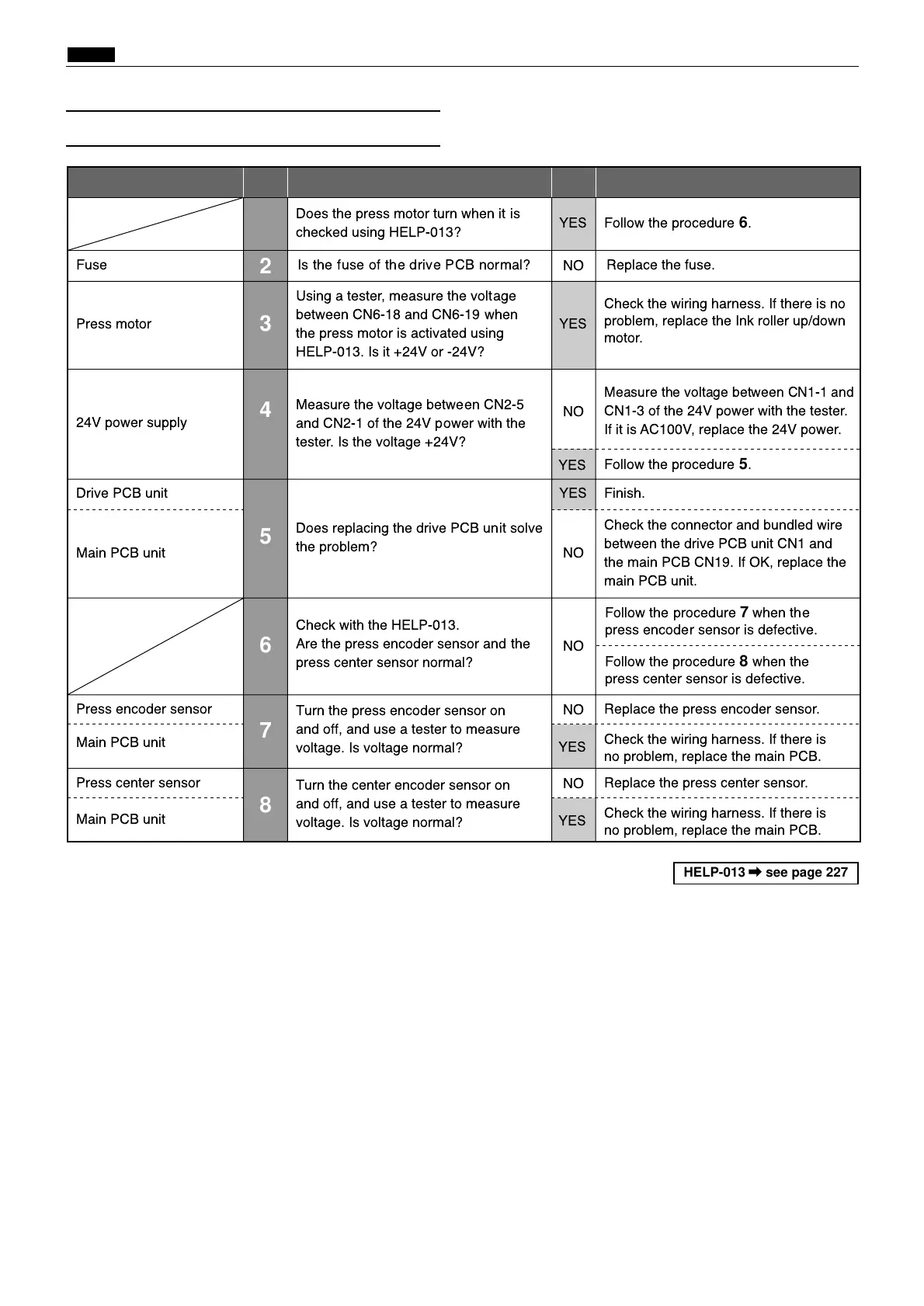

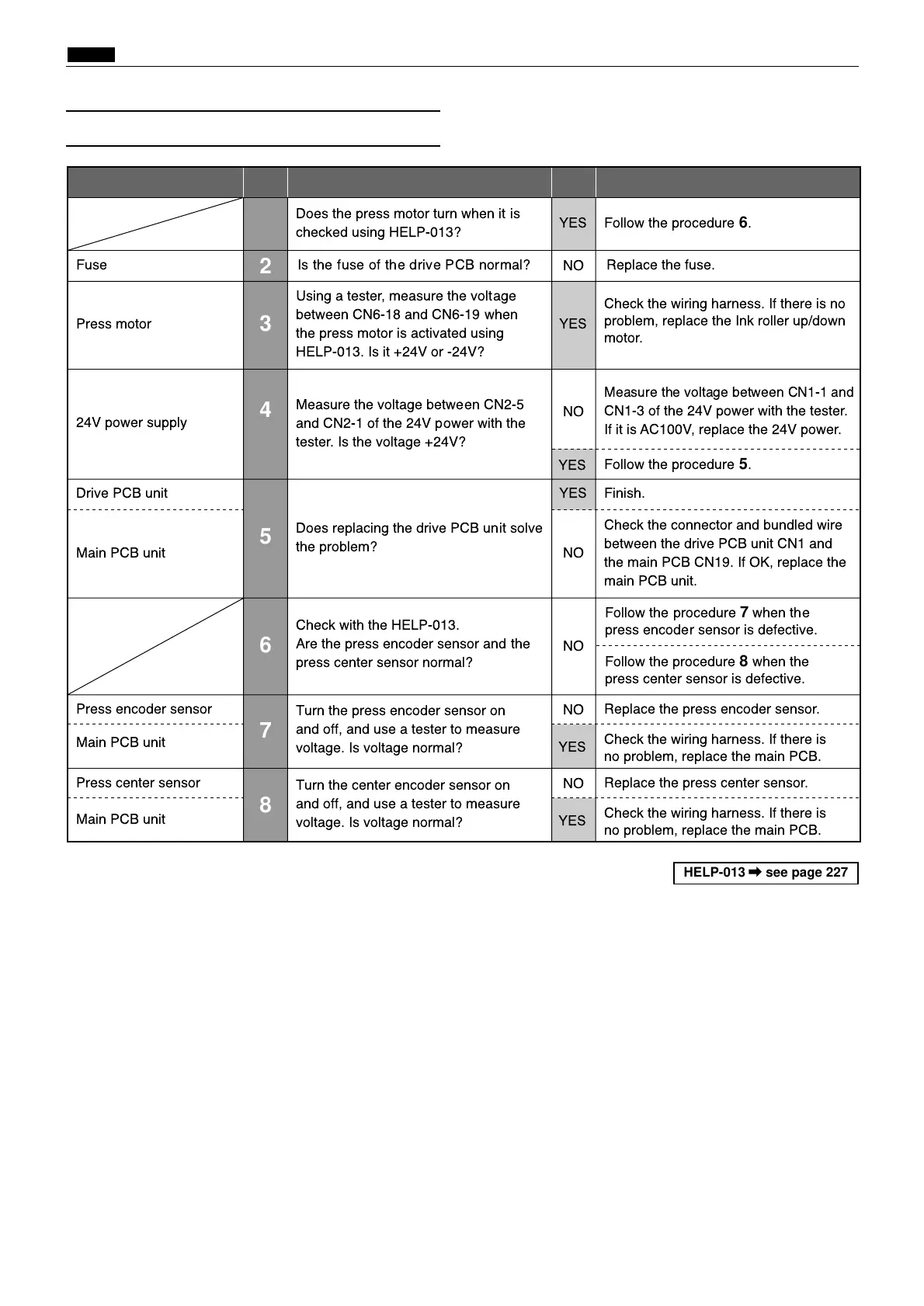

Cause/Detective section

Procedures

Result

CountermeasureItems to be checked

1

Does the press motor turn when it is

checked using HELP-013?

YES Follow the procedure

6

.

Press motor

3

Using a tester, measure the voltage

between CN6-18 and CN6-19 when

the press motor is activated using

HELP-013. Is it +24V or -24V?

YES

Check the wiring harness. If there is no

problem, replace the Ink roller up/down

motor.

Drive PCB unit

5

6

Does replacing the drive PCB unit solve

the problem?

YES Finish.

Main PCB unit NO

NO

Check the connector and bundled wire

between the drive PCB unit CN1 and

the main PCB CN19. If OK, replace the

main PCB unit.

Main PCB unit

Press encoder sensor

7

Turn the press encoder sensor on

and off, and use a tester to measure

voltage. Is voltage normal?

Turn the center encoder sensor on

and off, and use a tester to measure

voltage. Is voltage normal?

NO

Replace the press encoder sensor.

Check the wiring harness. If there is

no problem, replace the main PCB.

Follow the procedure

5

.

YES

YES

Main PCB unit

Press center sensor

NO

Replace the press center sensor.

Check the wiring harness. If there is

no problem, replace the main PCB.

YES

8

24V power supply

4

Measure the voltage between CN2-5

and CN2-1 of the 24V power with the

tester. Is the voltage +24V?

NO

Measure the voltage between CN1-1 and

CN1-3 of the 24V power with the tester.

If it is AC100V, replace the 24V power.

Fuse Is the fuse of the drive PCB normal? Replace the fuse.

2

NO

Check with the HELP-013.

Are the press encoder sensor and the

press center sensor normal?

Follow the procedure

7

when the

press encoder sensor is defective.

Follow the procedure

8

when the

press center sensor is defective.

Loading...

Loading...