11.4 Option

11-34

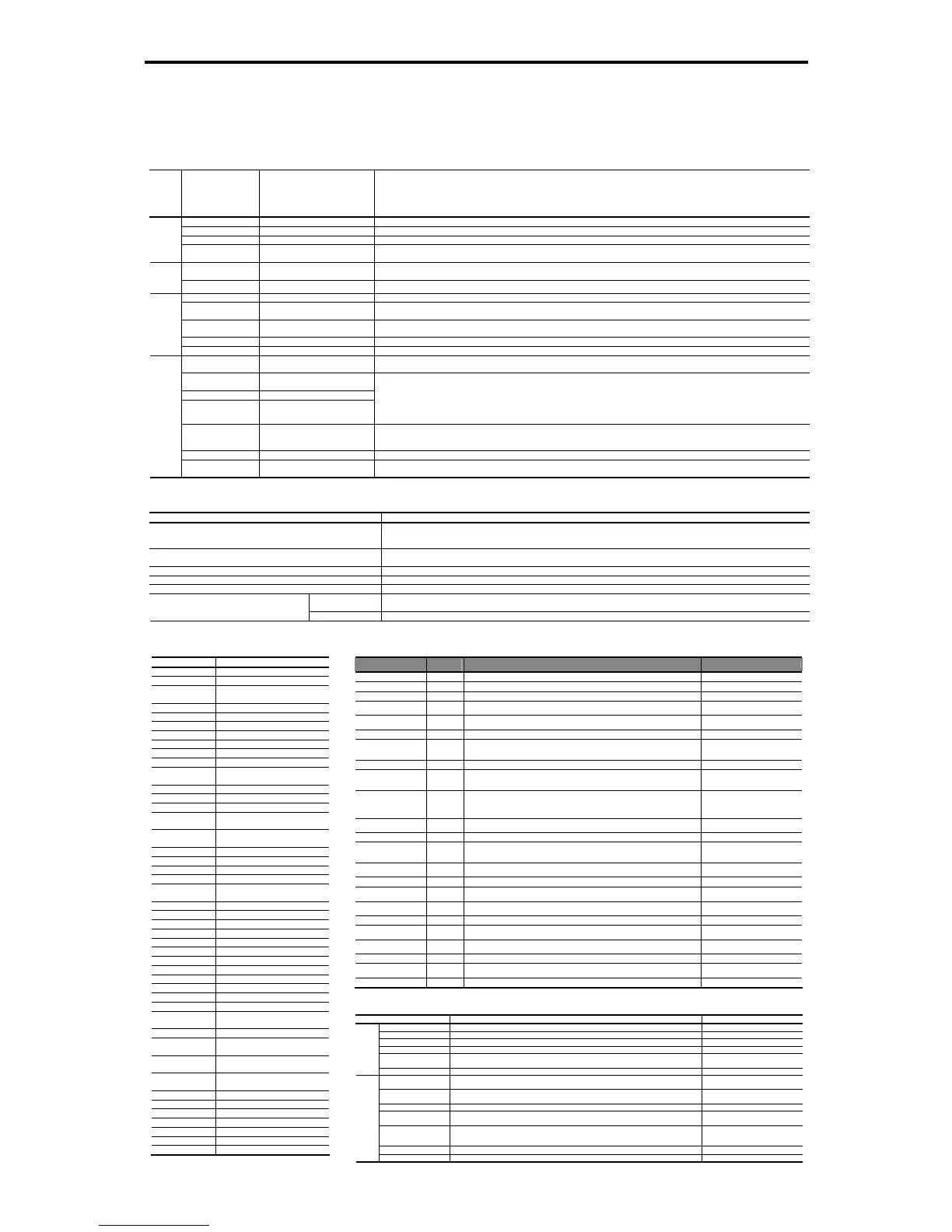

(3) Function specifications

Table 11.4-9

Terminal functions

Classification

Symbol Name Functions

L1/R, L2/S, L3/T Main circuit power inputs Connects with the three-phase input power lines through a dedicated reactor.

P(+), N(-) Converter outputs Connects with the power input terminals P(+) and N(-) on an inverter.

ok Grounding Grounding terminal for the converter's chassis (or casing).

Main circuit

R0, T0

Auxiliary power input for the

control circuit

For a backup of the control circuit power supply, connect the power lines same as that of the main power input.

