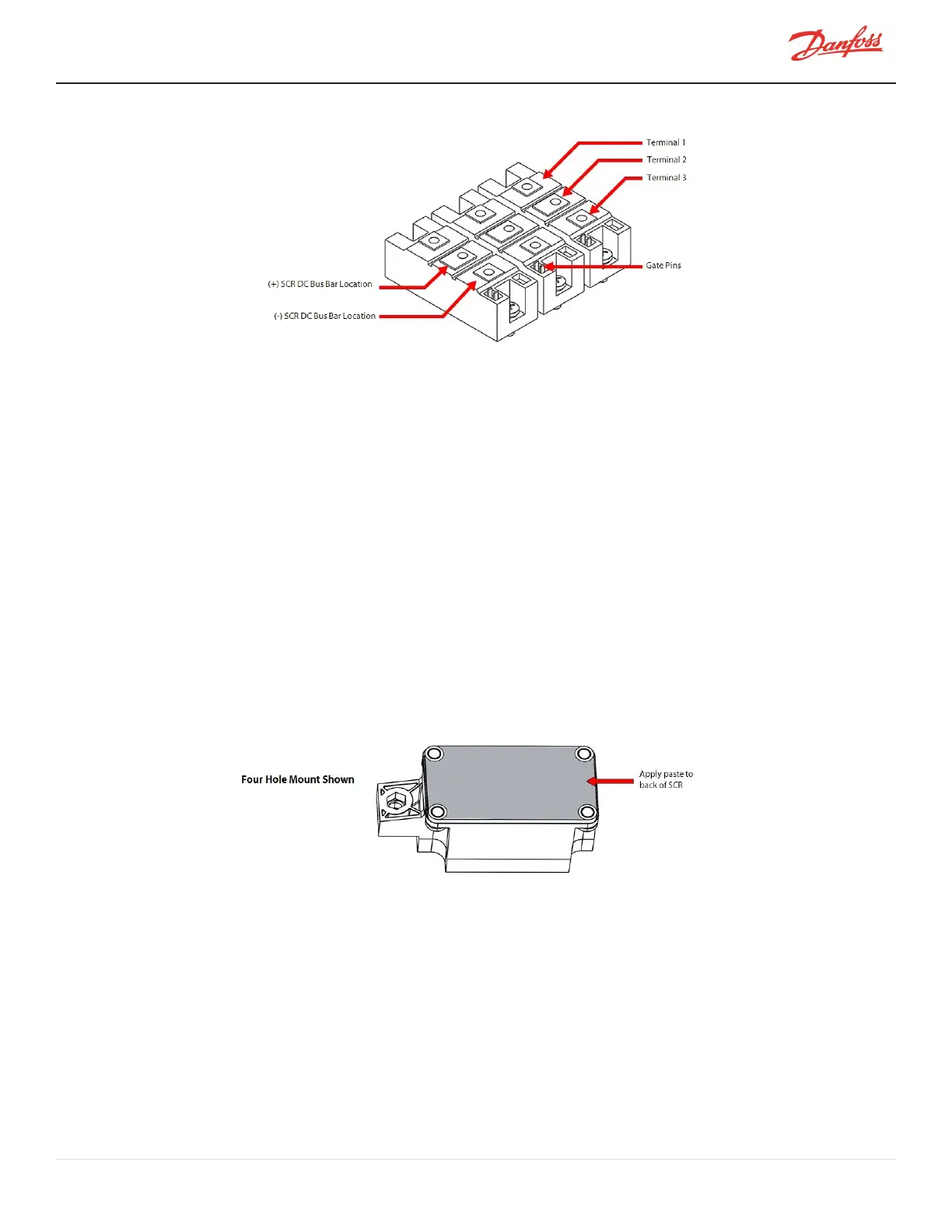

Figure 4-165 Bus Bar Locations - TTS300/TGS230

11. Torquethesix(6)M6x16SCRtoSCRCoolingManifoldfastenersto5Nm(44in.lb.).

12. Torquethesix(6)M6x16SCRBusBarfastenersto5Nm(44in.lb.).

13. Torquethetwo(2)CapacitorDCBusBartoSCRBusBarfastenersto10Nm(7ft.lb.).

14. Mountthethree(3)fuseblockassembliesontopoftheTerminalBlockAdapter,theninstallthetwo(2)

fastenersforeachofthethree(3)fuseblockassembliesandtorqueto4Nm(35in.lb).

15. Installthethree(3)M6x16fastenersthatconnectthefast-actingfusestotheSCRsandtorqueto5Nm

(44in.lb).

16. InstallthemainsinputcablestotheTerminalBlockandtorqueto20Nm(15ft.lb.).

17. ContinuetoSection4.18.3.6SCRGeneralInstallationonpage156.

4.18.3.5 SCR Installation - TTS/TGS/TTH/TGH (Except TTS300/TGS230)

1. CleanthecontactsurfacesofSCRCoolingManifold.

2. IftheSCRsaretobereused,cleantheirmountingsurface(backside)toensurethesurfaceisfreeofany

contaminants.

