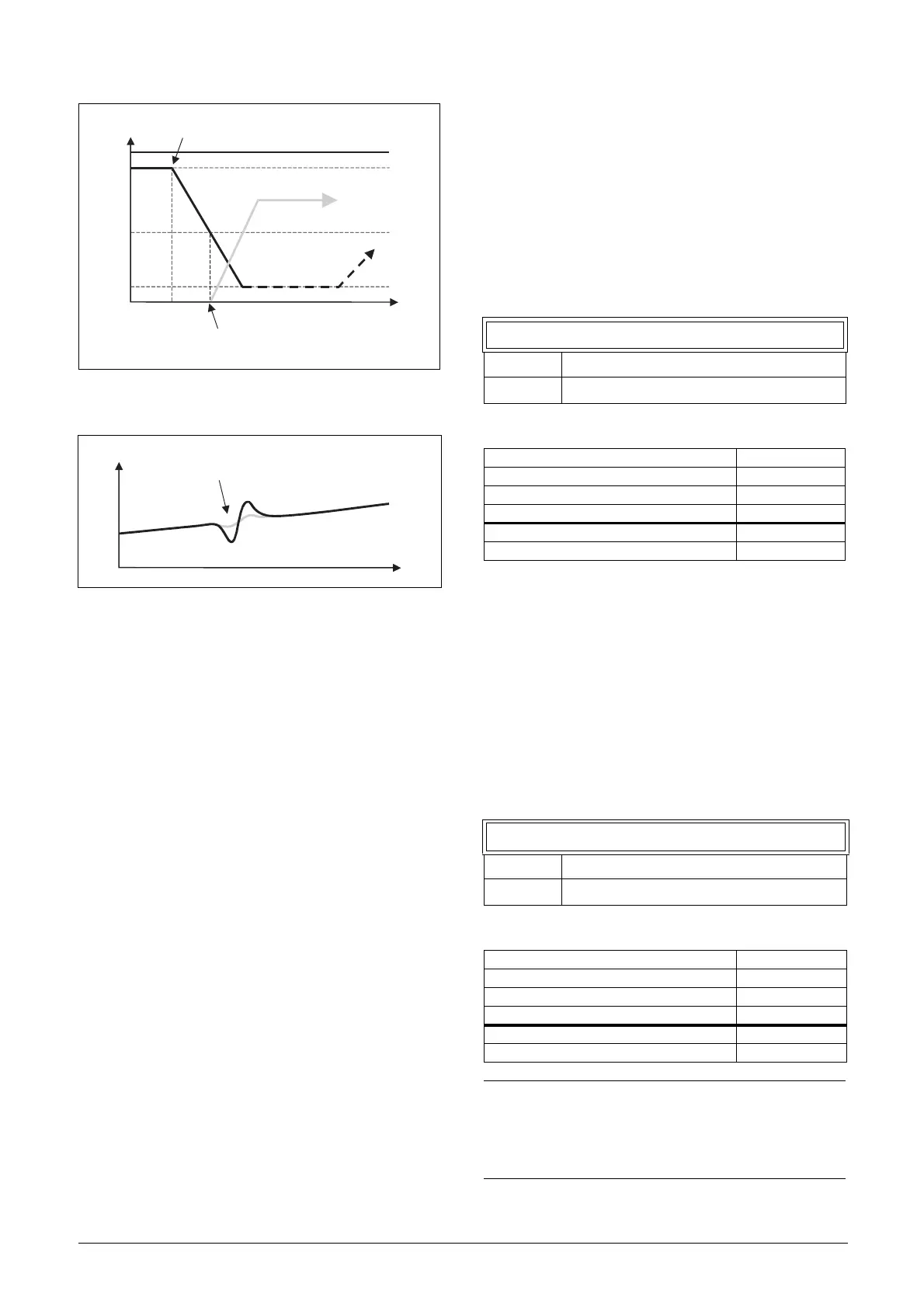

Fig. 119 Transition speed start

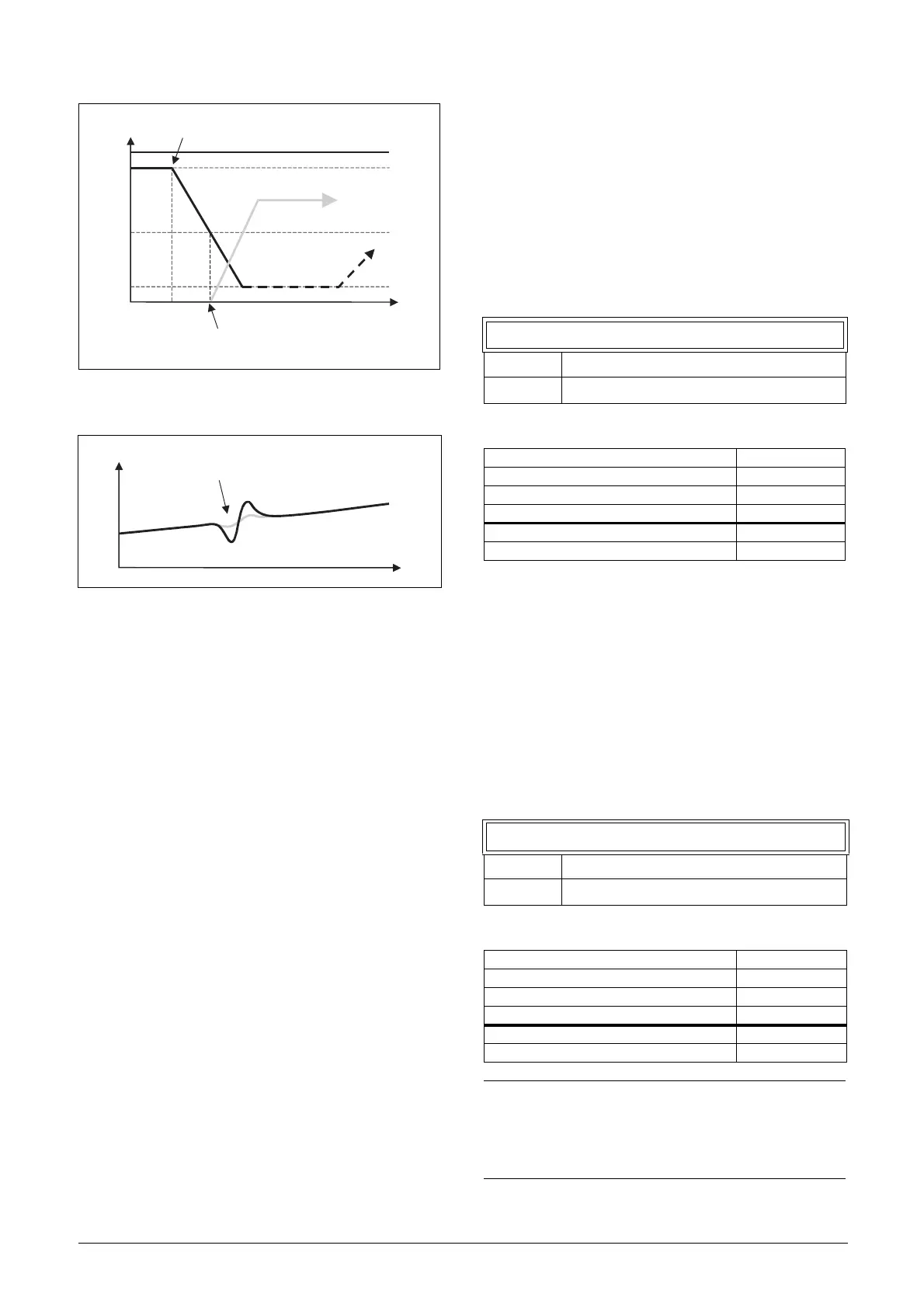

Fig. 120 Effect of transition speed

Settle Time Stop [39F]

The settle stop allows the process to settle after a pump is

switched off before the pump control continues. If an

additional pump is stopped D.O.L. (Direct On Line) or Y/

,

the flow or pressure can still fluctuate due to the 'rough'

start/stop method. This could cause unnecessary starting

and stopping of additional pumps.

During the Settle stop:

• PID controller is off.

• the speed is kept at a fixed level after stopping a pump

Communication information

Transition Speed Stop [39G]

The transition speed stop is used to minimize a flow/

pressure overshoot when shutting down an additional pump.

The setting depends on the dynamics of both the master

drive and the additional drives.

In general:

• If the additional pump has 'slow' start/stop dynamics,

then a higher transition speed should be used.

• If the additional pump has 'fast' start/stop dynamics,

then a lower transition speed should be used.

Communication information

Speed

Actual

Trans

Min

Switch on

procedure starts

Additional pump

Master pump

Flow/Pressure

Actual start

command of next

pump (RELAY)

Flow/Pressure

Transition speed

decreases overshoot

Time

39F Settle Stop

Default: 0 s

Range: 0–999 s

Modbus Instance no/DeviceNet no: 43175

Profibus slot/index 169/79

EtherCAT and CANopen index (hex) 4c67

Profinet IO index 19559

Fieldbus format Long, 1=1 s

Modbus format EInt

39G TransS Stop

Default: 60%

Range: 0-100% of total min speed to max speed

Modbus Instance no/DeviceNet no: 43176

Profibus slot/index 169/80

EtherCAT and CANopen index (hex) 4c68

Profinet IO index 19560

Fieldbus format Long, 1=1%

Modbus format EInt

NOTE: If set to 0 %, the transition speed when

stopping pumps, is ignored and no speed adaption is

made.

I.e. the slave pump is stopped directly and speed of

the master pump is continued.

Loading...

Loading...