Maintenance 7. Verifying Robot System Operation

RC180 Rev.17

7. Verifying Robot System Operation

When maintenance has been performed for either the Manipulator or the Controller,

including replacing any parts in those units, items must be checked according to the

procedures in this section to ensure proper operation.

(1) Connect all the necessary cables for the system.

WARNING

■

When verifying the robot system operation, prepare for failures with initial settings

or wiring. If the Manipulator operates abnormally because of incorrect initial

settings or wiring, press the Emergency Stop switch immediately to stop the

Manipulator.

Verify the robot system operation in the restricted mode (low speeds and low

power) status. Verifying the robot system operation at high speeds may damage

the robot system and/or cause serious safety problems as the Manipulator cannot

stop operating immediately in case of abnormal operation of the Manipulator.

The serial number of the Manipulator that should be connected is indicated on

the

Connection Check Label on the Controller. Connect the Controller and the

per connection between the Controller and the

Manipulator may cause not only improper function of the robot system but also

serious safety problems.

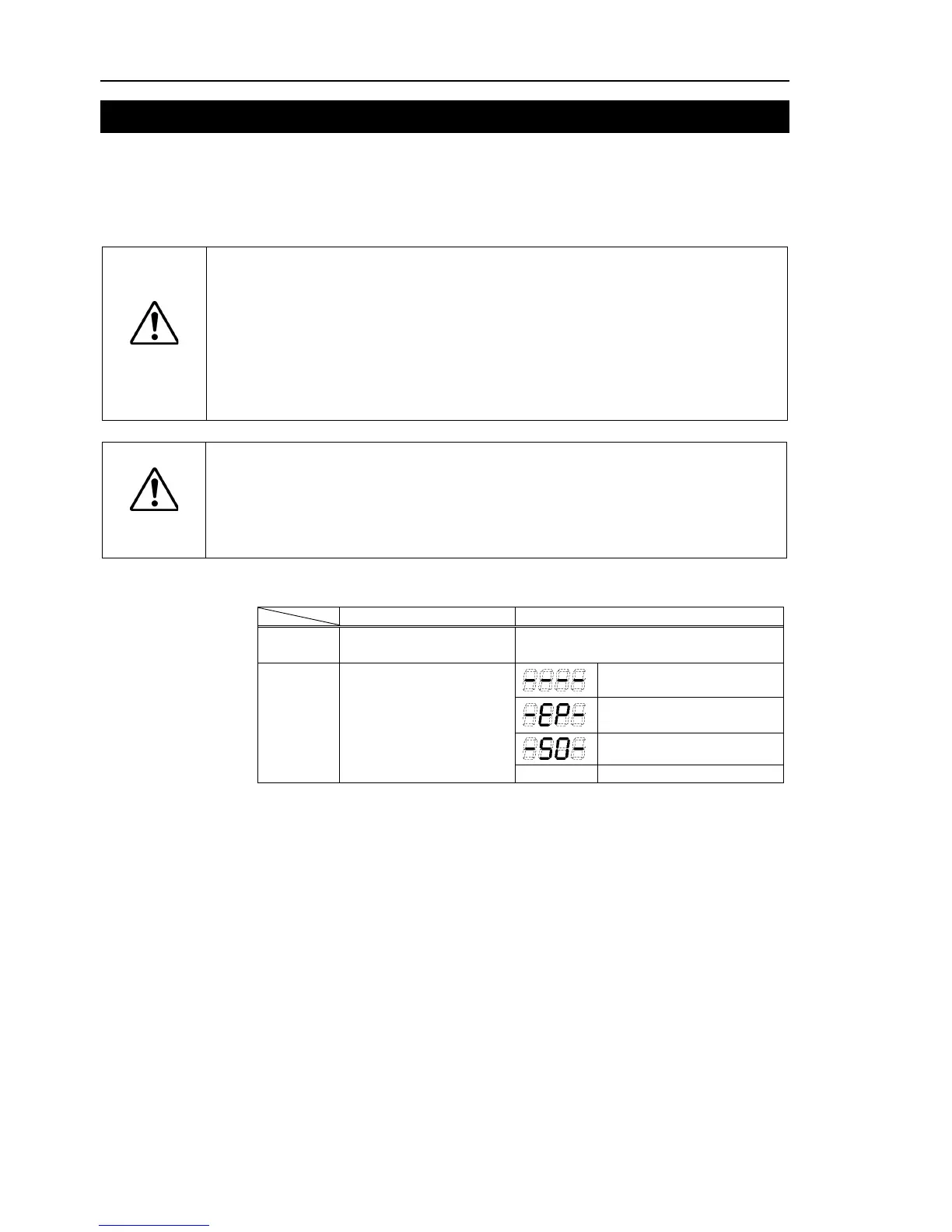

(2) Turn ON the Controller. The Controller will boot up. During this process, watch

and monitor the LED status as described in the following list:

LED for current operation mode

(TEACH, AUTO, PROGRAM) turns ON.

7 segment All lights out

READY (Normal)

Emergency Stop

For details of the display, refer to Maintenance 2.3 LED and Seven-segment LED.

For error number, refer to Maintenance 8.1 Error Code Table.

(3) Execute MOTOR ON and check the following:

- No error is displayed.

- There is servo excitation and the Manipulator operates normally.

(4) Execute various motion commands (such as JUMP, etc.). The Manipulator must

operate accordingly and normally without vibration or unusual sounds.

Loading...

Loading...