Setup & Operation 1. Specifications

10 RC180 Rev.17

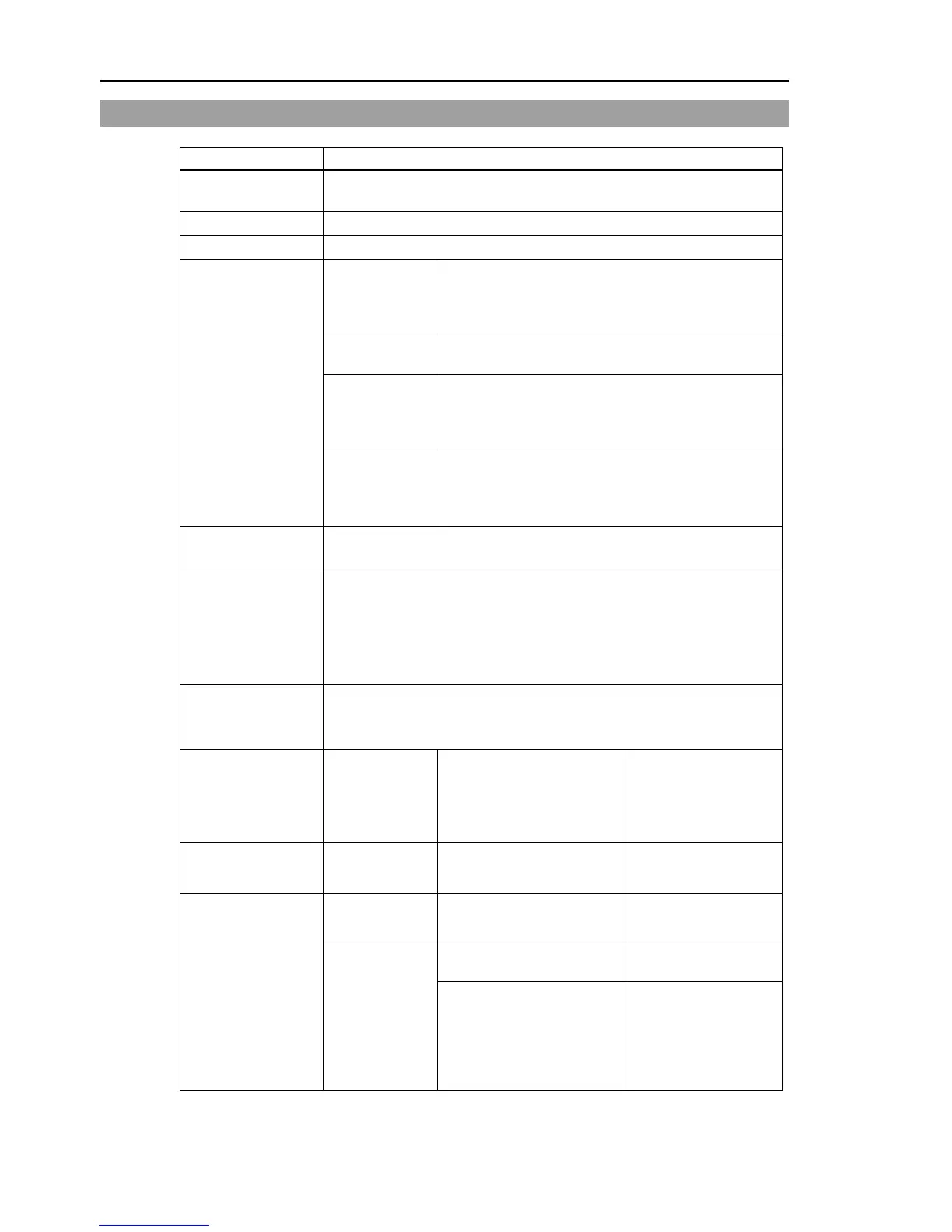

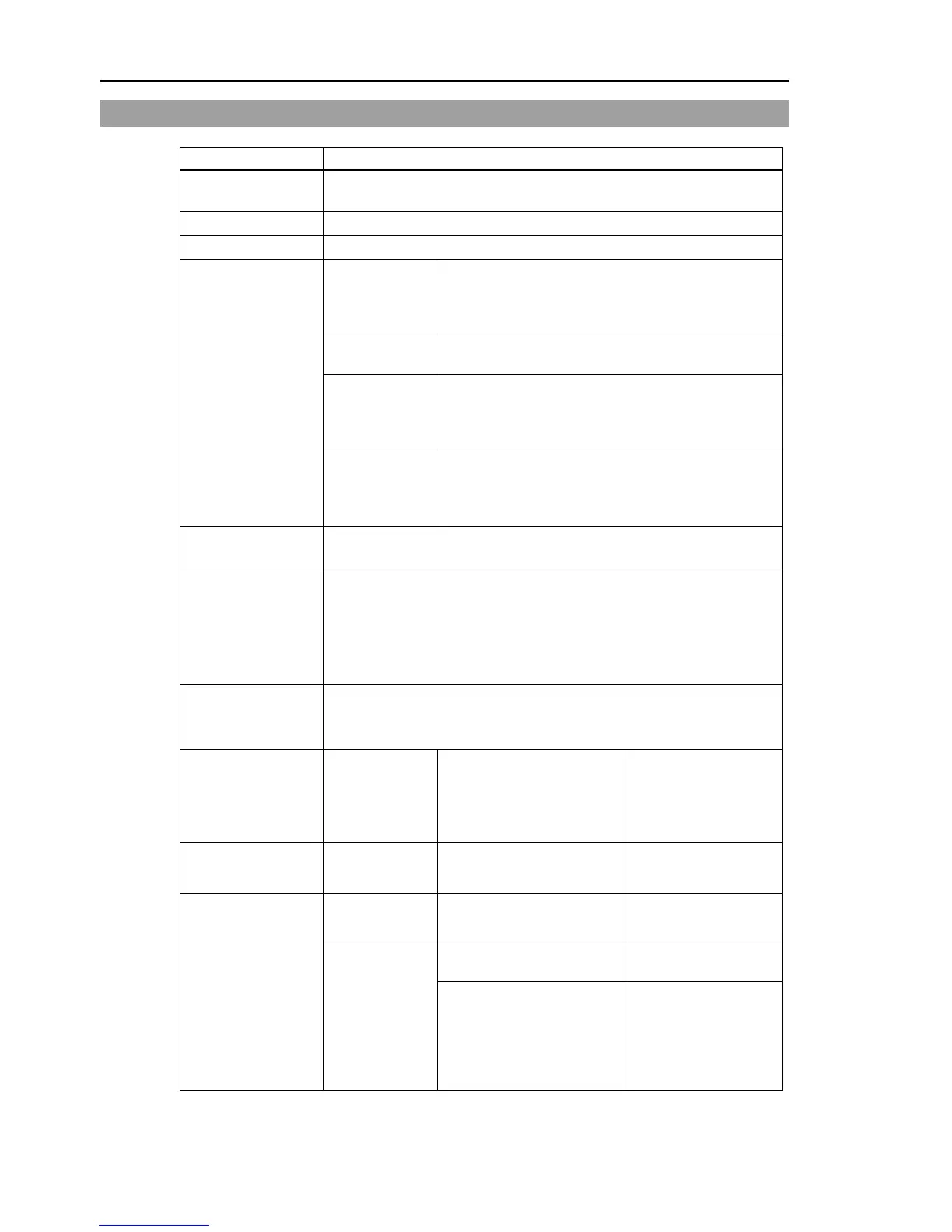

1.2 Standard Specifications

Robot Controller RC180

(UL specification: RC180-UL)

CPU 32 bits Ultra Low Voltage Processor

Controllable axes Up to six (6) connectable AC servo motors

Robot manipulator

control

language and

Robot control

software

EPSON RC+ 5.0

(a multi-tasking robot language)

Joint Control

Up to six (6) joints Simultaneous control

Software AC servo control

PTP motion : Programmable in the range of

1 to 100%

CP motion : Programmable (Actual value

Acceleration/

deceleration

control

PTP motion : Programmable in the range of

1 to 100%; Automatic

CP motion : Programmable (Actual value

Positioning control

PTP (Point-To-Point control)

CP (Continuous Path control)

Memory capacity

Maximum Object Size : 4 MB

Point data area : 1000 points (per file)

Backup variable area : Max. 100 k

B (Includes the memory area for

Approx. 1000 variables (Depends on the size

of array variables.)

Teaching method

Remote

Direct

MDI (Manual Data Input)

External

input/output

signals (standard)

Standard I/O

Input : 24

Output : 16

Including 8 inputs,

8 outputs with remote

function assigned

Assignment change

Communication

interface (standard)

Ethernet 1 channel

Options

(Max. 4 slots)

I/O

Input : 32 per board

Output : 32 per board

Addition of

Communication

interface

RS-232C : 4ch per board

Addition of

Fieldbus I/O : 1ch per board

PROFINET

PROFIBUS-DP

DeviceNet

CC-Link

Addition of

1 board allowed

Loading...

Loading...