12.4 Common Specifications

12-16

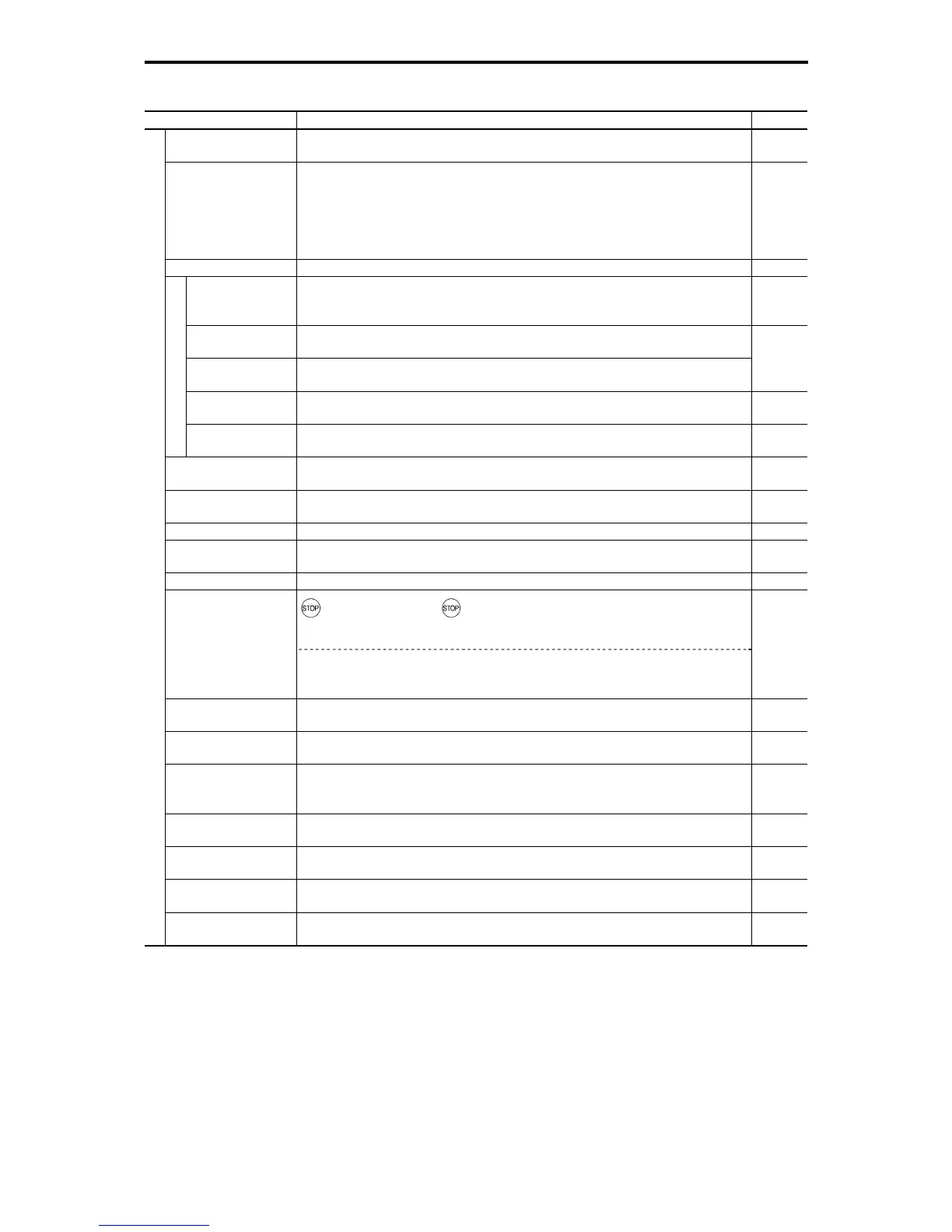

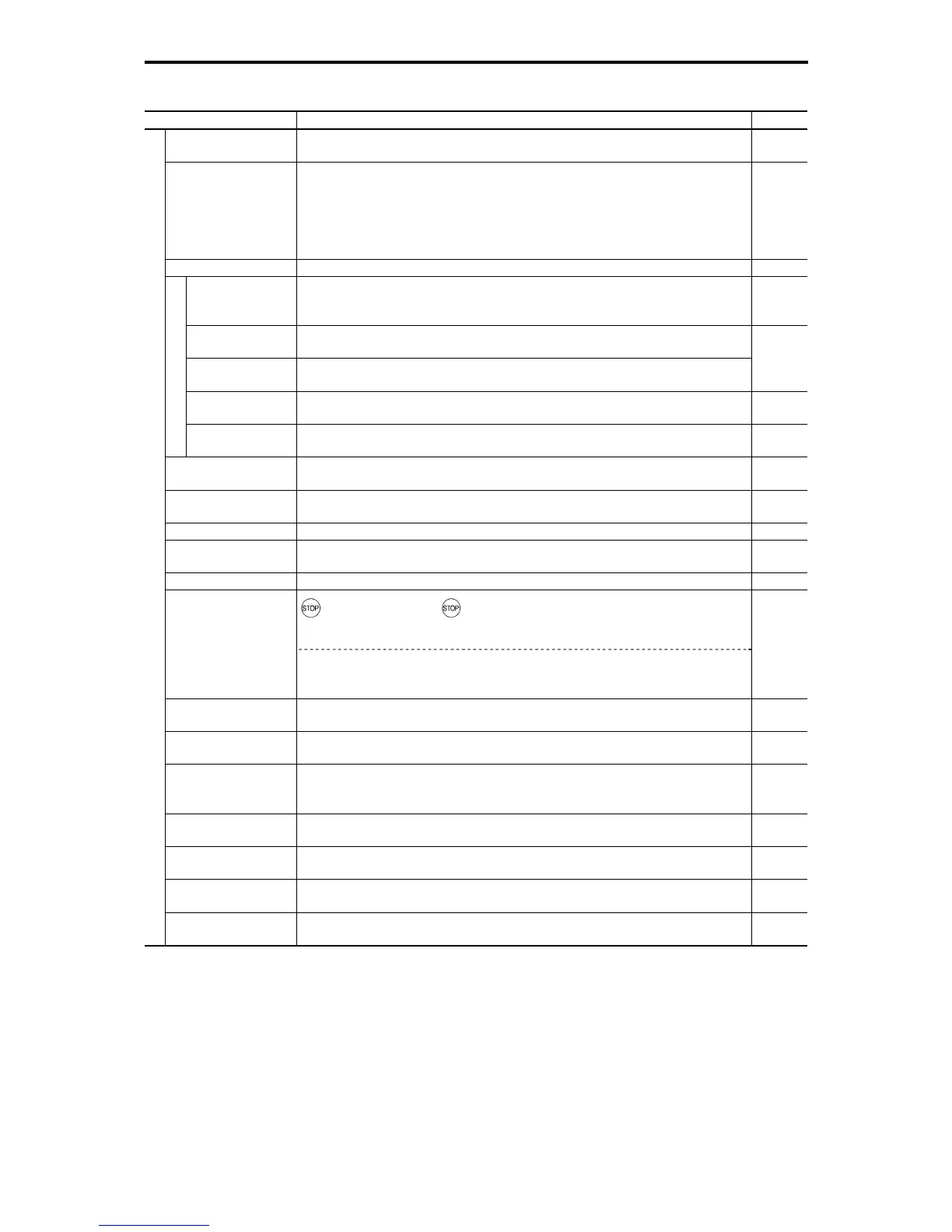

Table 12.4-6

Item Explanation Remarks

Braking transistor broken

Stop the inverter detecting the brake transistor abnormality.

(DB transistor built-in type only)

dba

Overspeed protection

• When d35 = 999, stops the inverter if the detected speed is 120% or over of the maximum output

frequency ¯ (d32 or d33). *4 to *7

• When d35 ≠ 999, stops the inverter if the detected speed is greater than or equal to the

maximum output frequency ¯ (d35). *6

• Stops the inverter if the detected speed is 120% or over of 120 Hz. *6

• Stops the inverter if the detected speed is 120% or over of 200 Hz. *7

0s

*11

PG wire break *4, *5, *7 Stop the inverter output if a PG wire break is detected.

pg

Electronic thermal

The inverter is stopped with the electronic thermal function set to protect the motor.

Protects the general-purpose motor inverter over all frequency range.

(The running level and thermal time constant (0.5 to 75.0 min) can be set.)

0l1

to

0l4

PTC thermistor

The PTC thermistor input stops the inverter to protect the motor. Connect the PTC thermistor

between terminals [V2

] and [

11] and set the switch on control print board and the function code.

NTC thermistor

The NTC thermistor detects a motor temperature. Connect the NTC thermistor between terminals

[V2

] and [

11] and set the switch on control print board and the function code.

0h4

NTC thermistor

breaking

Stop the inverter output detecting the built-in motor NTC breaking.

nrb

Motor protection

Overload early

warning

Warning signal (0L) is output at the predetermined level before stopping the inverter with

electronic thermal function. This function exclusively applies to the 1st motor.

Memory error detection

Data is checked upon power-on and data writing to detect any fault in the memory and to stop the

inverter if any.

er1

Keypad communications

error

When the keypad is used to enter run commands to the inverter, this function stops the inverter

upon detecting a communication fault between the keypad and inverter.

er2

CPU error (detection) Stop the inverter detecting a CPU error or LSI error caused by noise.

er3

Option communications

error (detection)

When each option is used, a fault of communication with the inverter main body is detected to stop

the inverter.

