Use e Maintenance ENGLISH

DANGER!

In order to completely empty the hopper, it may

be necessary to turn on the tractor and bring the

P.T.O. to 540 rpm.

Before activating the P.T.O., make sure that no

one is near the tractor.

DANGER OF DRAGGING BY ROTATING PARTS.

NEVER get out of the cab until the hopper is

completely empty.

Once the hopper is empty, disconnect the P.T.O.

and turn off the tractor before getting off.

In case of danger, stop the P.T.O. immediately

and turn off the tractor.

Once the hopper is empty, reassemble the spreading

discs and wash the machine (see § 5.2).

5.4 LOAD CELL CHECK

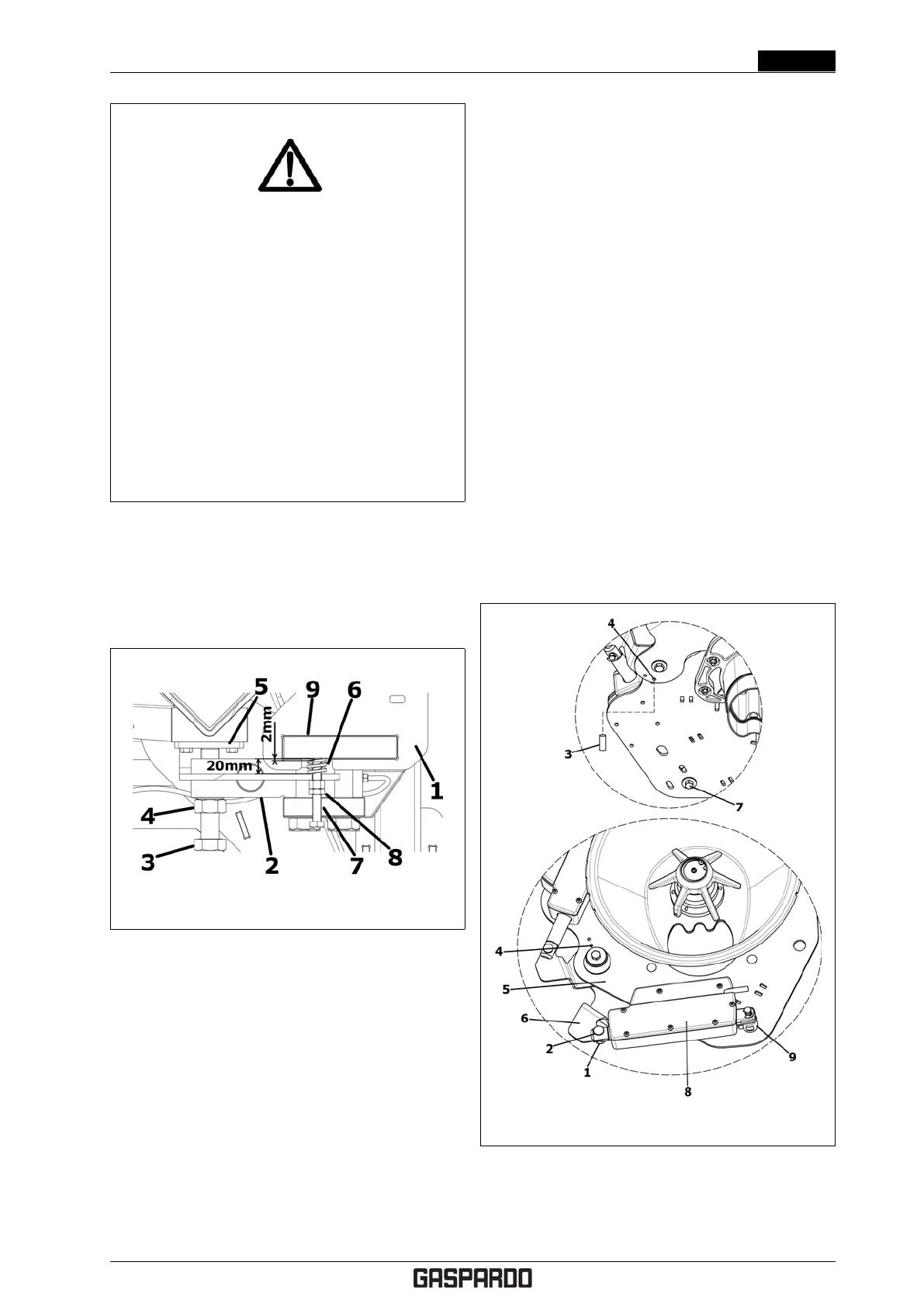

Figure 5.1: Load cell check

With reference to fig. 5.1 you have:

1. Weighing frame.

2. Load cell.

3. Adjustment screw.

4. Locking counternut.

5. Cell support.

6. Limit spring.

7. Limit screws.

8. Locking counternut.

9. Frame support.

Should the weighing system become inaccurate and dif-

ficult to calibrate (to calibrate the weighing system, refer

to the control system instructions manual), the adjustment

screw (3) ) may be loose or may have gone into the sup-

port (5).