R1, S1, T1

Synchronous power input for

voltage detection

Voltage detection terminals for the internal control of the converter. Connect with the power supply side of the dedicated reactor or

filter.

Voltage

detection

R2, T2 Inputs for control monitoring Detection terminal for AC fuse blown.

[RUN] Run command Short-circuiting terminals [RUN] and [CM] runs the converter; opening them stops the converter.

[RST] Reset alarm command

When the converter stops due to an alarm, removing the alarm factor and short-circuiting the terminals [RST] and [CM] cancels the

protective function, restarting the converter.

[X1] General-purpose transistor input

0: Enable external alarm trip THR 1: Cancel current limiter LMT-CCL 2: 73 answerback 73ANS 3: Switch current limiter I-LIM

4: Option DI OPT-DI

[CM] Digital input common Common terminal for digital input signals.

Input signal

[PLC] PLC signal power Connects to PLC output signal power supply. (Rated voltage: 24 VDC (22 to 27 VDC)

[30A/B/C]

Alarm relay output

(for any alarm)

Outputs a signal when the protective function is activated to stop the converter.

(Contact: [1C], Terminals [30A] and [30C] are closed: Signal ON) (Contact rating: 250 VAC, max. 50 mA)

[Y1], [Y2], [Y3], [Y11]

to [Y18]

General-purpose transistor output

[CME] Digital output common

[Y5A/C] Relay output

0: Converter running RUN 1: Converter ready to run RDY 2: Power supply current limiting IL 3: Lifetime alarm LIFE

4: Heat sink overheat early warning PRE-OH 5: Overload early warning PRE-OL 6: Power running DRV 7: Regenerating REG

8: Current limiting early warning CUR 9: Restarting after momentary power failure U-RES

10: Synchronizing power supply frequency SY-HZ 11: Alarm content 1 AL1 12: Alarm content 2 AL2 13: Alarm content 4 AL4

14: Option DO OPT-DO

* Mounting the OPC-VG7-DIOA option makes 8 points of DO extended functions available. (DI functions are not available.)

[A01], [A04], [A05] General-purpose analog output

0: Input power PWR 1: Input current in RMS I-AC 2: Input voltage in RMS V-AC 3: DC link bus voltage V-DC

4: Power supply frequency FREQ 5: +10 V test P10 6: -10 V test N10

* Mounting the OPC-VG7-AIO option makes 2 points of AO extended functions available. (AI functions are not available.)

[M] Analog output common Common terminal for analog output signal.

Output signal

[73A], [73C]

Charging resistor input relay

outputs

Control output for the input relay of the external charging resistor (73).