er4

Option error (detection) When each option is used, the option detects a fault to stop the inverter.

er5

key priority: Pressing the

key on the keypad or entering the digital input signal will

forcibly decelerate and stop the motor even if the operation command through signal input or

communication is selected.

er6

will be displayed after the stop.

Operation protection

Start check: If the running command is being ordered when switching the running command

method from power-on, alarm reset, or the linked operation, the operation starts suddenly. This

function bans running and displays

er6

.

er6

Tuning error detection

Stop the inverter output when tuning failure, interruption, or any fault as a result of tuning is

detected during tuning for motor constant.

er7

RS-485 communications

error (port 1)

When the inverter is connected to a communications network via the RS-485 port designed for the

keypad, detecting a communications error stops the inverter output.

er8

Speed mismatch or

excessive speed deviation

*4 to *7

Stop the inverter output if the speed deviation (difference between the speed command value and

the feedback value) exceeds the preset value.

ere

Data save error upon

undervoltage

If the data could not be properly saved during activation of the undervoltage protection function,

the inverter displays the alarm code.

erf

Excessive position

deviation *4,*5,*7

Stop the inverter output if the position deviation (difference between the target position and the

current position) exceeds the preset value.

ero

*10

RS-485 communications

error (port 2)

When the inverter is connected to a communications network via the RS-485 port on the control

terminals DX+ and DX-, detecting a communications error stops the inverter output.

erp

Protection

Hardware error

Stop the inverter output upon detecting a malfunction of LSI on the power printed circuit board,

which is mainly caused by noise.

erh

*4 Available under V/f control with speed sensor. (PG option required)

*5 Available under dynamic torque vector control with speed sensor. (PG option required)

*6 Available under vector control without speed sensor.

*7 Available under vector control with speed sensor. (PG option required)

*10 Available in inverters having a ROM version 3000 or later.

*11 Available in inverters having a ROM version 3600 or later.

Loading...

Loading...