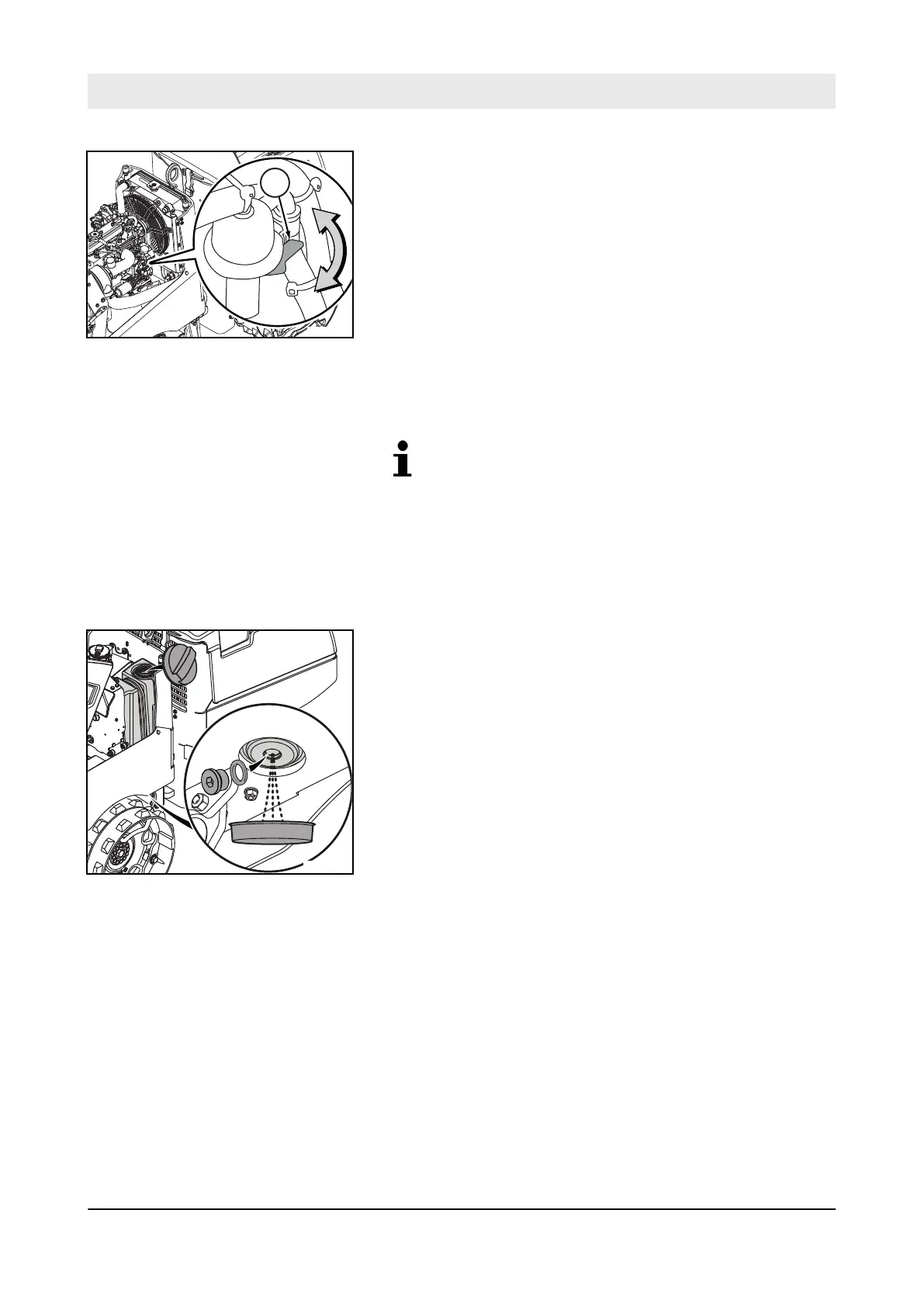

2. Operate the hand lever (1) on the fuel lift pump until fuel

flows out of the loosened bleed screw without air bubbles.

3. Collect the escaping fuel.

4. Tighten the bleeding screw.

5. Start the engine and run it for 5 minutes at idle speed.

6. Check the fuel pre-filter for leaks.

7. Dispose of collected fuel in line with environmental regula-

tions.

