4.1 Test Run

4-10

Tuning procedure

(1) Selection of tuning type

Check the situation of the machinery and select "Tuning with the motor stopped (P04

*

= 1)" or "Tuning with

the motor running (P04

*

= 2)." For the latter tuning, adjust the acceleration and deceleration times (F07 and

F08) and specify the rotation direction that matches the actual rotation direction of the machinery.

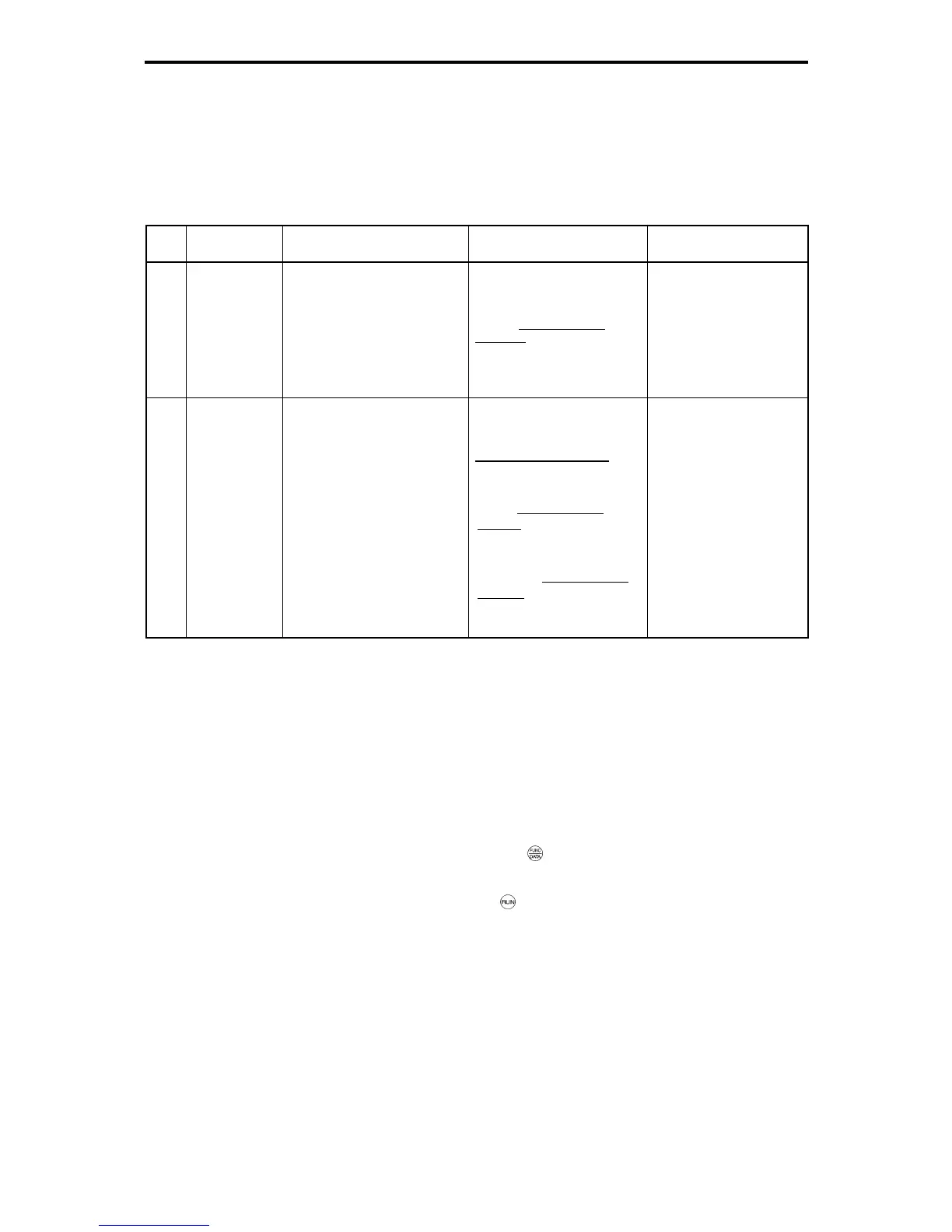

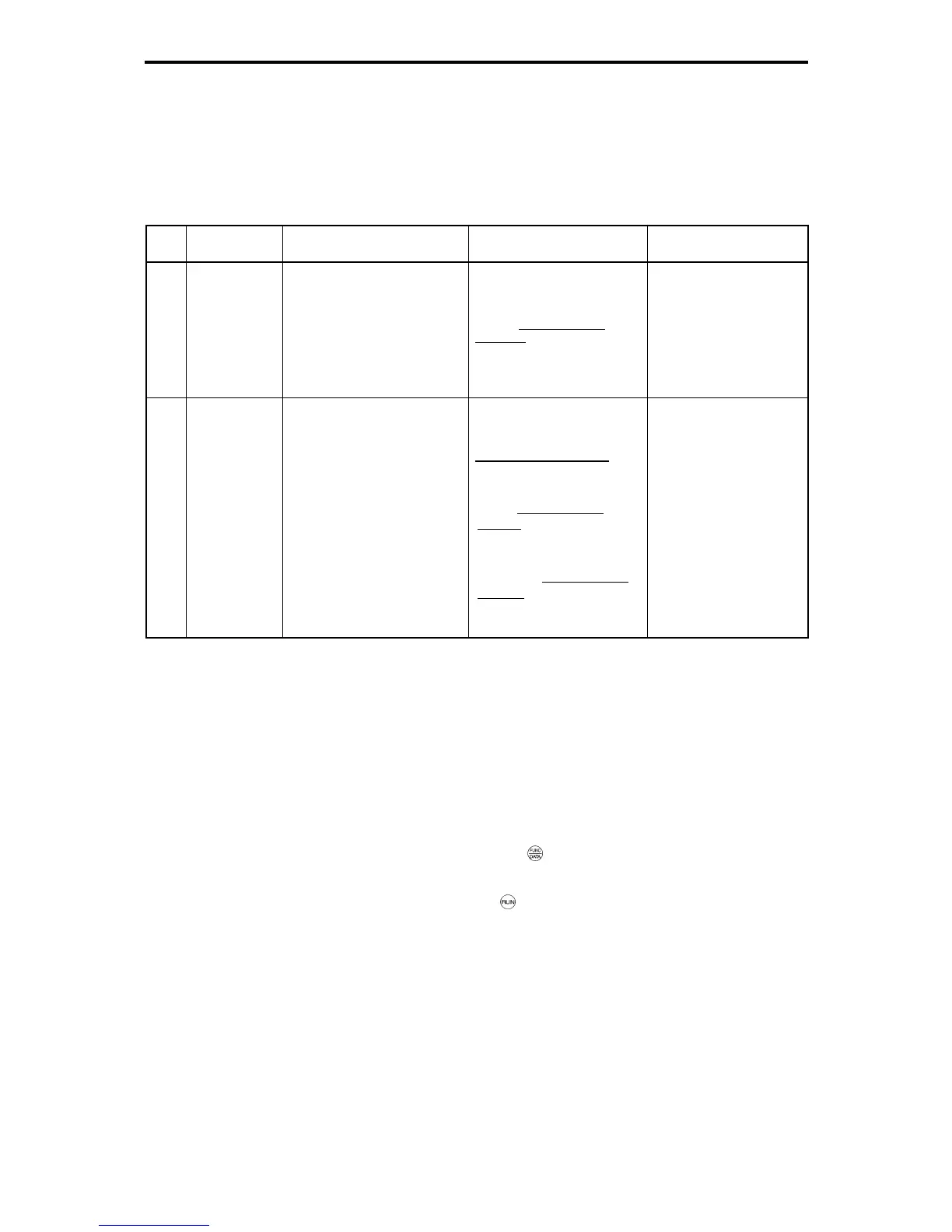

Table 4.1-8

P04

*

data

Tuning

type

Motor parameters subject

to tuning

Tuning

Select under the

following conditions

1

Tune while the

motor stops.

Primary resistance (%R1)

(P07

*

)

Leakage reactance (%X)

(P08

*

)

Rated slip frequency (P12

*

)

%X correction factor 1 and 2

(P53

*

and P54

*

)

Tuning with the motor

stopped.

Cannot rotate the motor.

2

Tune while the

motor is

rotating under

V/f control

No-load current (P06

*

)

Primary resistance (%R1)

(P07

*

)

Leakage reactance (%X)

(P08

*

)

Rated slip frequency (P12

*

)

Magnetic saturation factor 1 -

5

Extended magnetic

saturation factor a - c

(P16

*

- P23

*)

%X correction factor 1 and 2

(P53

*

and P54

*

)

Tuning the %R1 and %X,

with the motor stopped

.

Tuning the no-load current

and magnetic saturation

factor, with the motor

running at 50% of the base

frequency.

Tuning again the rated slip

frequency, with the motor

stopped.

Can rotate the motor,

provided that it is safe.