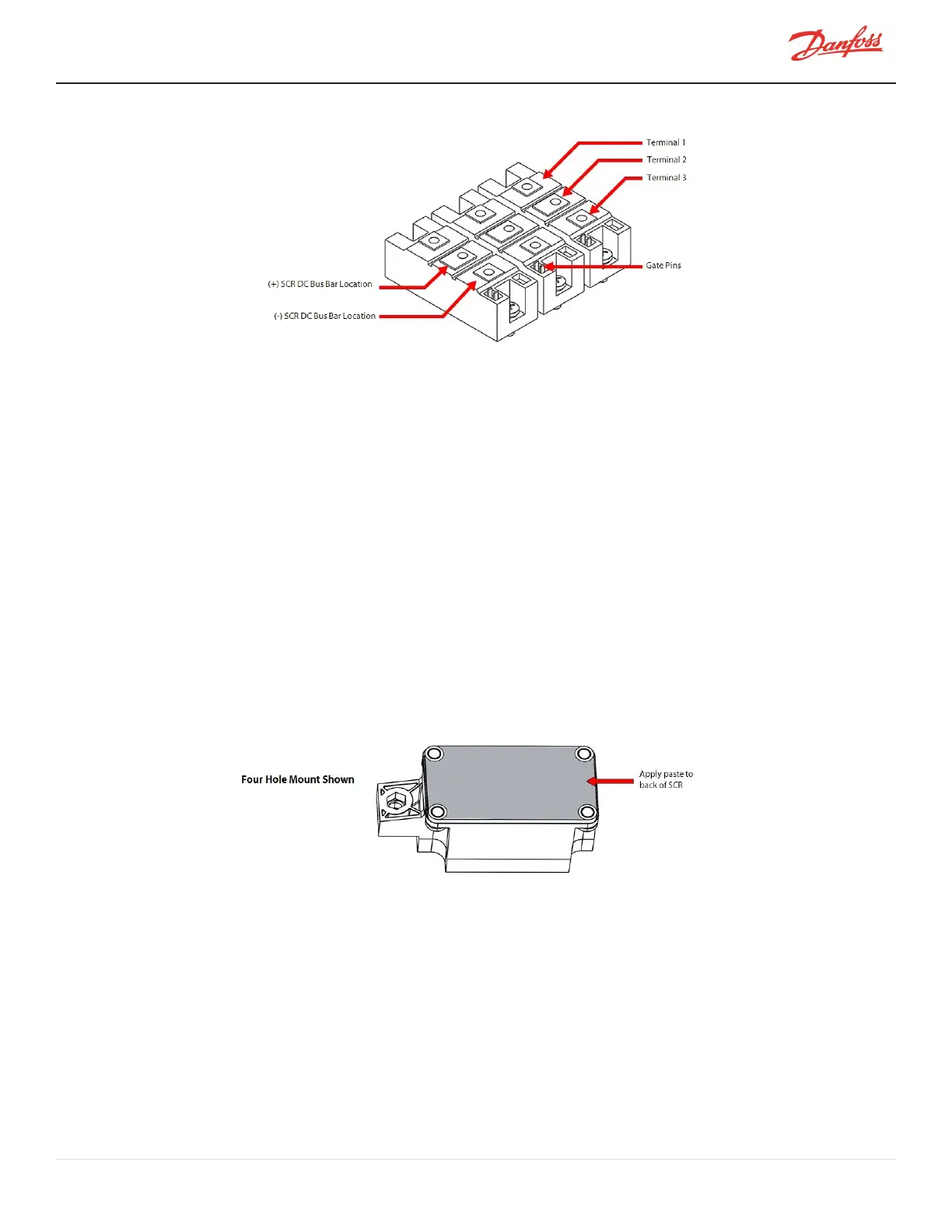

3. SpreadathinanduniformcoatofDowCorningSiliconeHeatSinkpaste(orequivalent)entirelyover

thebottomofeachSCRsurface.RefertoFigure4-166SCRHeatSinkPasteApplication-

TTS/TGS/TTH/TGH(ExceptTTS300/TGS230).

Figure 4-166 SCR Heat Sink Paste Application - TTS/TGS/TTH/TGH (Except TTS300/TGS230)

4. Installthethree(3)SCRs.

a. ForRevisionFandearliercompressors,finger-tightenthe12M6x16fasteners,thentightenina

crisscrosspatternintwo(2)stages.RefertoFigure4-167SCRTorqueSequence-TTS/TGS/TTH/TGH

Rev.FandEarlier(ExceptTTS300/TGS230)onpage156.

o

Stage1:Tightento2Nm(18in.lb.)

o

Stage2:Tightentoafinaltorqueof5Nm(44in.lb.)

b. ForRevisionHcompressors,tightenthesix(6)M6x16fastenersto5Nm(44in.lb).

M-SV-001-EN Rev. H-1/23/2023 Page 155 of 294

Loading...

Loading...