4.1 Test Run

4-14

2) Enter a run command. (The factory default is key on the keypad for forward rotation. To switch to

reverse rotation or to select the terminal signal FWD or REV as a run command, change the data of

function code F02.)

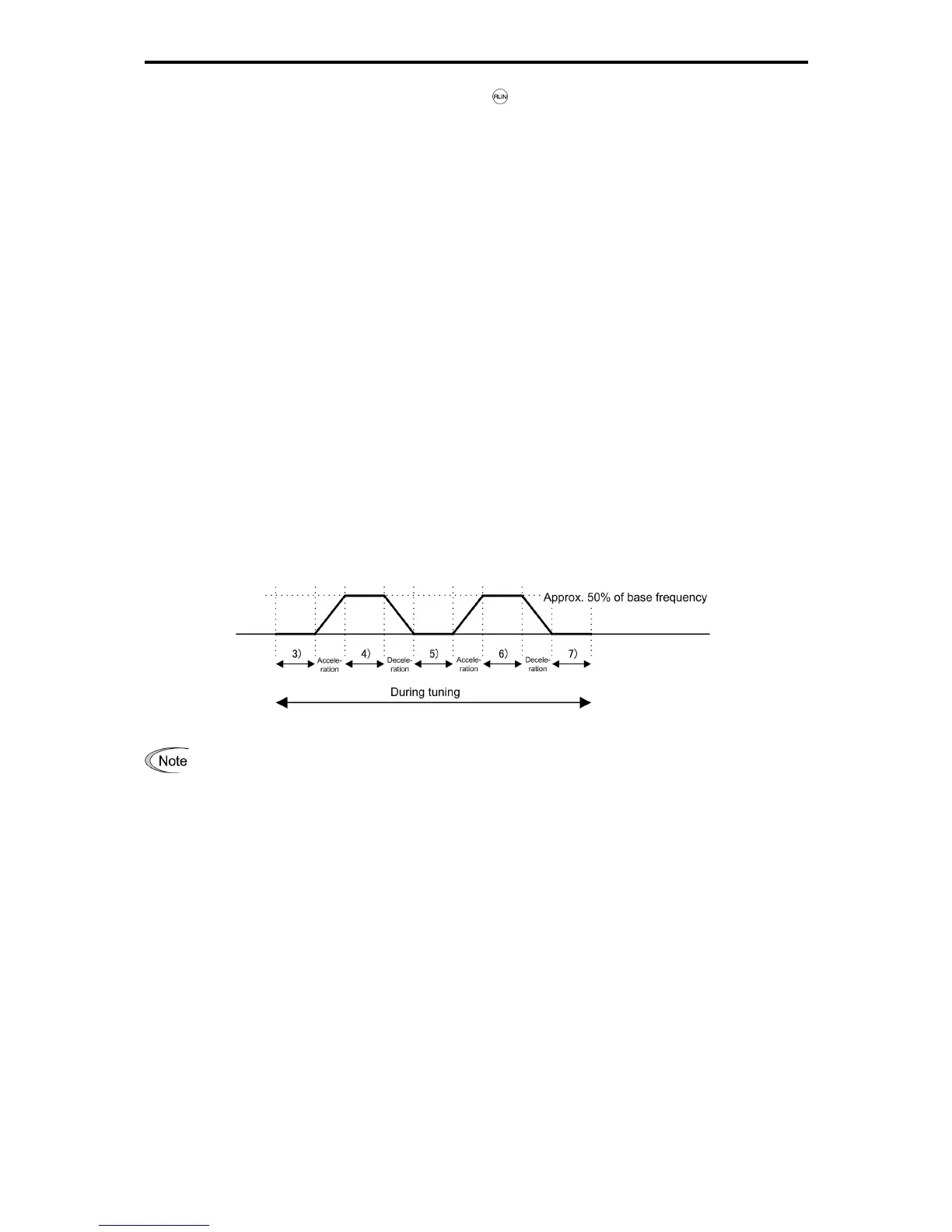

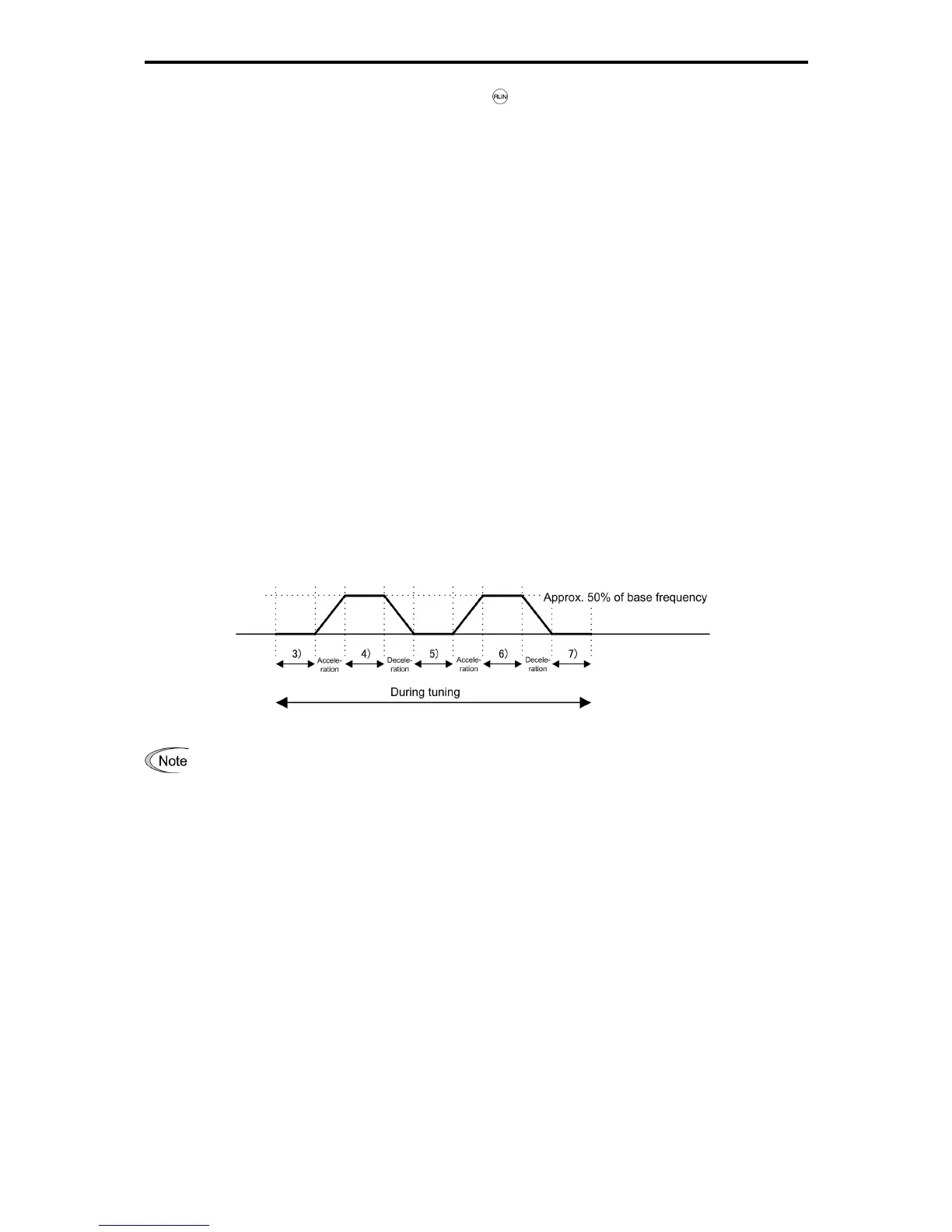

3) The moment a run command is entered, the display of

3

lights up, and tuning starts with the motor

stopped.

(Maximum tuning time: Approx. 40 to 75 s.)

4) The motor is accelerated to approximately 50% of the base frequency and then tuning starts. Upon

completion of measurements, the motor decelerates to a stop. (Estimated tuning time: Acceleration

time + 20 to 75 s + Deceleration time)

5) After the motor decelerates to a stop, tuning continues with the motor stopped.

(Maximum tuning time: Approx. 20 to 35 s.)

6) The motor is accelerated to approximately 50% of the base frequency again and then tuning starts.

Upon completion of measurements, the motor decelerates to a stop.

(Estimated tuning time: Acceleration time + 20 to 160 s + Deceleration time)

7) After the motor decelerates to a stop, tuning continues with the motor stopped.

(Maximum tuning time: Approx. 20 to 30 s.)

8) If the terminal signal FWD or REV is selected as a run command (F02 = 1),

end

appears upon

completion of the measurements. Turning the run command OFF completes the tuning.

If the run command has been given through the keypad or the communications link, it automatically

turns OFF upon completion of the measurements, which completes the tuning.

9) Upon completion of the tuning, the subsequent function code for P04

*

appears on the keypad.

Figure 4.1-4

The speed controller is initially set to a low value to avoid hunting. However, hunting may occur during

tuning due to dependency on the machinery. In this case, a tuning error (

er7

) or speed mismatch erro

Loading...

Loading...