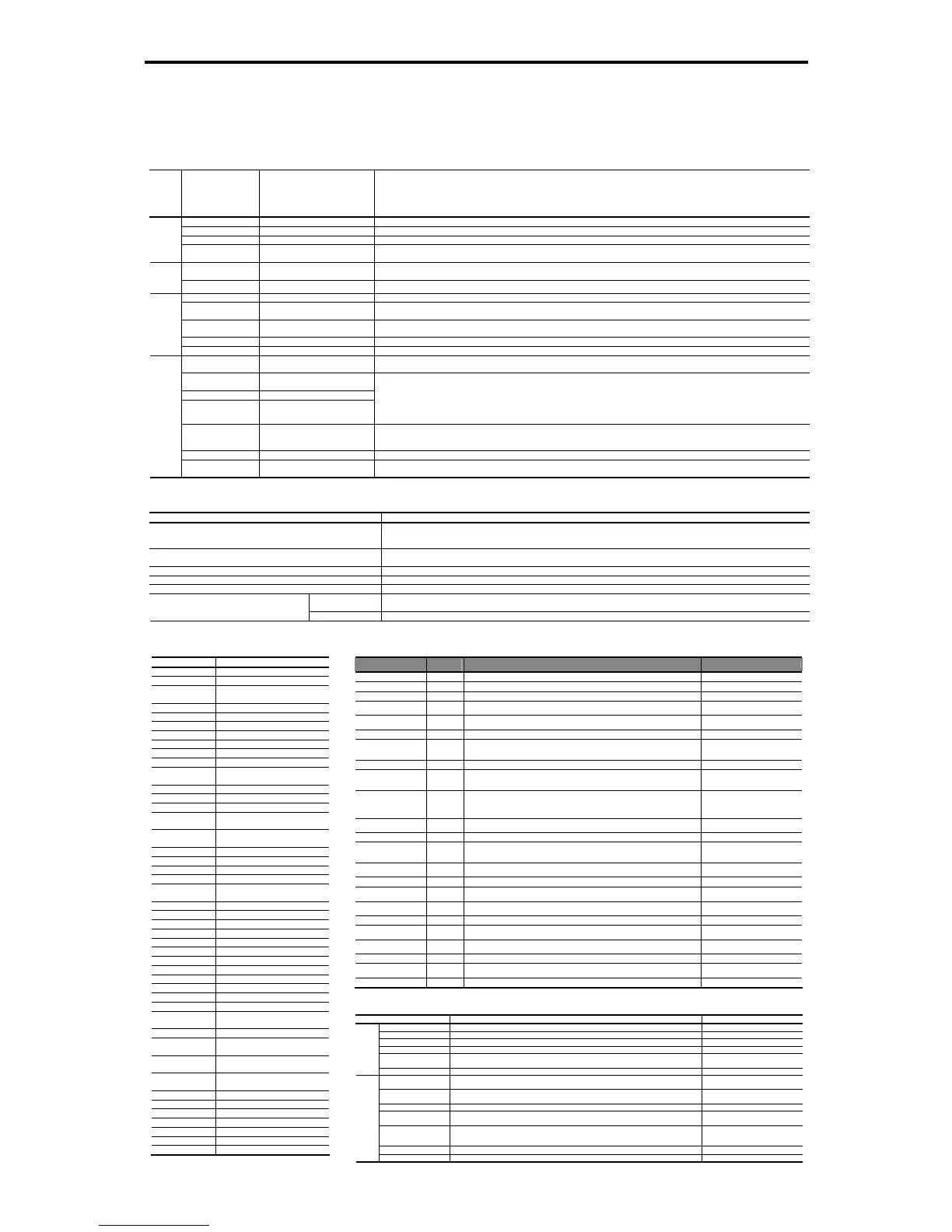

Communications specifications

Item Specifications

General communication specifications

Monitoring the running information, running status and function code data, and controlling (selecting) the terminals [RUN], [RST]

and [X1].

* Writing to function codes is not possible.

RS-485 (standard)

Communicating with a PC or PLC.

(The converter supports the Fuji general-purpose inverter protocol and Modbus RTU protocol.)

T-Link (option) Mounting the OPC-VG7-TL option enables communication with a T-Link module of MICREX-F or MICREX-SX via a T-Link network.

SX-bus (option) Mounting the OPC-VG7-SX option enables communication with a MICREX-SX via an SX bus network.

CC-Link (option) Mounting the OPC-VG7-CCL option enables communication with a CC-Link master.

Hardware Mounting the OPC-RHC-TR option enables tracing back of the running status data of the converter.

WPS-LD-TR software is required.

Traceback (option)

Software Installing the WPS-RHC-TR software enables collecting of traceback data on the PC.

Function settings

Function code Name

F00 Data protection

F01 High frequency filter selection

F02 Restart mode after momentary

power failure (Mode selection)

F03 Current rating switching

F04 LED monitor, item selection

F05 LCD monitor, item selection

F06 LCD monitor, language selection

F07 LCD monitor, contrast control

F08 Carrier frequency

E01 Terminal [X1] function

E02 to E13 Terminal [Y1], [Y2], [Y3,], [Y5],

[Y11] to [Y18] function

E14 I/O function normal open/closed

E15 RHC overload early warning level

E16 Cooling fan ON/OFF control

E17 Under current limiting (Hysteresis

width)

E18 to E20 A01, A04 and A05, function

selection

E21 to E23 A01, A04 and A05, gain setting

E24 to E26 A01, A04 and A05, bias setting

E27 A01, A04 and A05, filter setting

S01 Operation method

S02, S03 Power supply current limiting

(driving/braking)

H01 Station address

H02 Communications error processing

H03 Timer

H04 Baud rate

H05 Data length

H06 Parity bits

H07 Stop bits

H08 No-response error detection time

H09 Response interval

H10 Protocol selection

H11 TL transmission format

H12 Parallel system

H13 Number of slave stations in

parallel system

H14 Clear alarm data

H15, H16 Power supply current limiter

(driving 1/2)

H17, H18 Power supply current limiter

(braking 1/2)

H19, H20 Current limiting early warning

(level/timer)

M09 Power supply frequency

M10 Input power

M11 Input current in RMS

M12 Input voltage in RMS

M13 Run command

M14 Running status

M15 Output terminals [Y1] to [Y18]

Protective functions

Item

LED monitor

displays:

Description Remarks

AC fuse blown

acf

Stops the converter output if the AC fuse (R-/T-phase only) is blown.