Note that little load

should be applied during

tuning. Tuning with load

applied decreases the

tuning accuracy.

The tuning results of motor parameters will be automatically saved into their respective function codes.

If P04

*

tuning is performed, for instance, the tuning results will be saved into P

*

codes (Motor 1

*

parameters).

(2) Preparation of machinery

Perform appropriate preparations on the motor and its load, such as disengaging the coupling from the

motor and deactivating the safety devices.

(3) Tuning procedure

1) Set function code P04

*

to "1" or "2" and press the

key. (The blinking of

1

or

2

on the LED

monitor will slow down.)

2) Enter a run command. (The factory default is

key on the keypad for forward rotation. To switch

to reverse rotation or to select the terminal signal FWD or REV as a run command, change the data

of function code F02.)

3) The moment a run command is entered, the display of

1

or

2

lights up, and tuning starts with the

motor stopped.

(Maximum tuning time: Approx. 40 to 80 s.)

4) If P04

*

= 2, after the tuning in 3) above, the motor is accelerated to approximately 50% of the base

frequency and then tuning starts. Upon completion of measurements, the motor decelerates to a

stop.

(Estimated tuning time: Acceleration time + 20 to 75 s + Deceleration time)

5) If P04

*

= 2, after the motor decelerates to a stop in 4) above, tuning continues with the motor

stopped.

Loading...

Loading...