In this case, you must check proper positioning of the

load cell.

1. Loosen the counternut (4).

2. Adjust the screw (3) until the springs (6) reach a

length of 20 mm.

3. Tighten the locking counternut (4).

4. Loosen the counternuts (8) and adjust the limit

screws (7) until they are 2 mm from the support (9)

.

5. Tighten the locking counternuts (8).

Once the load cell positioning adjustment is complete,

you must re-calibrate the weighing system (see the control

system instructions manual).

5.5 CALIBRATING THE DOSING

SHUTTER

Check dosing shutter adjustment at the beginning of every

season and every time you notice a difference in wear on

the two sides of the machine.

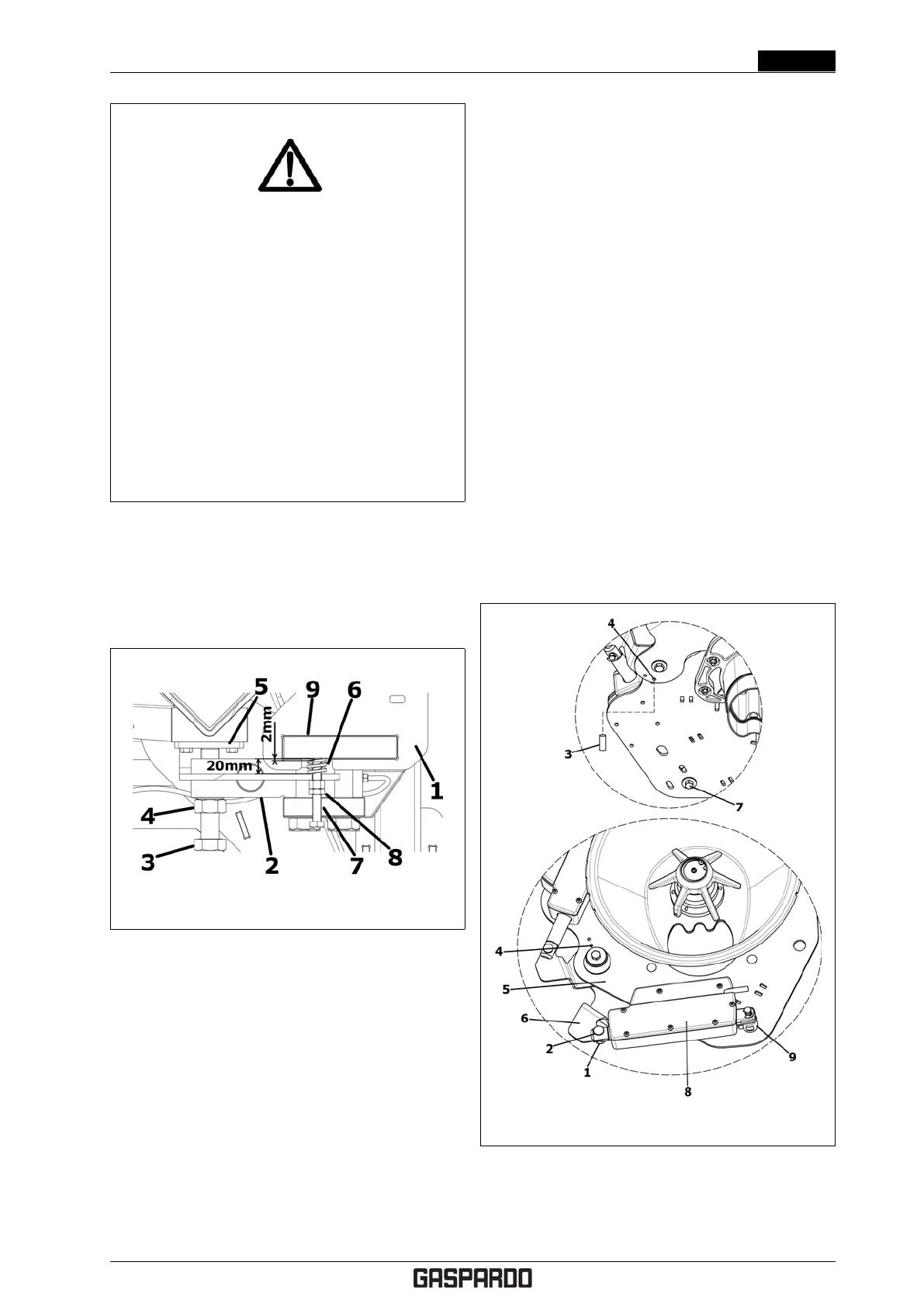

Figure 5.2: Calibrating the dosing shutter

With reference to fig 5.2 to calibrate the dosing shutter,

proceed as follows.

Cod. F07011577 EN - 41

Loading...

Loading...