Chapter 6.0 Maintenance

6.1 Preventative Maintenance Tasks

Table6-1PreventativeMaintenanceTasksidentifiestasksthatshouldbeperformedonaregularbasistomaintain

optimalperformanceofthesystem.

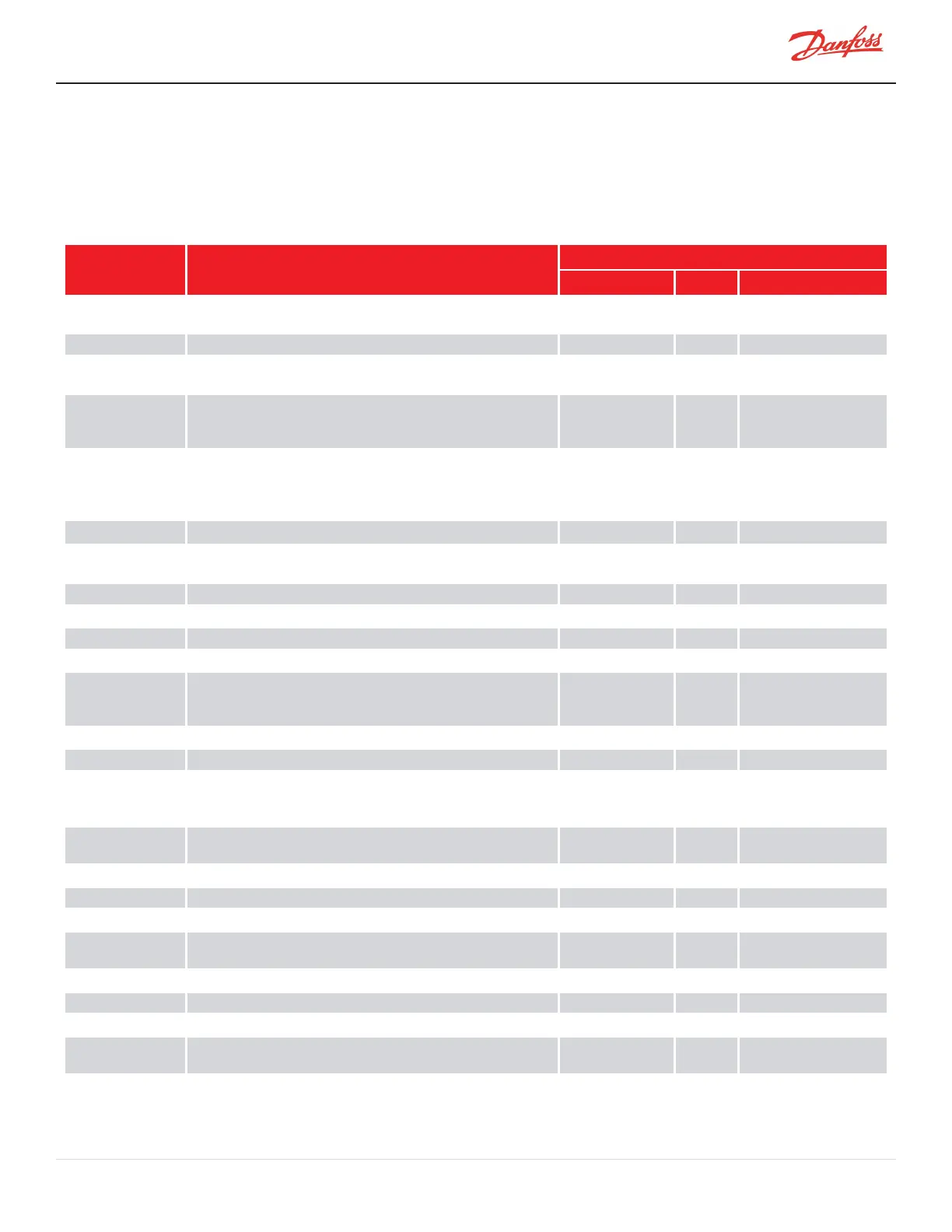

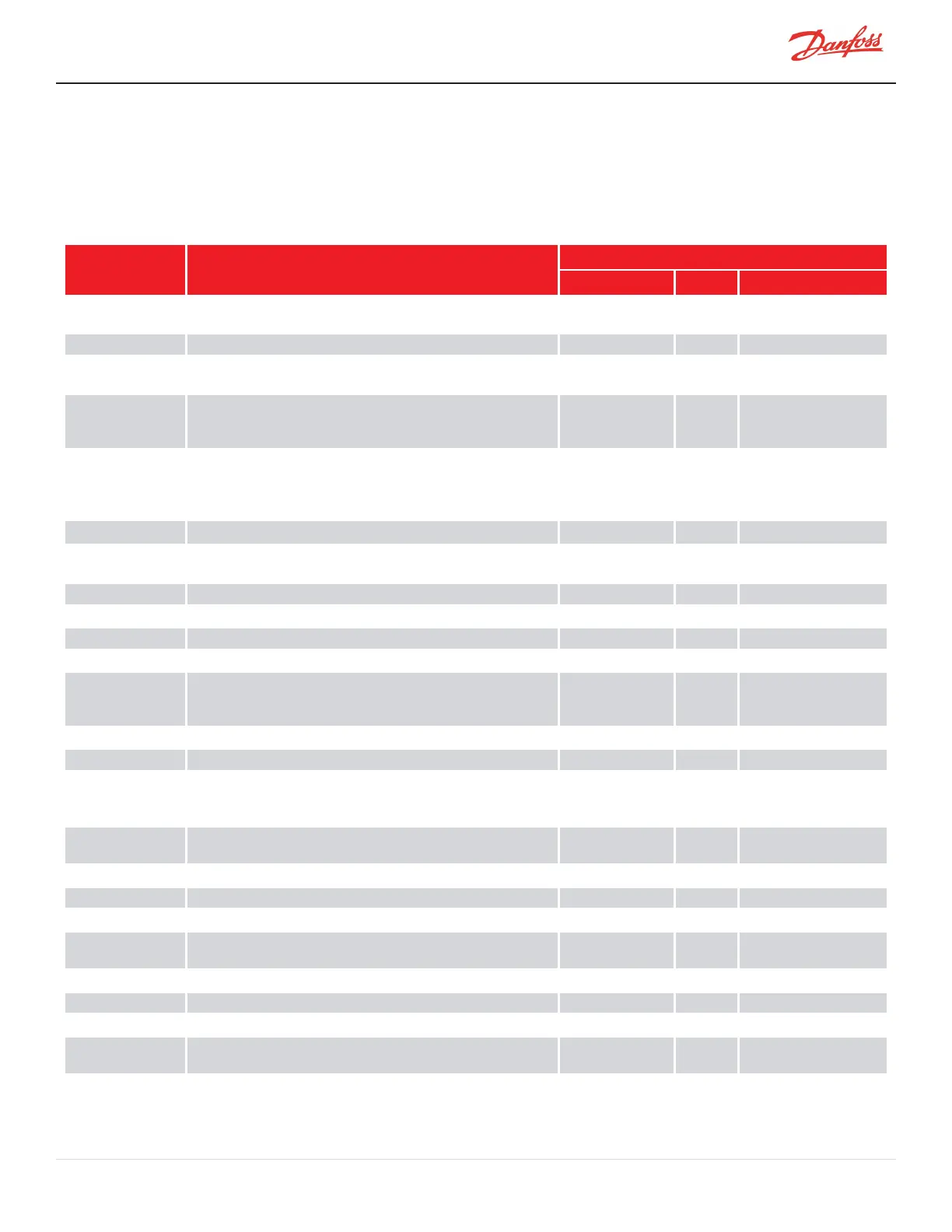

Table 6-1 Preventative Maintenance Tasks

Item Task

Frequency

6 Months 12 Months Other

General

Inspections

Checkphysicalconditionofcompressor.

P

Checkforexcessivevibrationfromotherrotatingequipment.

P

Checkforoilinthesystem.Thecompressormustoperateinan

oil-freeenvironment.Ensurealloilisremovedfromthesystem.

P

Compressor

Inspections

ConnecttothecompressorusingtheServiceMonitoringTools

softwareanddownloadfaultandeventlogs.Reviewandsave

logsforfuturereference.

P

ConnecttothecompressorusingtheServiceMonitoringTools

softwareandperformacalibration.Donotsavethecalibrationto

EEPROMifthecompressorhasbeenoperatingcorrectly.Create

andsaveaCalibrationReportforfuturereference.

P

InspecttheCapacitorReliefMembrane.Replaceasnecessary.

P

Electrical

Inspections

Checkmainpowersupplyvoltages.

P

Ensureelectricalterminalsaretight.

P

Checkforsignsofhotspots/discolorationonpowercables.

P

