Use e Maintenance ENGLISH

4.7.11 Parking the machine

The machine must be cleaned of any fertiliser residues

before parking.

Fertilisers mixed with the humidity in the air are

extremely corrosive. Keeping the machine clean

means prolonging its duration over time.

Do not park the fertiliser spreader in direct contact with

the ground. If possible, park the machine on a wooden

pallet.

Always park the machine on even, compact ground.

Only park the machine if the hopper is empty.

Using the storage wheels (optional)

The storage wheels allow you to easily move the machine

once unhooked from the tractor.

To assemble the storage wheels, proceed as follows.

DANGER!

All operations must be done exclusively with the

tractor off, P.T.O. disengaged, parked with

parking brake and with the key removed.

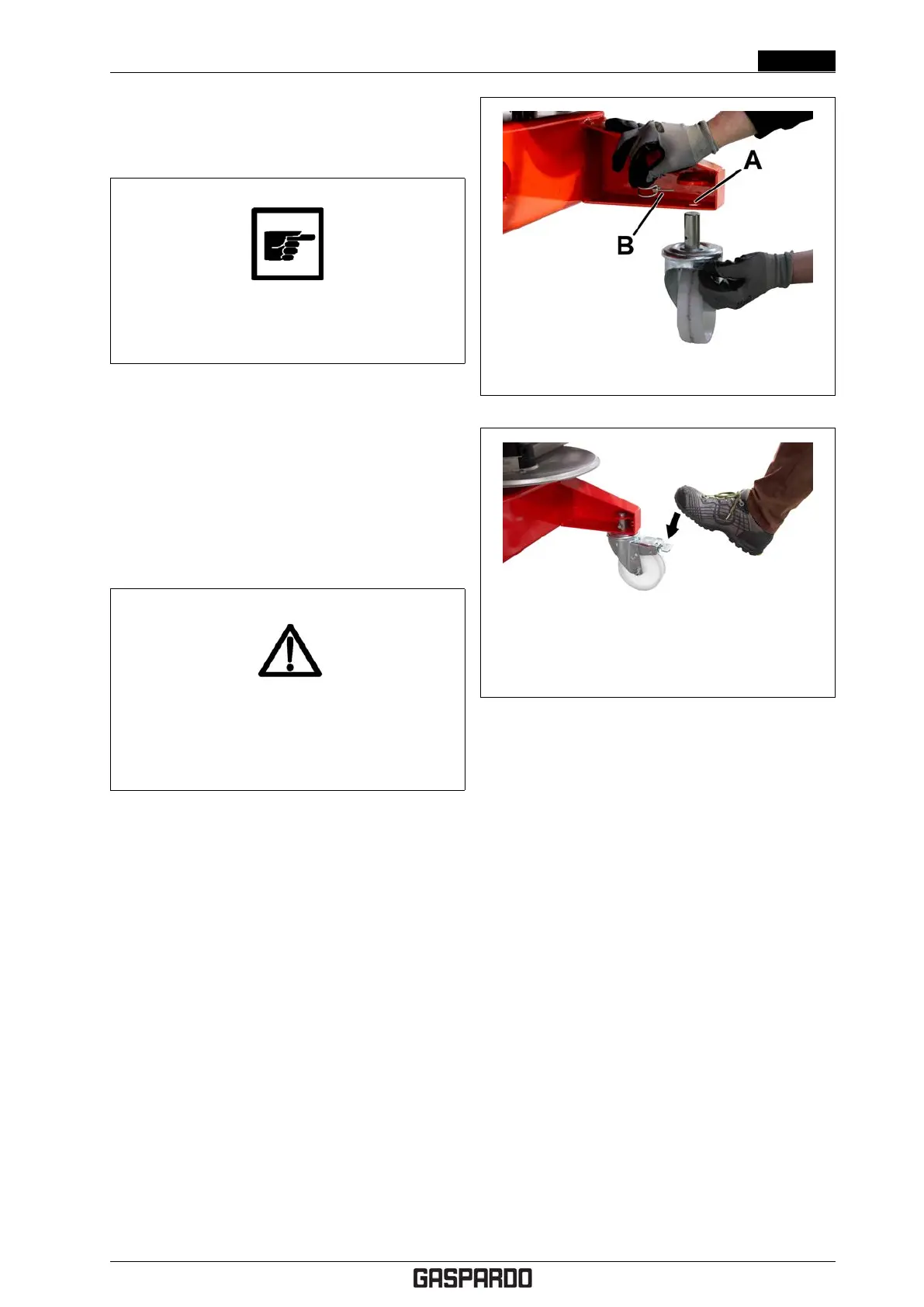

1. With the machine lifted, insert the 4 wheels in their

housing (A) see fig. 4.29 and lock the wheels with

the specific elastic pin (B).

2. Lower the machine to the ground and unhook it from

the tractor (see § 4.1.2 on page 21).

3. Push the machine to the storage area. Make sure the

ground is even and compact.

