90

m Drum Section

chap.2

Description

At times other than printing, the ink roller is separated from the inner surface of the drum by a fixed

clearance. During printing, however, the press roller rises and presses the ink roller into contact with the

drum inner surface, so that ink is supplied via the drum inner surface to the printing paper. This mechanism

prevents ink from being supplied to the drum inner surface if the printer is run without any paper.

When the master is detached in the platemaking process, ink on the drum surface is removed along with the

document, which means that in the first printing after the master is attached, there is a possibility of

insufficient ink on the drum surface, resulting in faint images.

To prevent such ink insufficiency when in the first printing, the machine is equipped with a mechanism for

raising and lowering the ink roller. Before paper is fed in, this mechanism pushes the ink roller against the

drum inner surface, so that ink is forcibly supplied immediately prior to the start of printing. As a result, the

images on the first sheet printed after platemaking are sufficiently bold.

Ink roller up and down operations are included as elements in the Fine Start mode, and therefore are

optimally controlled in accordance with room temperature, length of time out of use, number of sheets in last

run, etc.

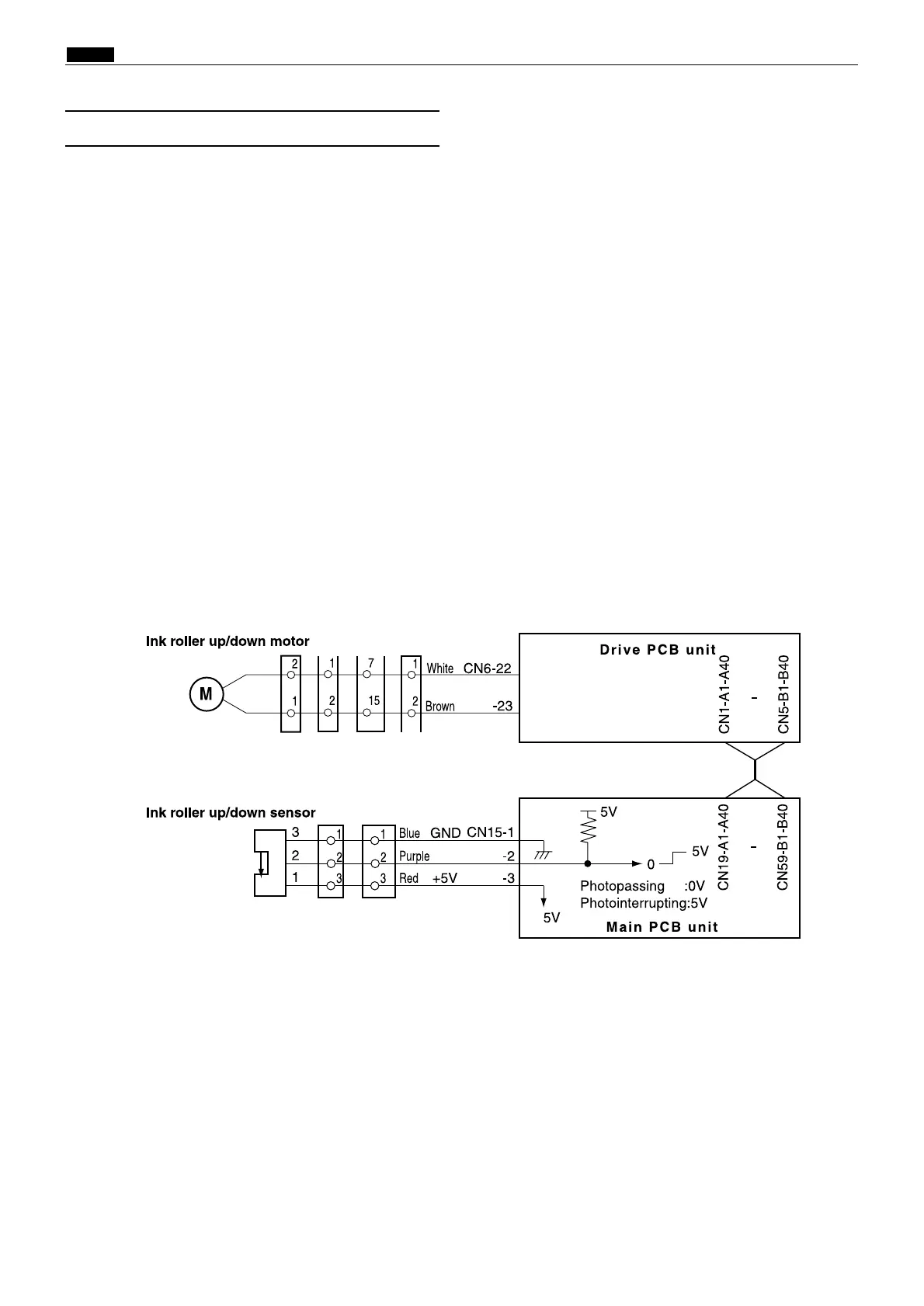

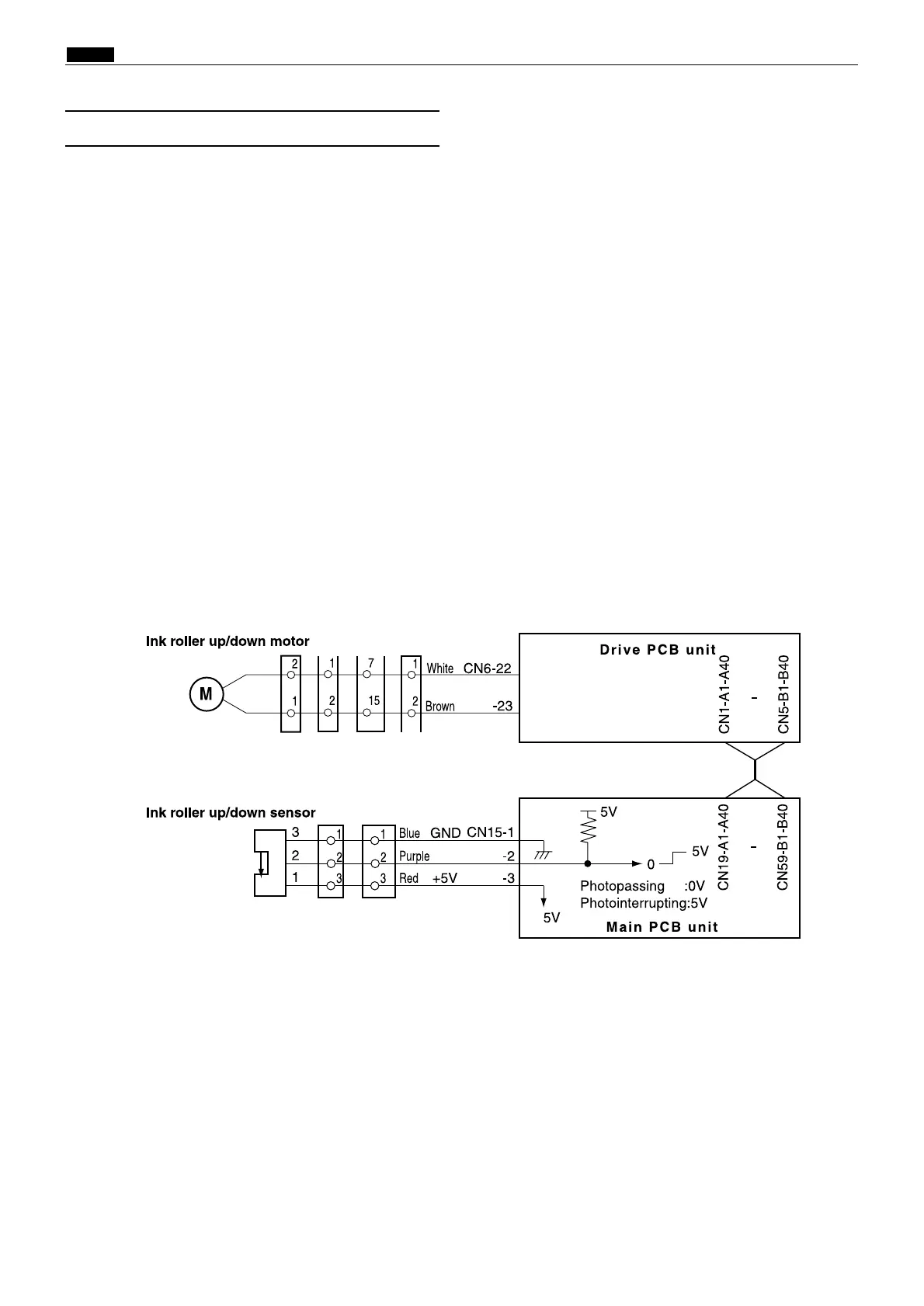

Circuit

(2) Ink Roller Up/Down Mechanism

R8S02E31e

Loading...

Loading...