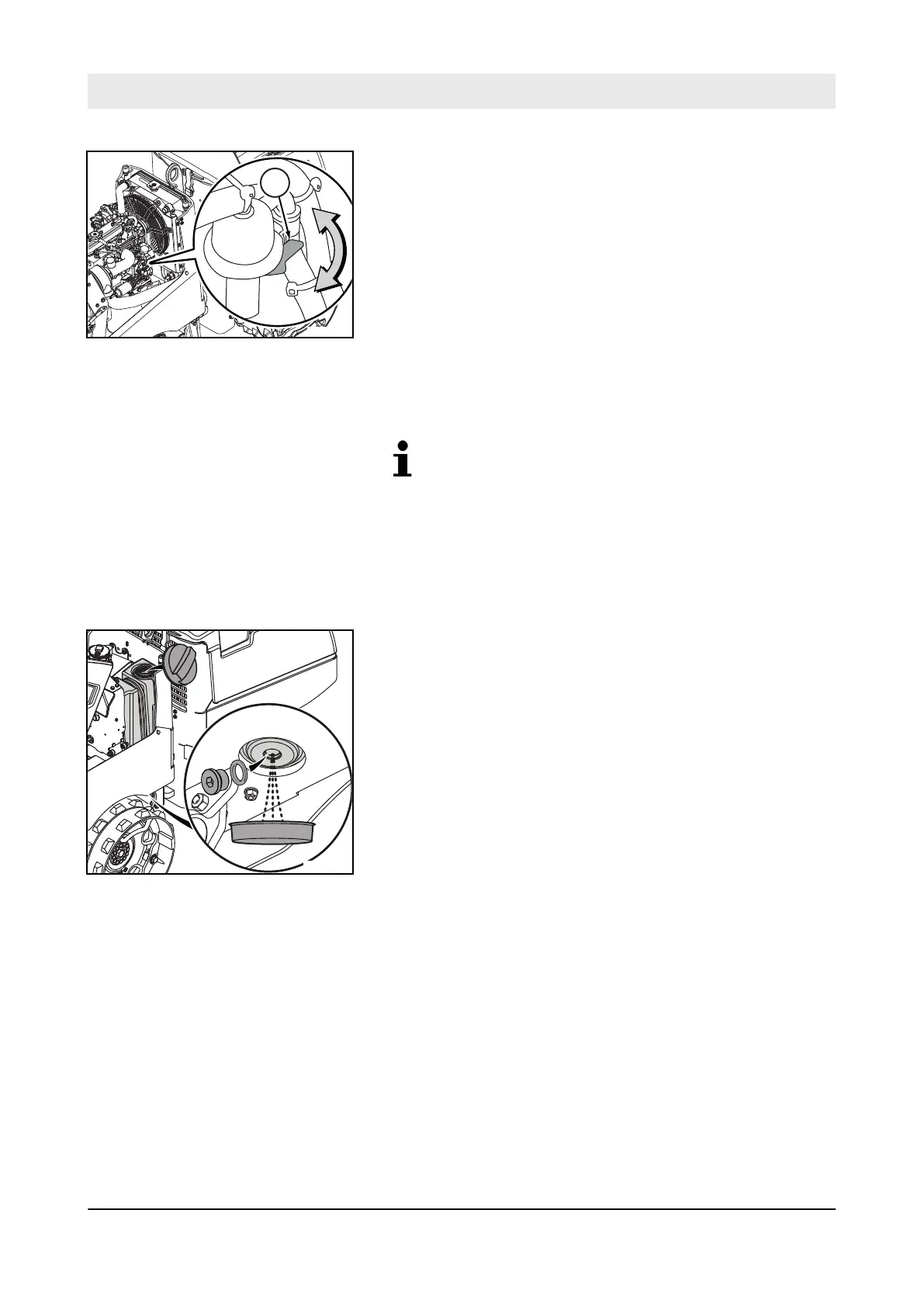

8.8.7 Draining the fuel tank sludge

The filling level of the fuel tank should not exceed

5.0 l (1.3 gal US) for draining purposes.

Protective equipment:

n

Working clothes

n

Safety shoes

n

Protective gloves

1.

Park the machine safely

Ä

Chapter 6.5 „Parking the machine

in secured condition“ on page 90.

2. Clean the area around the filler opening and remove the cap.

3. Unscrew the drain plug and drain off approx.

5.0 l (1.3 gal US) of fuel.

4. Collect the escaping fuel.

5. Screw the drain plug back on tightly.

6. Fill the fuel tank with clean fuel.

7. Dispose of collected fuel in line with environmental regula-

tions.

8.8.8 Checking radiator hoses and hose clamps

Protective equipment:

n

Working clothes

n

Protective gloves

1.

Park the machine in secured condition

Ä

Chapter 6.5

„Parking the machine in secured condition“ on page 90.

2. Allow the engine to cool down.

3. Check the condition and tight fit of all fuel lines and hose

clamps.

Fig. 157

Fig. 158

Maintenance – Every 250 operating hours/annually

D.ONE

124

Loading...

Loading...