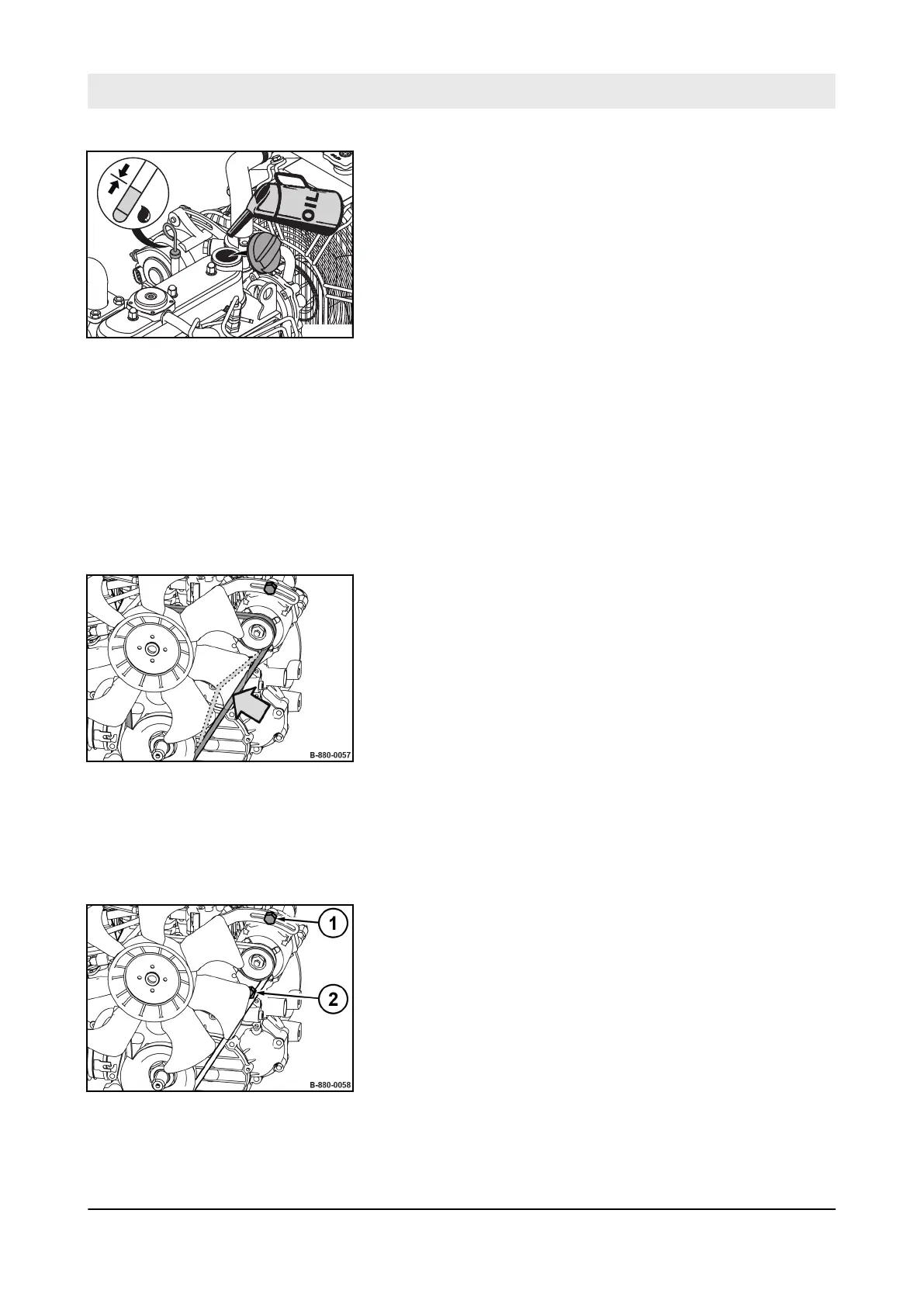

9. Clean the area around the filling port and the oil dipstick.

10. Remove the cap and fill with fresh engine oil.

11. Close the cap.

12. After a short test run, check the oil level on the oil dipstick; if

necessary, top up to the “MAX” mark.

13. Check the oil filter cartridge and drain plug for leaks.

14. Dispose of the oil and filters in line with environmental regula-

tions.

8.8.2 Checking, tensioning the V-belt

8.8.2.1 Checking the V-belt

Protective equipment:

n

Working clothes

n

Protective gloves

1.

Park the machine in secured condition

Ä

Chapter 6.5

„Parking the machine in secured condition“ on page 90.

2. Allow the engine to cool down.

3. Check the entire circumference of the V-belt for damage and

cracks.

4.