Checkamperagesduringoperationareasperdesign.

P

CheckDCbusvoltage.

P

ReplaceDCCapacitorBusBarAssembly.(RefertoSection4.21DC

CapacitorBusBarAssemblyonpage165)

Energized:10

years/Denergized:5

years

Checkoperationofallsystemsafetydevicesandinterlocks.

P

Performmoisture-preventionmeasures.

P

ReplaceSoftStartfan.(RefertoSection4.14.8SoftStartFan

RemovalandInstallationonpage123)

5years,referto

CustomerNotification

B-CN-041-EN

Electronic

Inspections

Ensureallcommunicationcablesaresecure.

P

Ensureallelectronicmodulesaresecure.

P

CheckphysicalconditionofallexposedPCBs.

P

CheckallexposedPCBsfordustbuild-upandcleanifnecessary.

P

Checkdischargeandsuctionpressure/temperaturesensorsfor

accuracyagainstcalibratedpressure/temperaturegauges.

P

Refrigeration CheckoperationofIGVassembly.

P

Checksystemrefrigerantcharge.

P

Checksuperheat/levelcontrol,ifapplicable.

P

Checksystemandliquidlinetoensuresufficientsub-cooled

refrigerantisavailableatliquidlineadapter.

P

Verifydischargecheckvalveoperation.

Ifthereisbackwardgasflowimmediatelyafterstoppingthe

compressor,replacethecheckvalve.

P

M-SV-001-EN Rev. H-1/23/2023 Page 275 of 294

Loading...

Loading...