AC overvoltage

a0u

Stops the converter output upon detection of an AC overvoltage condition.

AC undervoltage

alu

Stops the converter output upon detection of an AC undervoltage condition.

AC overcurrent

a0c

Stops the converter output if the peak value of the input current exceeds the overcurrent

level.

AC input current error

ace

Stops the converter output upon detection of the excessive deviation of the AC reactor

from the AC input.

Input phase loss

lpu

Stops the converter output upon detection of an input phase loss.

Synchronous power

frequency error

fre

After the MC for charging circuit (73) is turned on, the converter checks the power

frequency. If it detects a power frequency error, this function stops the converter output.

An error during converter running (e.g., momentary power failure) triggers no alarm.

DC fuse blown

dcf

Stops the converter output if the DC fuse (P side) is blown. 18.5 kW or above

DC overvoltage

d0u

Stops the converter output upon detection of a DC overvoltage condition.

If a power failure continues for a long time and the control power source is shut down, this

alarm is automatically reset.

200 V class series: 400 V ±3 V

400 V class series:800 V ±5 V

DC undervoltage

dlu

Stops the converter output upon detection of a DC undervoltage condition.

If a power failure continues for a long time and the control power source is shut down, this

alarm is automatically reset.

200 V class series: Stops at 185 V,

restarts at 208 V.

400 V class series: Stops at 371 V,

restarts at 417 V.

Charging circuit fault

pbf

Stops the converter output upon detection of a charging circuit fault, provided that the

answerback signal from 73 is enabled.

Condition: 73ANS (Answerback from

73) is assigned to terminal [X1].

Heat sink overheat

0h1

Stops the converter output upon detection of a heat sink overheat.

External alarm

0h2

Stops the converter output upon receipt of an external signal THR. Condition: THR (Enable external

alarm trip) is assigned to terminal

[X1].

Converter internal

overheat

0h3

Stops the converter output upon detection of an internal overheat of the converter.

Converter overload

0lu

Stops the converter output with the inverse-time characteristics due to the input current. Activate at 105%, 150% for 1 min

Memory error

er1

Stops the converter output if a data writing error or any other memory error occurs (when

the checksums of the EEPROM and RAM do not match).

Keypad communications

error

er2

Displays "er2 " upon detection of a wire break in initial communication with the keypad.

This does not affect the converter operation.

CPU error

er3

Activated if a CPU error occurs.

Network device error

er4

Stops the converter output if a fatal error (including no power supply connection) occurs in

the master unit in the network.

Applies to T-Link, SX-bus, and

CC-Link devices.

Operation procedure

error

er6

Stops the converter output upon detection of an error in the operation procedure.

A/D converter error

er8

Stops the converter output upon detection of a failure in the A/D converter circuit.

Optical network error

erb

Stops the converter output upon detection of an optical cable break or a fatal error in the

optical option.

IPM error

1pe

Activated when the IPM's self-diagnosis function works due to an overcurrent or overheat. 15 kW or below

Required structure and environment

Item Required structure, environment and standards Remarks

Structure Mounting in a panel or mounting for external cooling

Enclosure IP00

Cooling system Forced air cooling

Installation Vertical installation

Coating color Munsell 5Y3/0.5, eggshell

(Same color as our inverter FRENIC 5000VG7S series.)

Structure

Maintainability Structure designed for easy parts replacement

Site location Shall be free from corrosive gases, flammable gases, dusts, and direct sunlight. Indoor use

only.

Surrounding

temperature

-10 to 50°C

Relative humidity 5 to 95% RH (No condensation)

Altitude 3,000 m max. (For use in an altitude between 1,001 m to 3,000 m, the output current should

be derated.)

Vibration 2 to 9 Hz: Amplitude = 3 mm, 9 to 20 Hz: 9.8 m/s

2

,

20 to 55 Hz: 2 m/s

2

(9 to 55 Hz: 2 m/s

2

for 90 kW or above),

55 to 200 Hz: 1 m/s

2

Storage temperature

-20 to 55°C

Environment

Storage humidity 5 to 95% RH

Loading...

Loading...