Manual Operation

3.3.7.5.2 SETUP

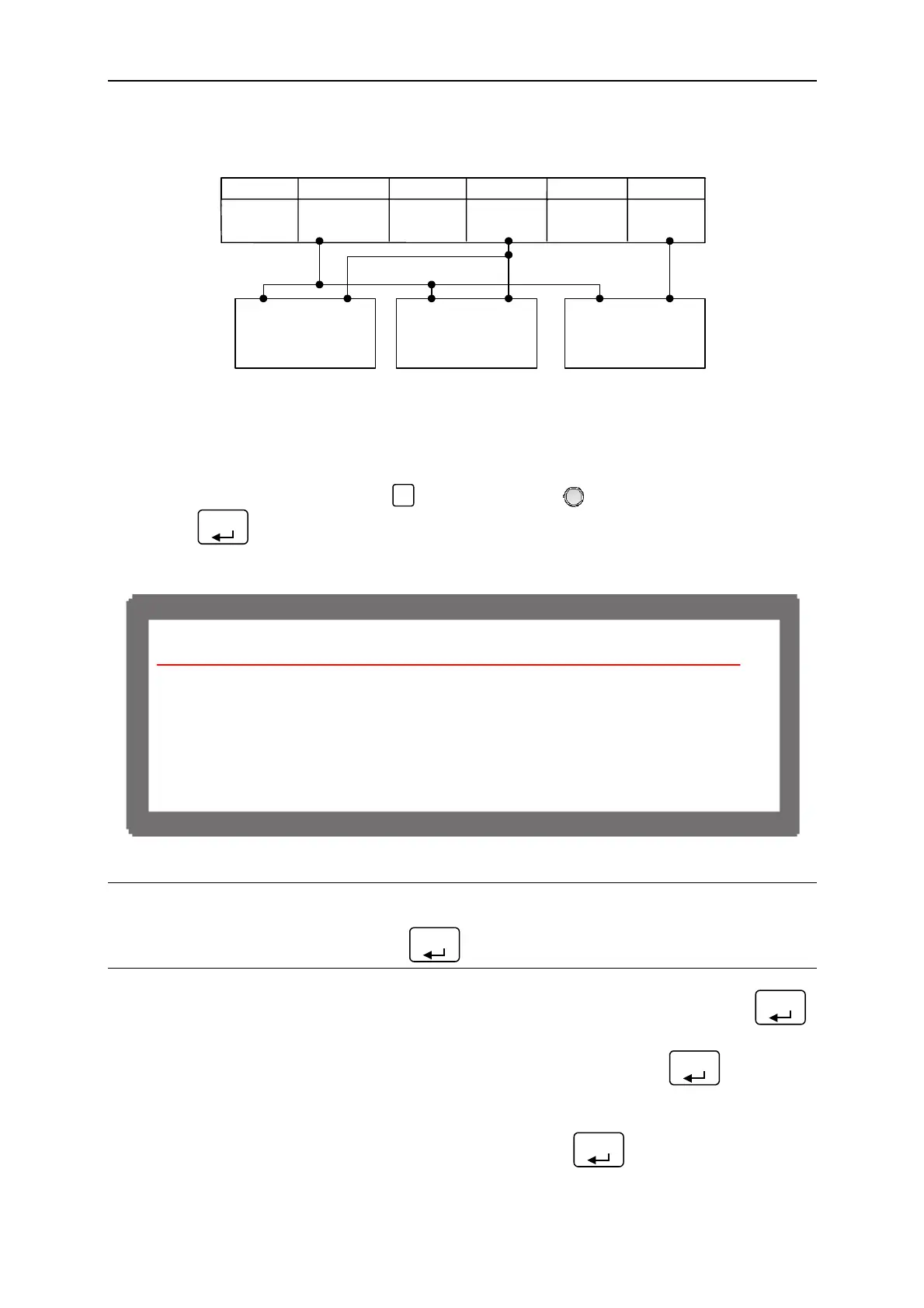

123456

+12VA APIGND V SET I SET V

MEAS.

I

MEAS.

+

DC Power

Supply

DVM1 DVM2

− +

Figure 3-100

3.3.7.5.3 Calibration Procedure (Example: Model 62012P-80-60)

(1) In CALIBRATION page, press “

4

” or turn “Rotary” (

) knob to set CHOICE = 4.