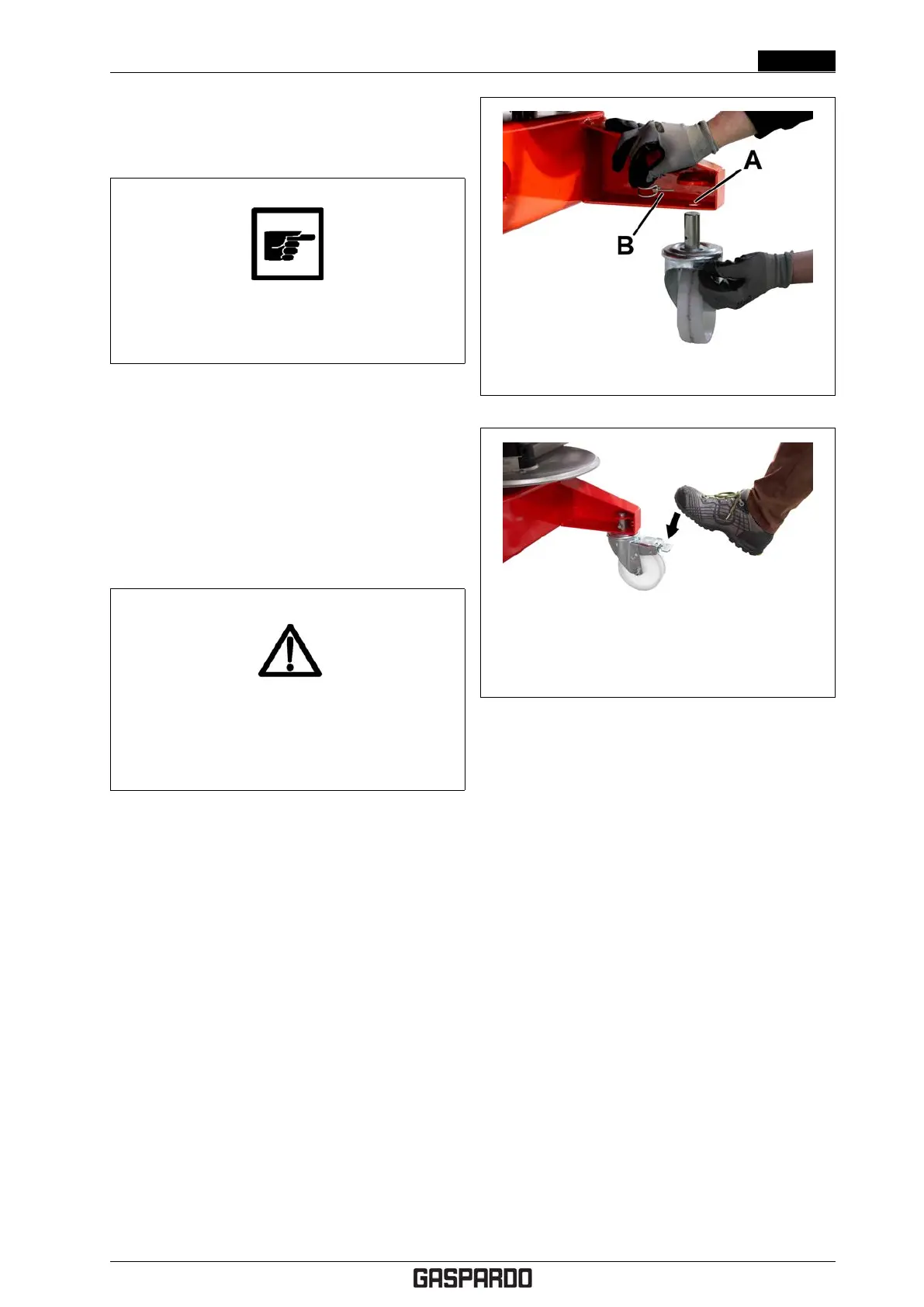

4. Frenare le ruote di rimessaggio premendo

sull’apposito pedale di frenatura (vedi fig. 4.30).

4.8 HOW TO WORK

The PRIMO centrifugal fertiliser spreader was designed

exclusively for normal use in agricultural work and is suit-

able to spread dry, granulated, pellet and crystal fertilisers,

seeds and snail and slug bait.

All the adjustments for proper fertiliser spreading are

made according to spreading tables created based on

tests done at specialised laboratories. Despite everything,

even following the instructions to adjust the machine ex-

actly, we cannot exclude variations in spreading compared

Figure 4.29: Storage wheels

Figure 4.30: Storage wheels - wheel brake

to the expected results. Before starting to spread a new

fertiliser, it is essential to proceed with the machine cali-

bration operations as shown in § 4.7.8, 4.7.9 and 4.7.10.

Below is a list of the main causes that lead to variations

in spreading quality.

• Variations in the physical features of the fertilisers or

seeds. In particular, fertilisers have physical features

(granule size and shape, specific weight, degree of

humidity, etc.) that can vary for the same fertiliser

even based on the production batch (same type and

brand).

• Weather variations that change how well the fertiliser

slides.

• Storage conditions that may make it easier for lumps

to form in the product to be spread.

• Uneven or not flattened soil.

• Excessive wear in the spreading parts (vanes, discs,

agitator).

• Excessive wind.

• Incorrect rpm and drive speed.

• Machine not adjusted properly.

• Adjustment tests not run.

• Poor machine cleanliness.

Cod. F07011577 EN - 37

Loading...

Loading...