SC-F2000 Revision C

ADJUSTMENT Overview 198

Confidential

[Blue]: Button or menu name on the program screen / [Black]: Button or menu name on the operation panel of the printer

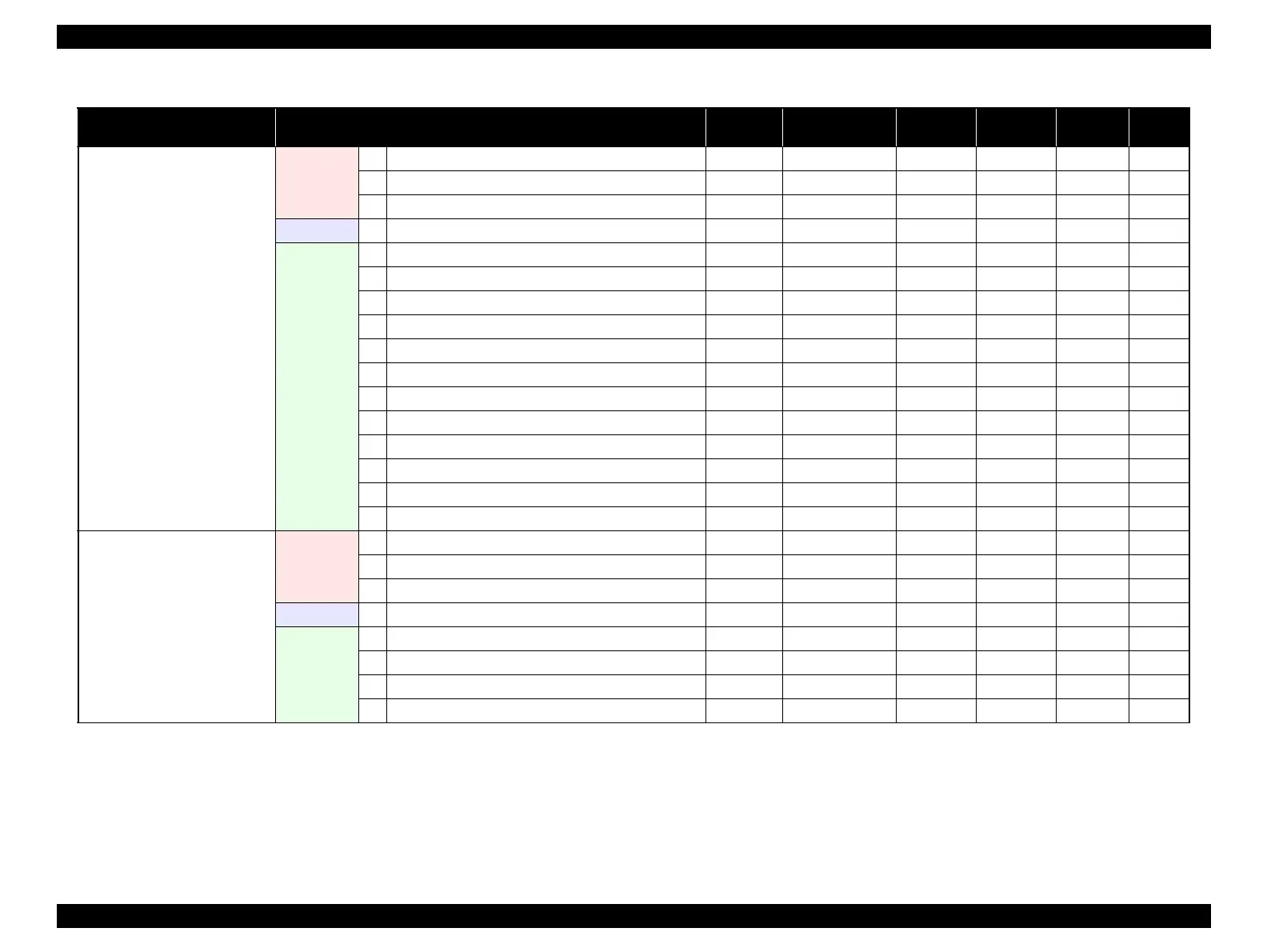

CR Unit

Before

replacement

1 PG Check

√

Thickness gauge

√√

p. 246

2 Turn the power on in Serviceman mode.

---

√√

3 Tube inner pressure reduction

√√√

p. 234

Replacement 4 Replace with a new one.