(2) Press “

ENTER

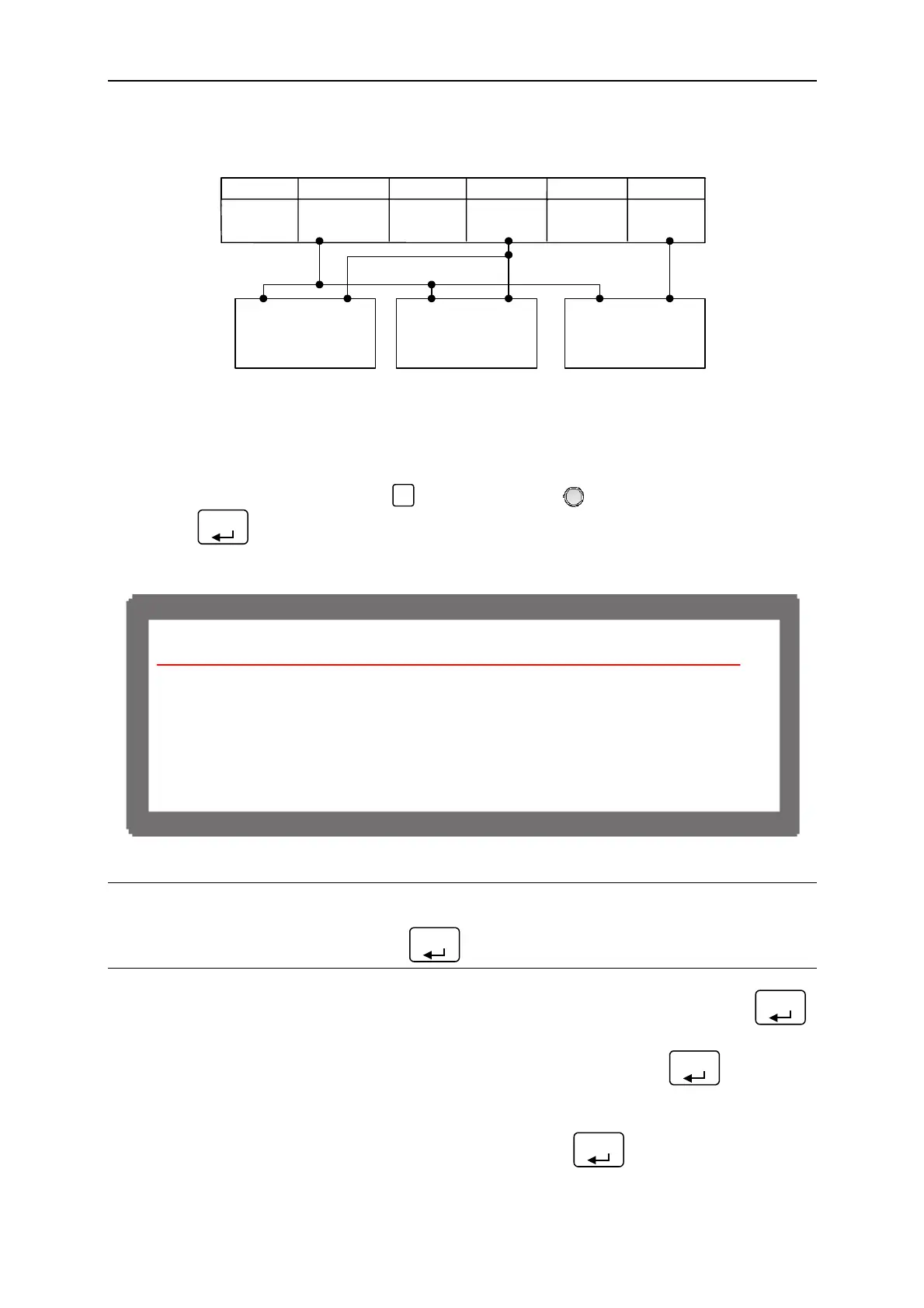

” to confirm entering into APG Voltage Calibration options as Figure 3-101

shows.

[APG CU

RENT CAL I B

T I O N ]

C H E C

A P G C O N N E C T I O N A N D P

ESS [ E N T E

]

( S E T ) I N P U T V O L T A G E F O R S E T T I N G = 0 . 5

C T U

L A P G I N P U T V O L T A G E = 0 . 6 6 V

( S E T ) I N P U T V O L T A G E F O R S E T T I N G = 8 . 0

C T U

L A P G I N P U T V O L T A G E = 8 . 6 8 V

Figure 3-101

NOTICE

When entering into the CALILBRATION page, be sure to check the interface connection on

the rear panel is correct and then press “

ENTER

” to start calibration.

(3) When in the APG Current Calibration pages and the connection is correct, press “

ENTER

”

to confirm.

(4) It will ask users to input about 0.5V voltage signal (Pin 4), and press “

ENTER

” the cursor

will stop at position [1] as Figure 3-102 shows. Adjust the Power Supply to 0.5V±0.2V

and use DVM1 to measure the reading of Power Supply. Input the voltage (2 digits after

decimal point) read by DVM 1 to position [1] and press “

ENTER

” to confirm.

3-61

Loading...

Loading...