66 Main Features CG Drives & Automation, 01-5326-01r5

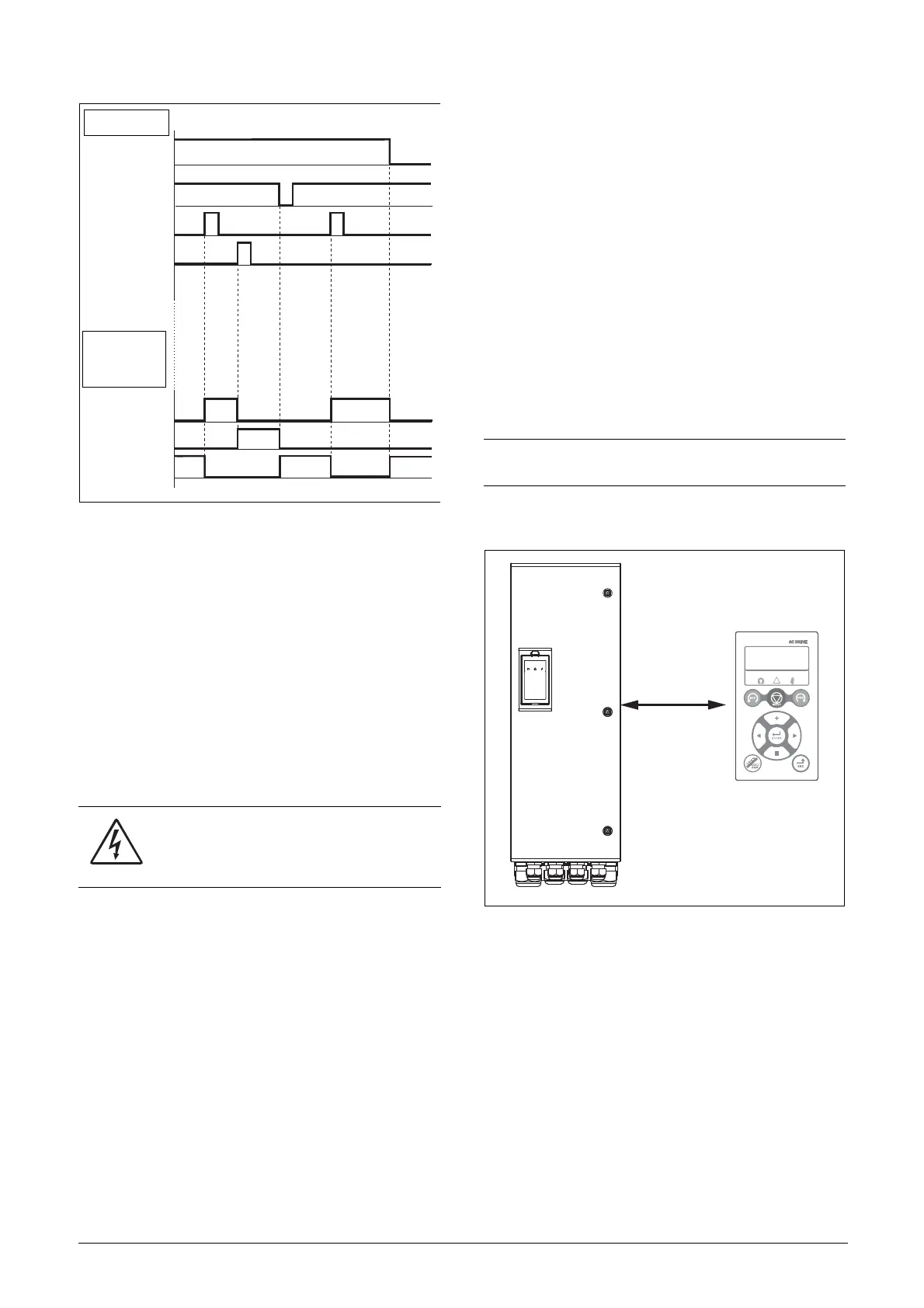

Fig. 74 Input and output status for edge-control

7.3 Performing an

Identification Run

To get the optimum performance out of your AC drive/

motor combination, the AC drive must measure the

electrical parameters (resistance of stator winding, etc.) of

the connected motor. See menu [229] “Motor ID-Run”.

It is recommended that the extended ID run is used before

the motor is installed in the application.

If this is not possible, the short ID run should be used.

7.4 Using the Control Panel

Memory

Data can be copied from the AC drive to the memory in the

control panel and vice versa. To copy all data (including

parameter set A-D and motor data) from the AC drive to the

control panel, select Copy to CP[234], Copy to CP.