Replace a damaged or cracked V-belt

Ä

Chapter 8.9.1

„Replacing the V-belt“ on page 127.

5. Check with thumb pressure whether the V-belt can be

depressed more than 7 to 9 mm (0.28 – 0.35 inch) between

the V-belt pulleys, retighten if necessary.

8.8.2.2 Tightening the V-belt

Protective equipment:

n

Working clothes

n

Protective gloves

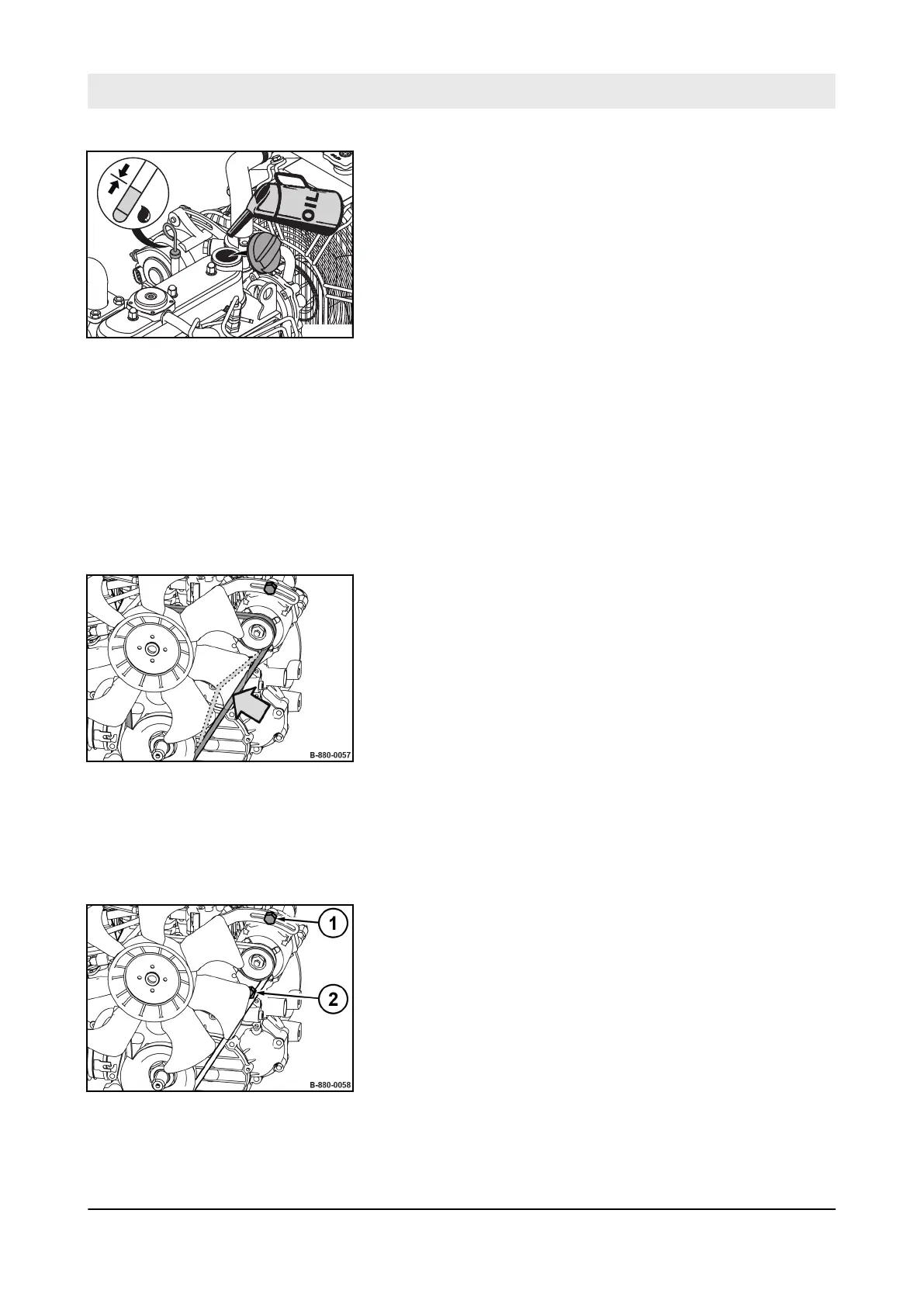

1. Loosen the tensioning screw (1) and the screw (2) on the

generator.

2. Press the generator towards the outside using a lever, until

the correct V-belt tension is reached.

3. Retighten clamping screw (1) and screw (2).

Fig. 139

Fig. 140

Fig. 141

Maintenance – Every 250 operating hours/annually

D.ONE

117

Loading...

Loading...