39

!

"

#

$

%

&

!

"

#

$

%

&

!

"

#

Saw-Spindle Moulder

B3 / B3 e-classic

Making adjustments and preparations

8.3 Crosscut fence on the sliding table

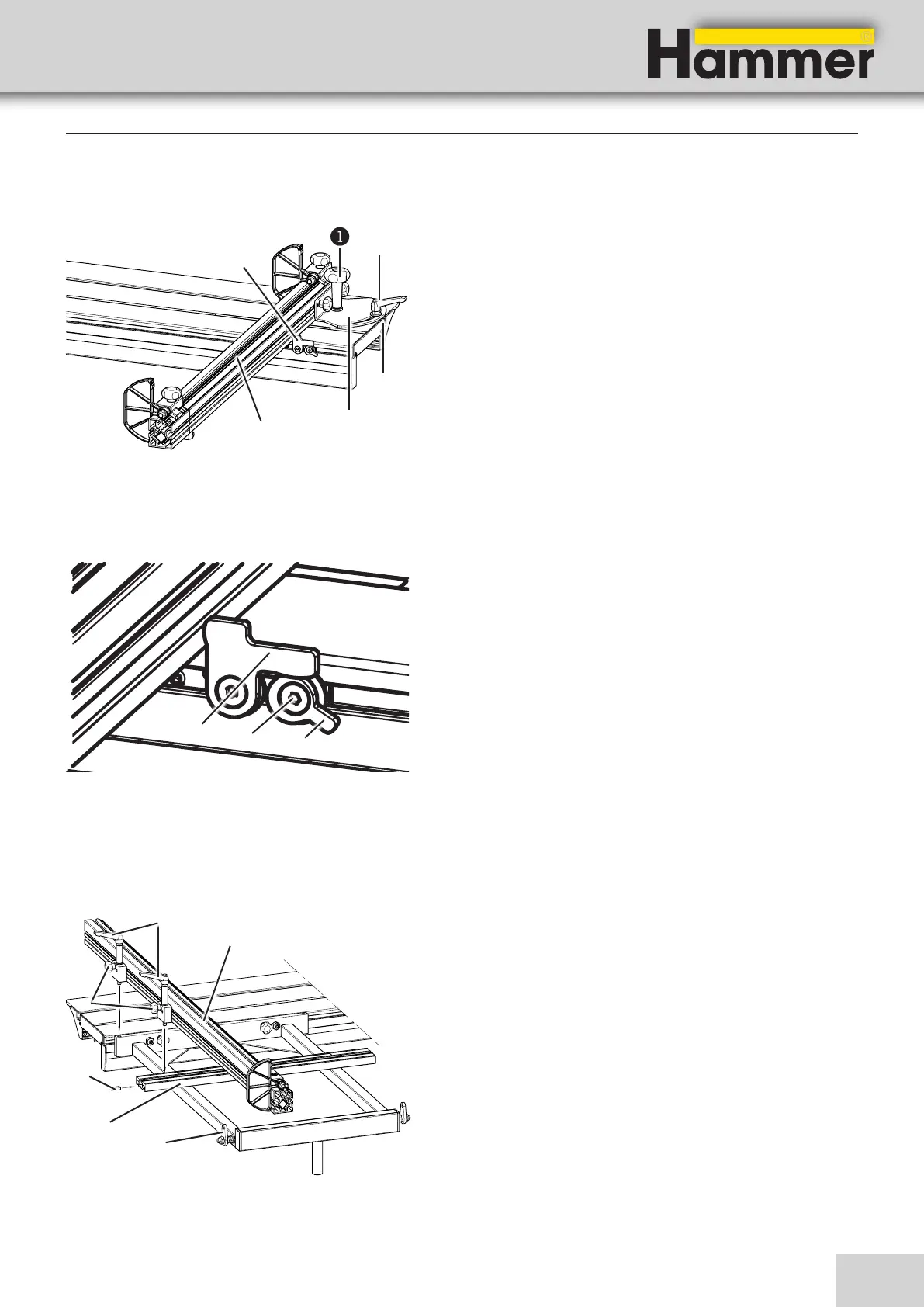

Fig. 8-2: Assembling the crosscut fence

1. Thread the clamping device of the crosscut fence into

the groove of the sliding table and move it right up to

the stop screw (in the groove).

2. Loosely affix the compressor rod shaft.

3. Adjust the desired cutting angle (-45° to +45°).

With 90° cuts:

• Flip open the end stop on the sliding table.

• Place the fence against the end stop.