To copy data from the control panel to the AC drive, enter

the menu [245], Load from CP and select what you want to

copy.

The memory in the control panel is useful in applications

with AC drives without a control panel and in applications

where several AC drives have the same setup. It can also be

used for temporary storage of settings. Use a control panel to

upload the settings from one AC drive and then move the

control panel to another AC drive and download the

settings.

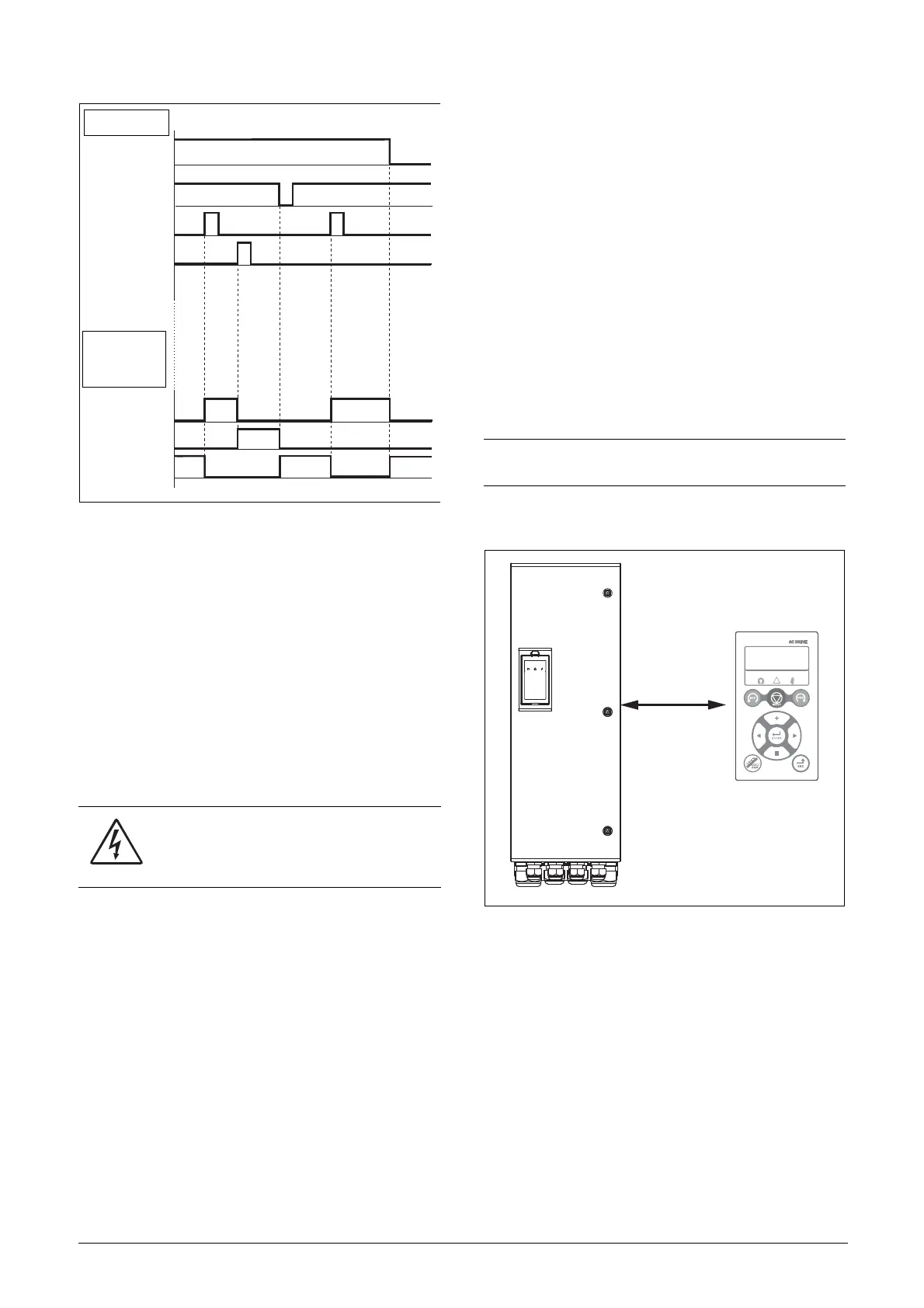

Fig. 75 Copy and load parameters between AC drive and

control panel

WARNING!

During the extended ID RUN, the motor shaft

will rotate. Take safety measures to avoid

unforeseen dangerous situations.

INPUTS

ENABLE

STOP

RUN R

RUN L

OUTPUT

STATUS

Right rotation

Left rotation

Standstill

NOTE: Load from and copy to the AC drive is only

possible when the AC drive is in stop mode.

Loading...

Loading...