5.4 Details of Function Codes

5-203

Details of

Function Codes

F codes

E codes

C codes

P codes

H78 to H82

A codes

b codes

r codes

J codes

d codes

U codes

y codes

Chapter 5 Function Code

H81, H82

Light Alarm Selection 1 and 2

If the inverter detects a minor abnormal state, it can continue the current operation without tripping while

displaying the "light alarm" indication

l-al

on the LED monitor. In addition to the indication

l-al

, the

inverter blinks the KEYPAD CONTROL LED. Function codes H81 and H82 specify which alarms should be

categorized as "light alarm."

The table below lists alarms selectable as "light alarm."

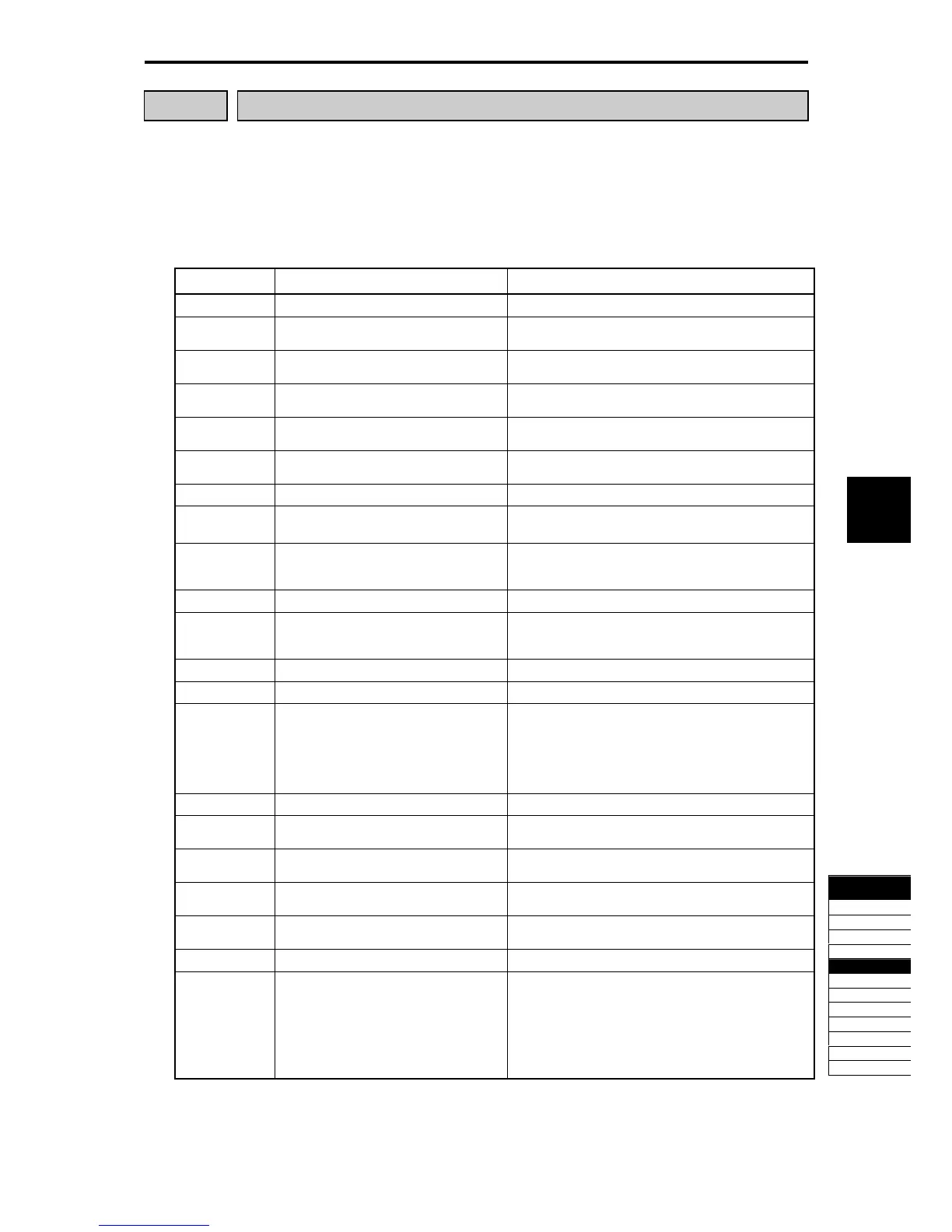

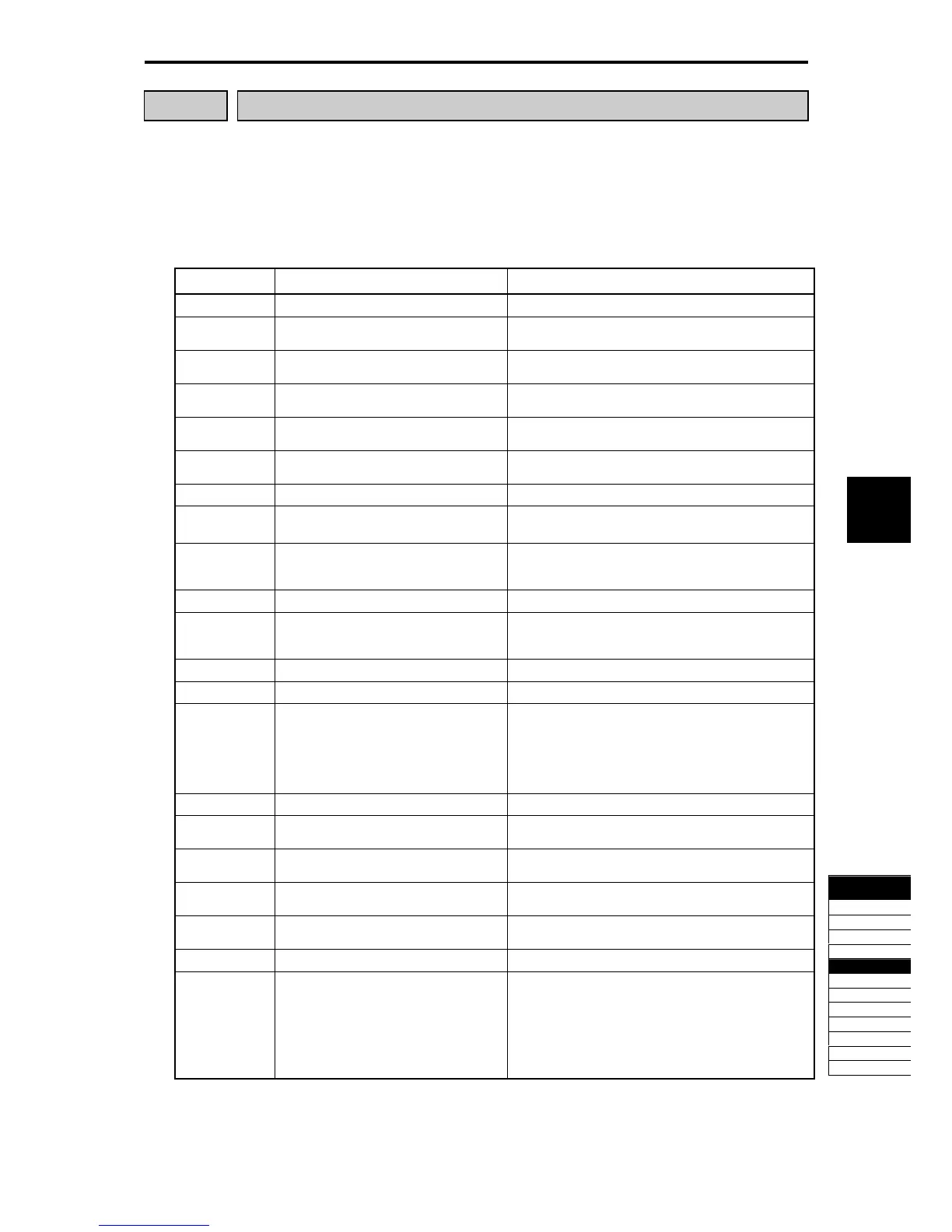

Table 5.4-137

Code Name Overview

0h1

Cooling fin overheat Cooling fin temperature increased to the trip level.

0h2

External alarm

An error occurs in peripheral equipment, and external

alarm THR signal turns on.

0h3

Inverter internal overheat

The temperature inside the inverter abnormally has

increased.

dbh

Braking resistor overheat

Estimated temperature of the coil in the braking resistor

exceeded the allowable level.

0l1

to

0l4

Overload of motor 1 through 4

Motor temperature calculated with the inverter output

current reached the trip level.

er4

Option communications error (detection)

Communications error between the inverter and an

option.

er5

Option error An option judged that an error occurred.

er8

erp

RS-485 communication error

(Communication port 1, 2)

RS-485 communications error between the COM ports 1 and

2.

ere

Speed mismatch or excessive speed

deviation

The deviation of the speed controller (speed command

and detected speed) is out of the set range (d21) for a

period longer than the set time (d22).

cof

