10.1 Selecting Motors and Inverters

10-7

Chapter 10 SELECTING OPTIMAL MOTOR AND INVERTER CAPACITIES

10.1.3 Equations for selections

[1] Load torque during constant speed running

[1] General equation

The frictional force acting on a horizontally moved load must be calculated. Calculation for driving a load

along a straight line with the motor is shown below.

Where the force to move a load linearly at constant speed υ (m/s) is F (N) and the motor speed for driving

this is N

M

(r/min), the required motor output torque τ

M

(N·m) is as follows:

60 • υ F

τ

M

=

2π • N

M

•

η

G

(N • m) (10.1)

where, η

G

is Reduction-gear efficiency.

When the inverter brakes the motor, efficiency works inversely, so the required motor torque τ

M

(N • m)

should be calculated as follows:

60 • υ

τ

M

=

2π • N

M

• F • η

G

(N • m) (10.2)

(60·υ) / (2π· N

M

) in the above equation is an equivalent turning radius corresponding to speedυ (m/s)

around the motor shaft.

The value F (N) in the above equations depends on the load type.

[2] Obtaining the required force F

Moving a load horizontally

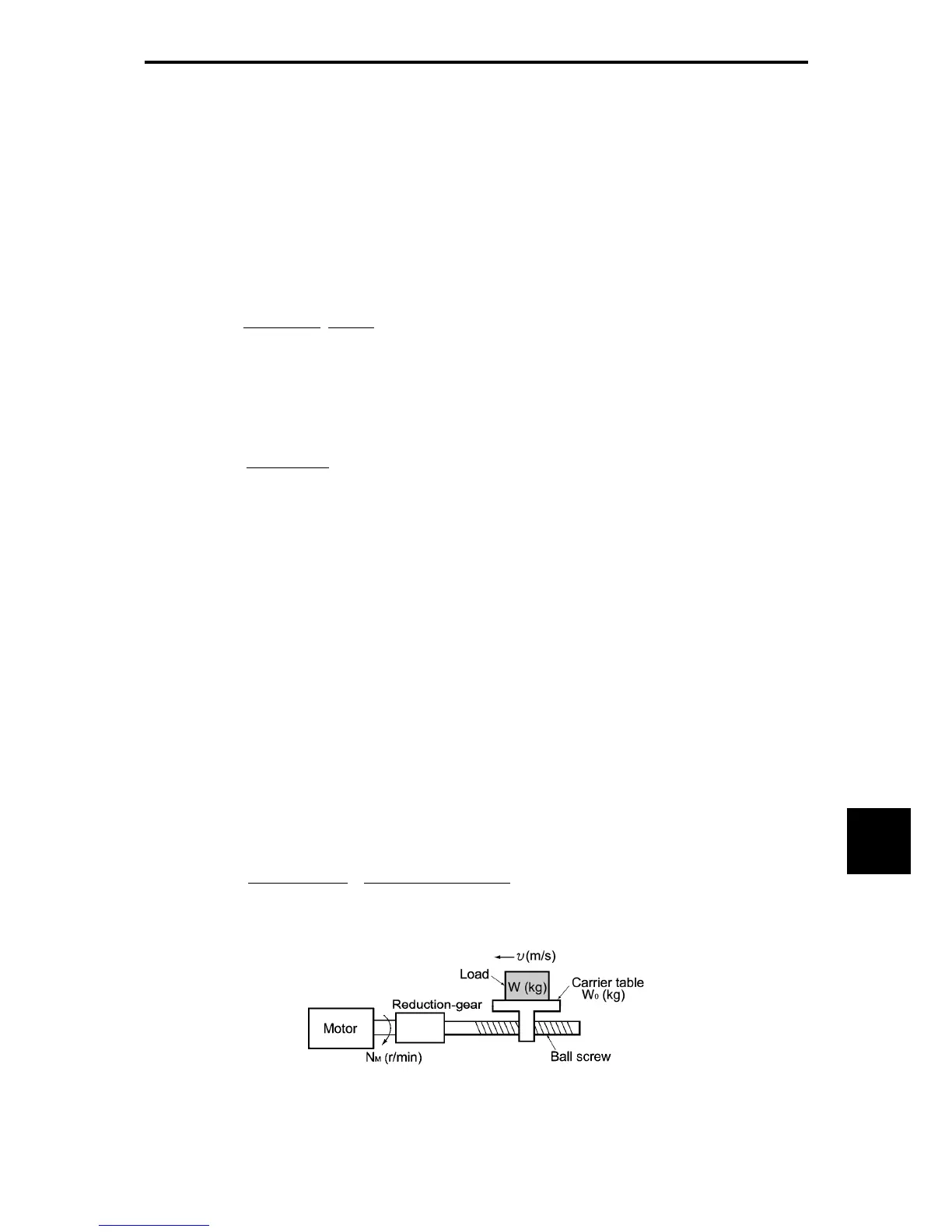

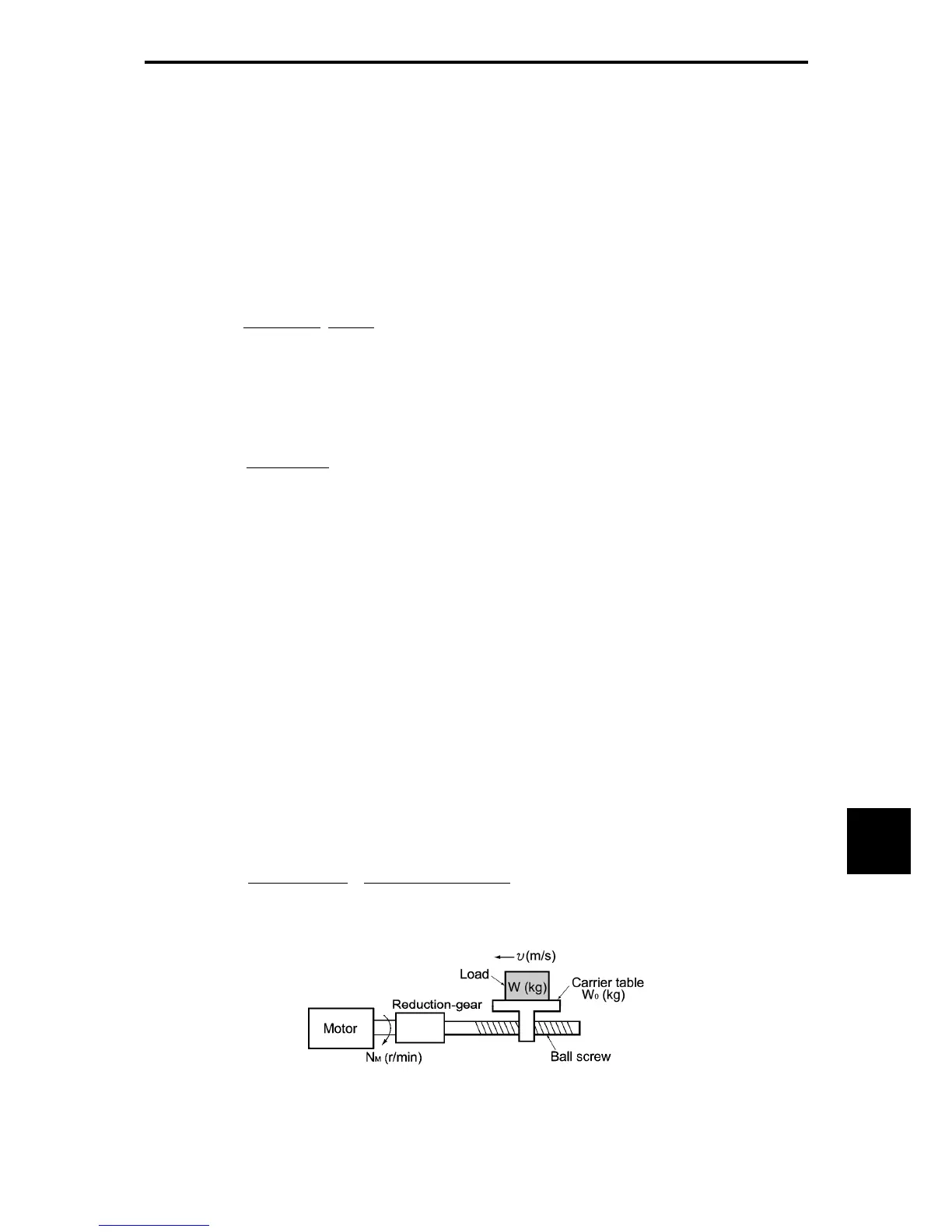

A simplified mechanical configuration is assumed as shown in Figure 10.1-7. If the mass of the carrier

table is W

0

(kg), the load is W (kg), and the friction coefficient of the ball screw is μ, then the friction force F

(N) is expressed as follows, which is equal to a required force for driving the load:

F = (W

0

+ W) • g • μ (N) (10.3)

where, g is the gravity acceleration (≈ 9.8 (m/s

2

)).

Then, the driving torque around the motor shaft is expressed as follows:

Figure 10.1-7 Moving a Load Horizontally

60 • υ (W

O

+ W) • g • μ

τ

M

=

2π • N

M

•

η

G

(N • m) (10.4)

Loading...

Loading...