ENGLISH Use e Maintenance

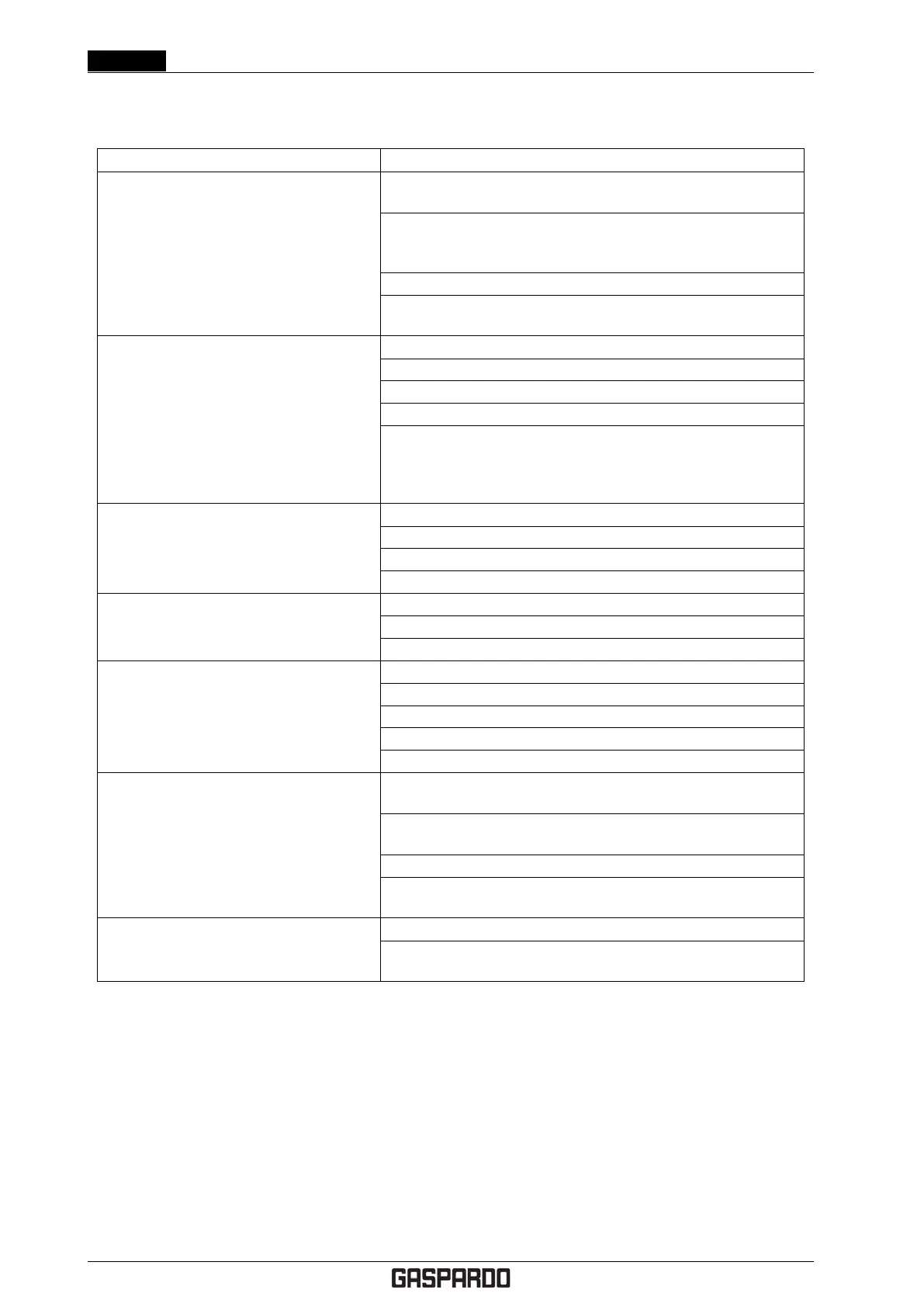

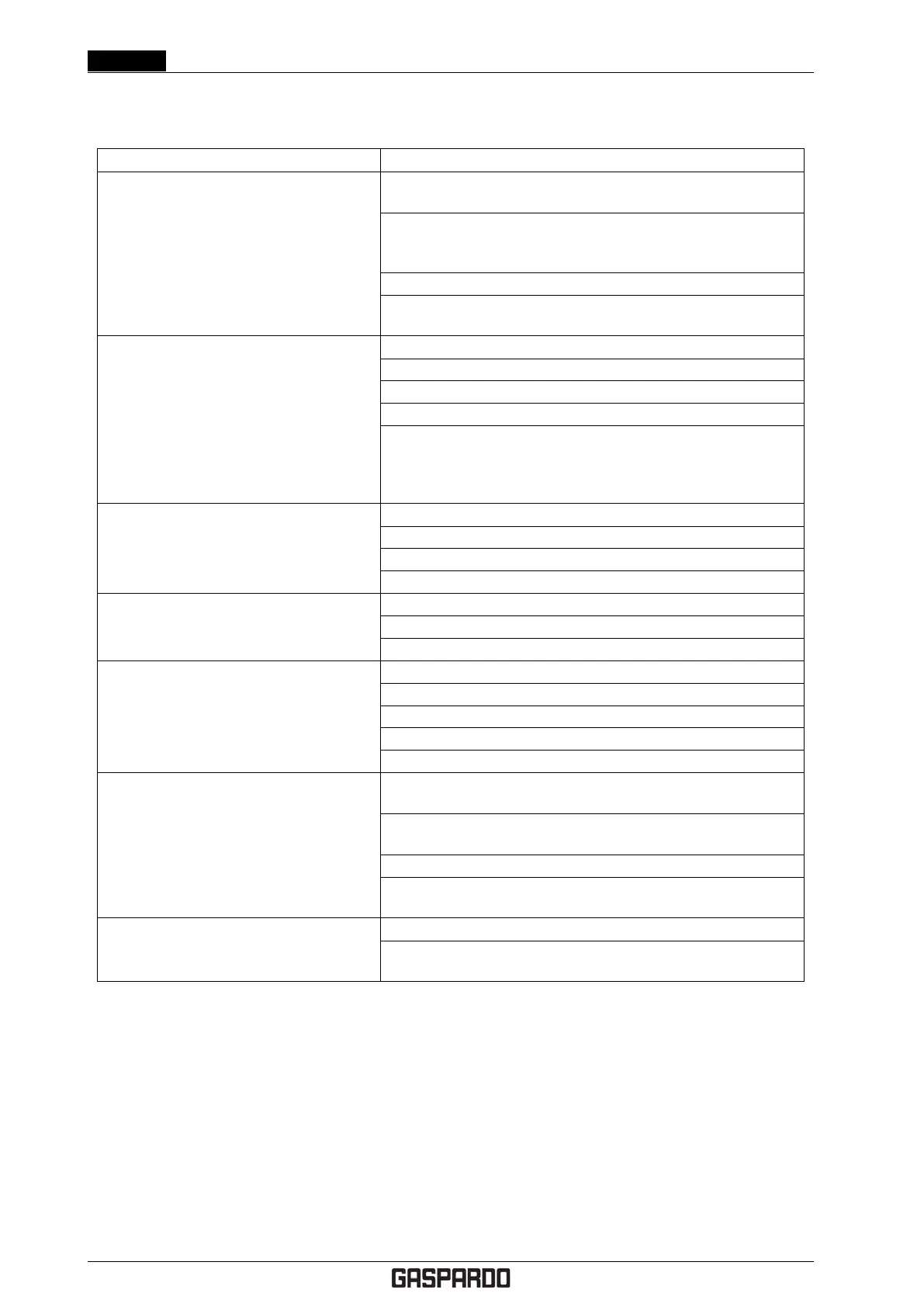

5.11 MAINTENANCE PLAN

TIME OPERATION

FIRST 8 HOURS OF WORK

After the first 8 hours the machine is made to work, thor-

oughly check the general state of the machine itself

In particular, after having checked the wear on the spread-

ing vanes, further tighten the screws that secure the vanes

to the disc.

Make sure the spreading disc locking handwheels are tight.

Make sure the screws and bolts on the whole machine are

tight.

EVERY 8 HOURS OF WORK

Grease the Cardan shaft crosses.

Make sure the spreading vane fastening bolts are tight.

Make sure the spreading disc locking handwheels are tight.

Make sure the electrical/electronic system cables are intact.

Check the state of wear and the integrity of the tractor con-

necting elements and of the structural elements. The ma-

chine cannot be used if anomalies are noted. Contact your

dealer immediately.

EVERY 50 HOURS OF WORK

Grease the Cardan shaft crosses.

Greasing

Make sure the screws on the drive parts are tight.

Check the wear on the spreading parts (see § 5.1)

DAILY

Check the wear on the spreading vanes.

Make sure the spreading disc locking handwheels are tight.

Clean the machine at the end of every day

AS NEEDED

Replace the spreading vanes.

Calibrate the dosing shutters (see § 5.5).

Calibrate the drop point (see § 5.6).

Check the load cell (see § 5.4).

Check the agitator shaft drive hub (see § 5.8).

PUTTING IN STORAGE

Wash the machine, dry it and coat it with a protective layer

of environmentally friendly anticorrosive.

Thoroughly check for and, in the event, replace damaged or

worn parts.

Tighten all the screws and bolts completely.

Thoroughly grease the machine and finally, cover all the

equipment with a tarp and store it in a dry place.

PUTTING IN USE

Check all the greasing points; if necessary, add grease.

Make sure all the screws are tight and, if necessary, tighten

them.

44- EN Cod. F07011577

Loading...

Loading...