PID feedback wire break detection The PID feedback signal wire is broken.

fal

DC fan lock detection

Failure of the air circulation DC fan inside the inverter.

(200 V class: 45 kW or above. 400 V class: 75 kW or

above.)

0l

Motor overload early warning Early warning before a motor overload alarm output

0h

Cooling fin overheat warning Early warning before a cooling fin overheat trip

lif

Lifetime warning

It was judged that the service life of either one of main

circuit capacitor, electrolytic capacitor of printed board,

and cooling fan has expired.

Or, failure of the air circulation DC fan inside the

inverter. (200 V class: 45 kW or above. 400 V class: 75

kW or above.)

ref

Command loss Analog frequency command was broken.

pid

PID alarm output

Warning related to PID control (absolute-value alarm or

deviation alarm)

uTl

Low torque detection

Output torque drops below the low torque detection

level for the specified period.

pTc

Thermistor detection (PTC)

The PTC thermistor on the motor detected a

temperature.

rTe

Machinery life (Motor cumulative run

time)

The motor cumulative run time reached the

maintenance time set by the motor cumulative run time.

cnT

Machinery life (Number of startups) Number of startups reached the specified level.

ero

Positioning deviation over

When the second bit of H82 is set to 1, the excessive

position deviation in simultaneous operation is set to an

objective of light alarm.

For details of the position deviation over, see the PG

interface card instruction manual.

Note: The excessive position deviation in the servo lock

cannot be set to light alarm object.

Set data for selecting "light alarms" in hexadecimal. For details on how to select the codes, see the next

page.

- Data setting range: 0000 to FFFF (in Hex.)

Loading...

Loading...