4. Clamp the stop with the clamping lever.

! Compressor rod shaft $Clamping device

" Single-hand clamp lever %End stop

# Groove &Stop

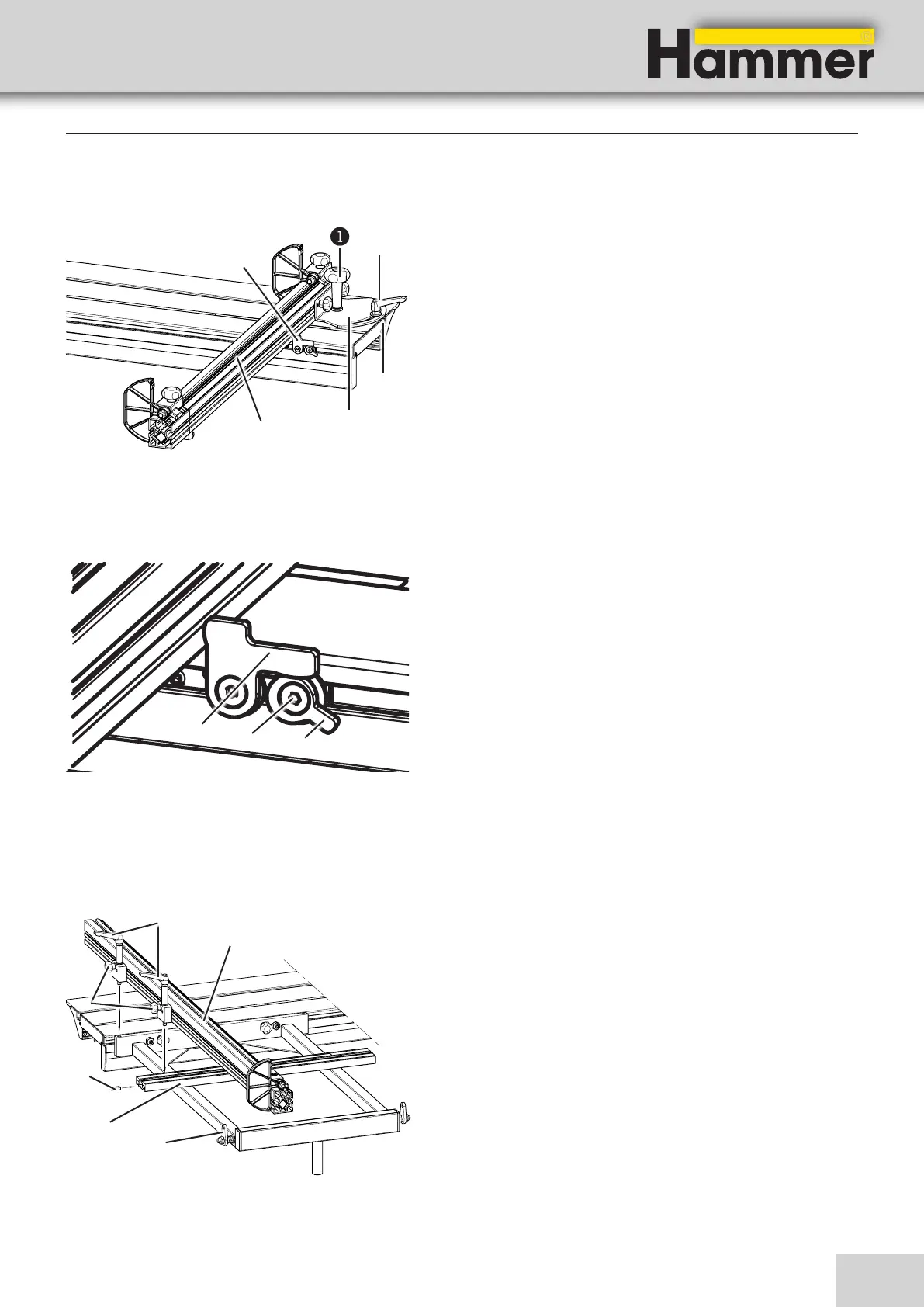

Fig. 8-3: Adjusting the end stop

Adjusting:

1. Fold the end stop back.

2. Loosen the setscrew.

3. Turn the cam lever until a 90° angle is attained (the

fence reaches the end stop).

4. Check with a sample cut.

5. Tighten the setscrew.

! End stop

" Setscrew

# Cam lever

8.4 Crosscut fence on the outrigger

Fig. 8-4: Assembling the crosscut fence

The crosscut fence can be mounted onto the outrigger on

the push side.

1. Thread the locking plate into the outrigger rail.

2. Loosen the thumb screws and position the crosscut

fence at the outrigger.

3. Clamp the crosscut fence at the outrigger with the

clamping lever.

4. Tighten the thumb screws.

! Clamping lever $Outrigger

" Crosscut fence %Locking plate

# End stop &Thumb screws

Loading...

Loading...