---

√√

p. 138

After

replacement

5 Turn the power on in normal mode. ---

√√

6 CR Belt tension adjustment

√

Tensimeter U-507

√√

p. 224

7 CR scale check

√√√

p. 226

8 PG Check/PG Adjustment

√

Thickness gauge

√√

p. 246

9CL3

√√√

p. 238

10 Nozzle Check & Cleaning

√

PGPP

√√

p. 237

11 Head inclination adjustment

√

PGPP

√√

p. 239

12 Head slant adjustment

√

PGPP

√√

p. 243

13 PG Check/PG Adjustment

√

Thickness gauge

√√

p. 246

14 Manual Uni-d adjustment

√

PGPP

√√

p. 227

15 Manual Bi-d adjustment

√

PGPP

√√

p. 229

16 1st dot positioning adjustment

√

PGPP

√√

p. 231

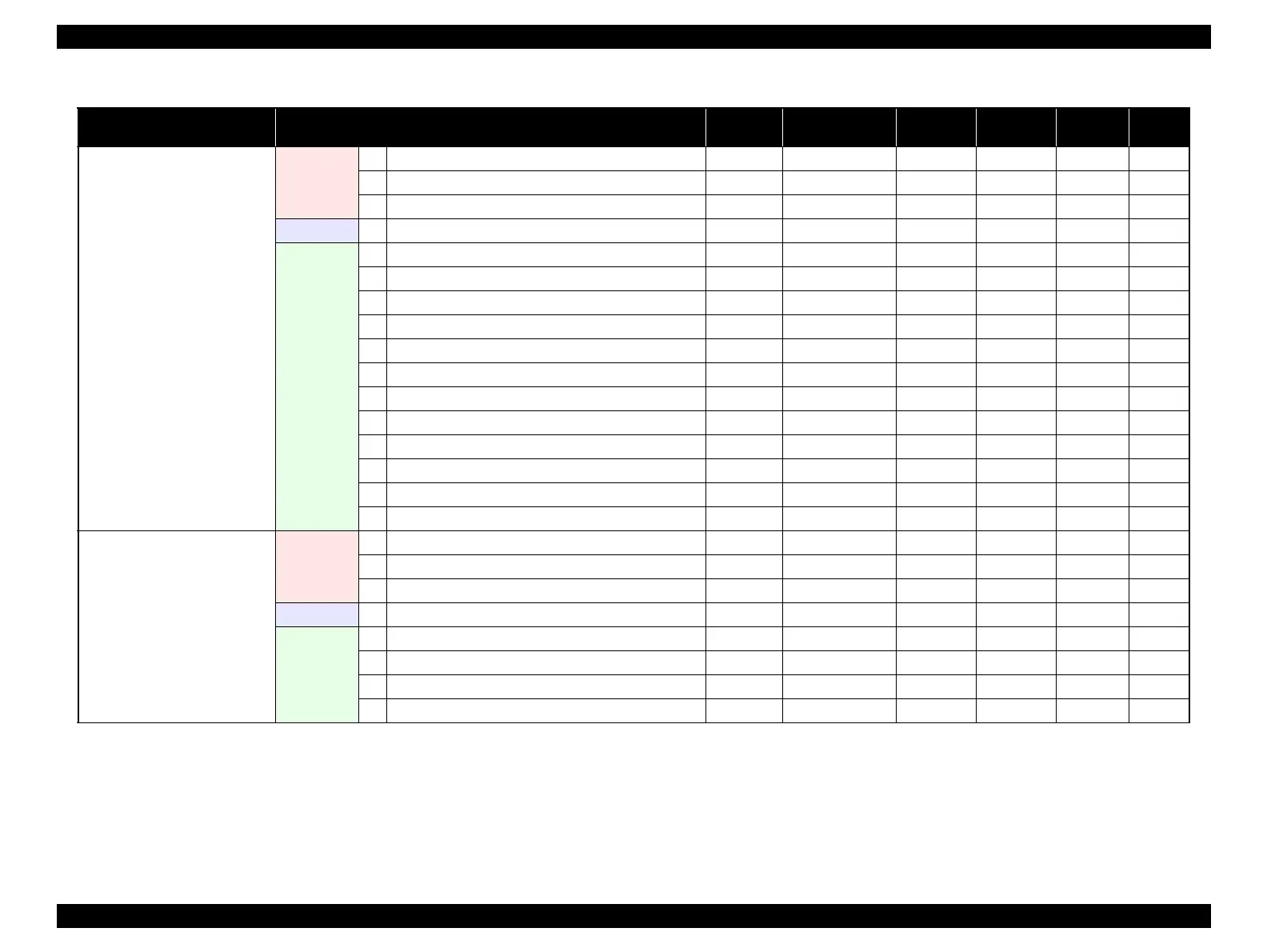

TF Motor Assy

Before

replacement

1 Turn the power on in Serviceman mode.

---

√

2 Counter Reset

√√

p. 221

3 Turn the power off.

---

√

Replacement 4 Replace with a new one.

---

√√

p. 185

After

replacement

5 Turn the power on in normal mode.

---

√√

6 TF Belt Tension Check √ Tensimeter U-507

√√

p. 253

7 TF Timing Belt tension adjustment

√

Tensimeter U-507

√

√ p. 255

8 TF Motor measurement

√√√

p. 282

Table 4-1. Adjustment Items and the Order by Repaired Part

Replaced or Repaired

(Reattached) Part/Unit

Required Operations

Service

Program

Jig Media Replaced Reattached Page

Loading...

Loading...