Niro Soavi S.p.A

PRESSURE CHECK

The pressure gauge located on the front panel is used to measure the pressure

in the lubricating circuit.

During the final machine test optimal lubrication pressure is calibrated under

steady operating conditions; this value is largely affected by oil viscosity and

temperature so when the machine is started pressure is usually high and then

tends to decrease and become stable as the machine warms up with operation.

If pressure drops too low at high temperatures this may be due to problems with

the cooling system of the water/oil exchanger (where used) connected with

scaling or very high water temperature.

The water temperature must conform with the values given in Section 1 –

TECHNICAL SPECIFICATIONS.

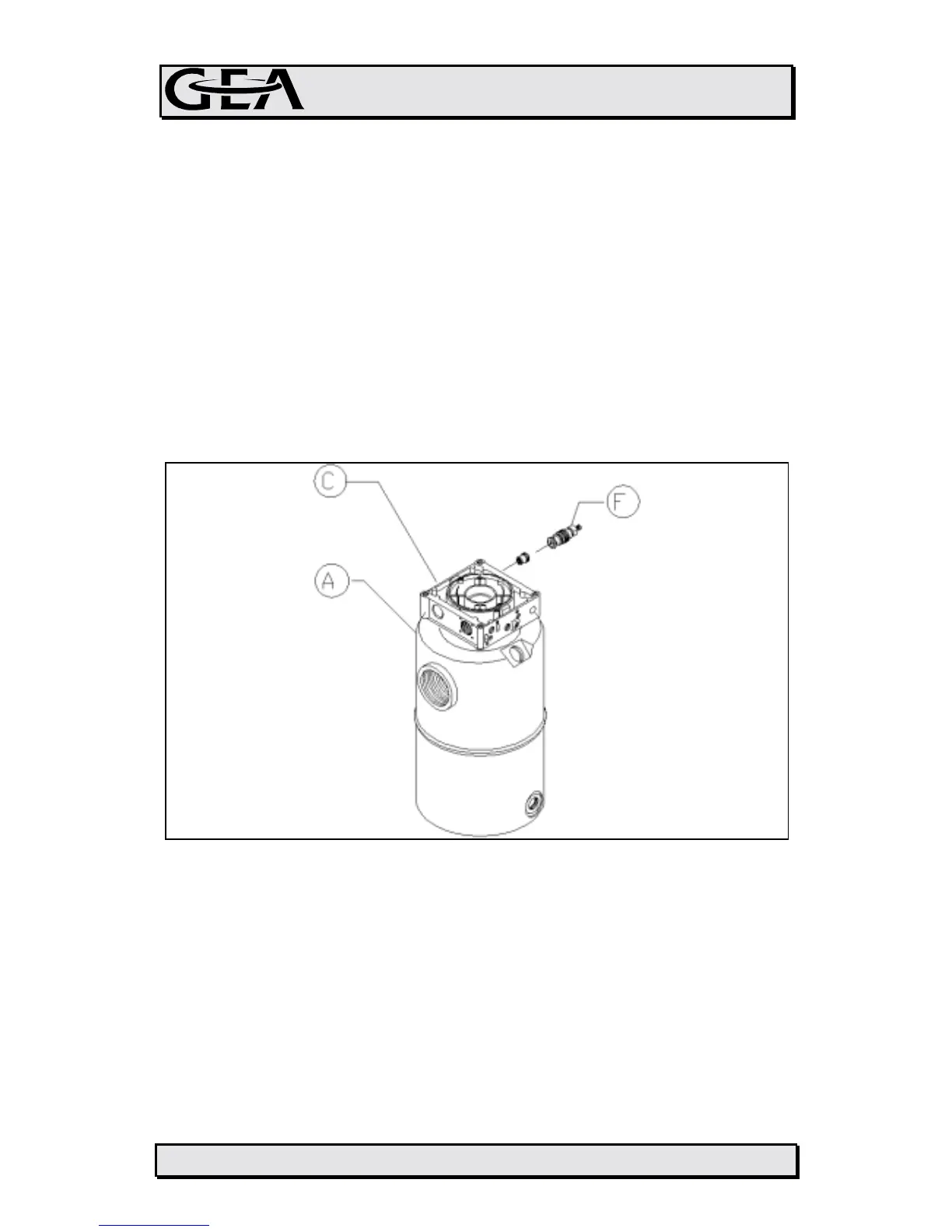

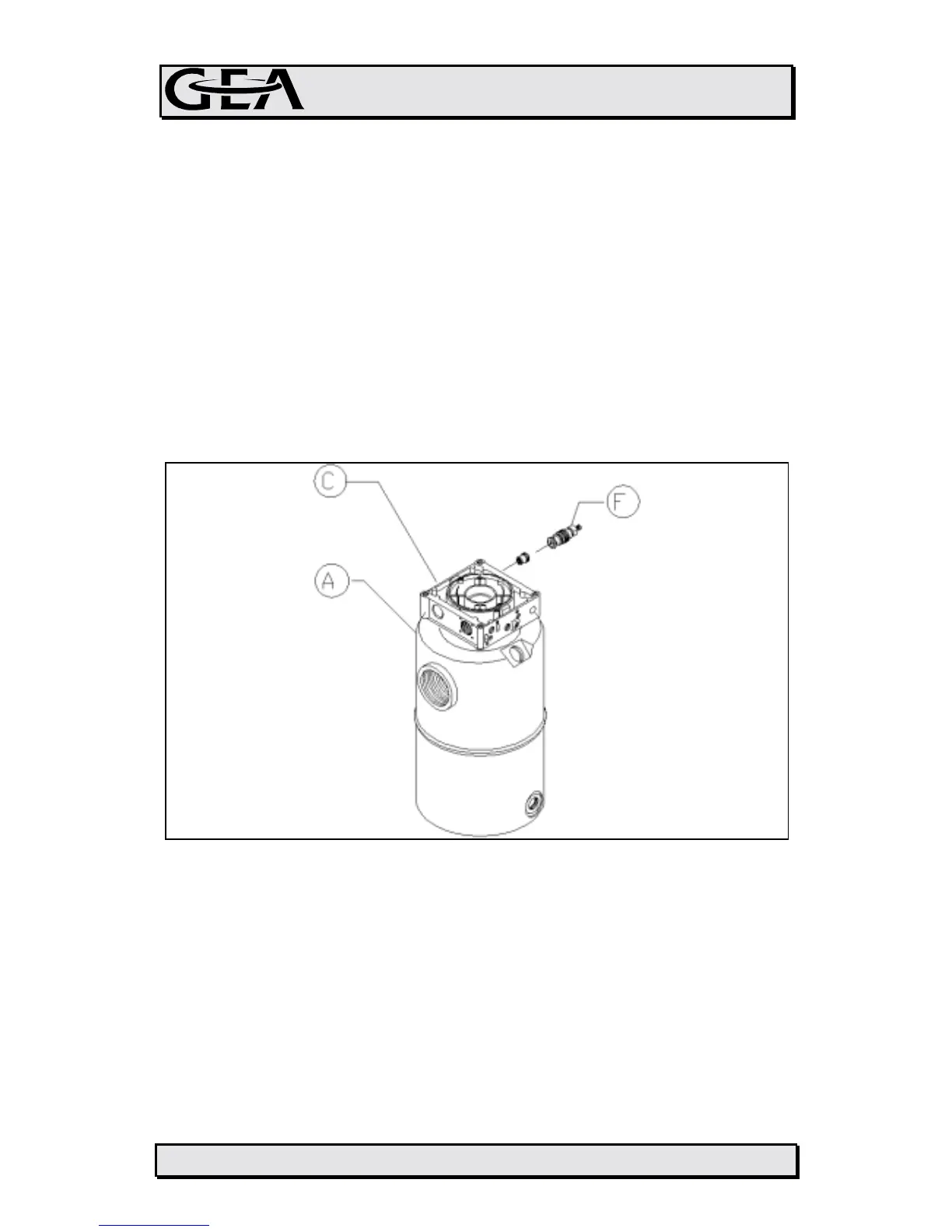

The pressure in the lubrication circuit can be adjusted via the by-pass valve (F)

in the lubrication unit body (C) (figure 4.9.2):

FIGURE 4.9.2

− DO NOT REMOVE THE VALVE FROM THE BODY

− Loosen the lock nut and turn the Allen screw (Allen spanner) to reach the

correct pressure value

− Turn the screw CLOCKWISE to increase pressure and

COUNTERCLOCKWISE to reduce it

− Tighten the lock nut.

Adjustments must be made at high temperatures, with a value of approximately

5÷6 bar.

4c091e0c.doc 4.9.6

Loading...

Loading...