57

#

!

"

!

"

#

$

Saw-Spindle Moulder

B3 / B3 e-classic

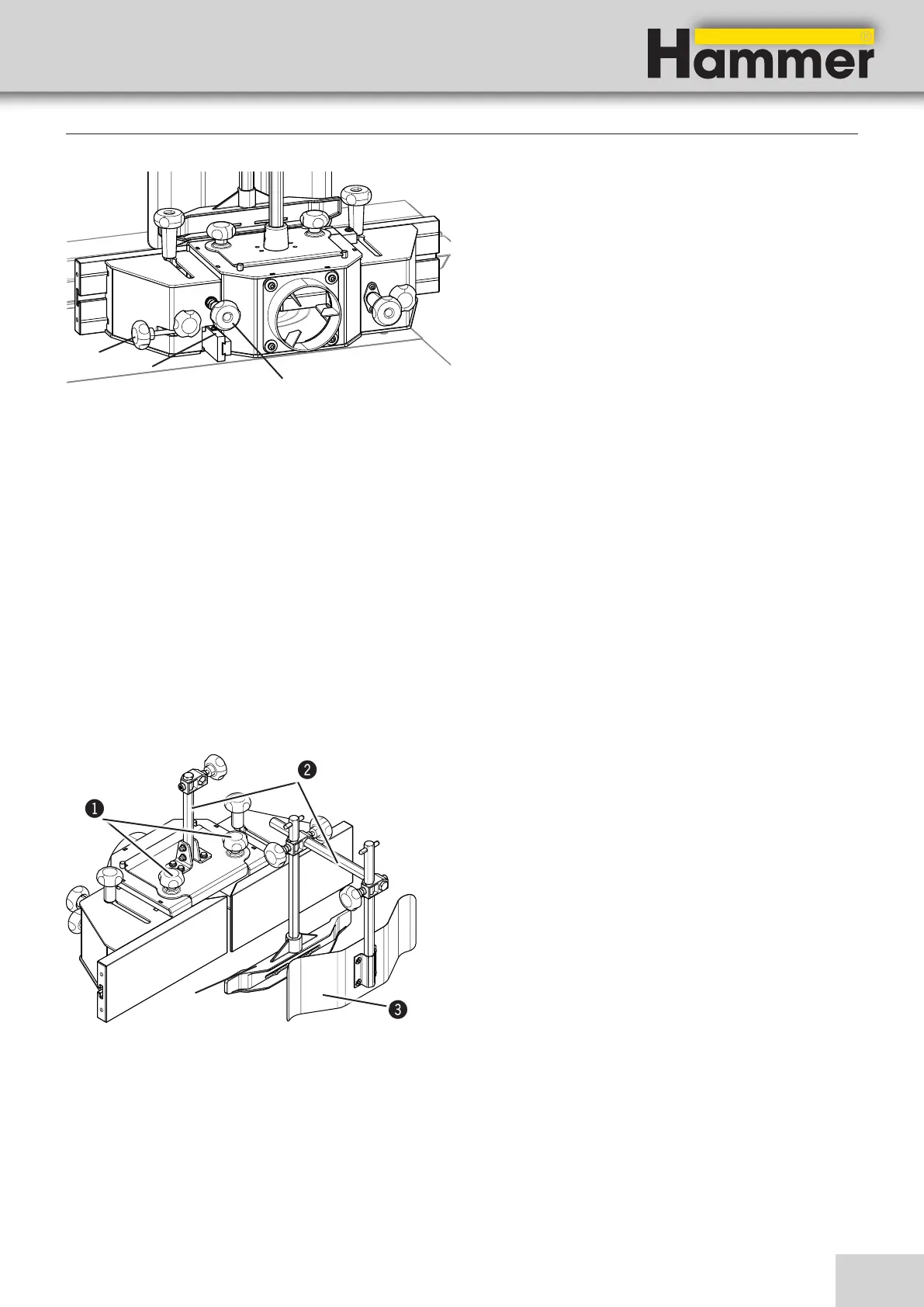

The spindle moulder guard unit is mounted on the moul-

ding fence. It consists of an adjustable linkage, the pres-

sure shoe and the pressure spring.

1. After releasing the thumb screws, the individual com-

ponents can be adjusted vertically and horizontally.

2. The vertical pressure shoe and the horizontal pressu-

re spring are adjusted in such a way so as to lightly

bias (pressure) the workpiece against the table and

respectively against the fence boards.

3. To change tools, open the thumb screws and open

the moulding fence cover with the installed spindle

moulder guard toward the back.

!Thumb screw $Pressure shoe

"Rod #Pressure spring

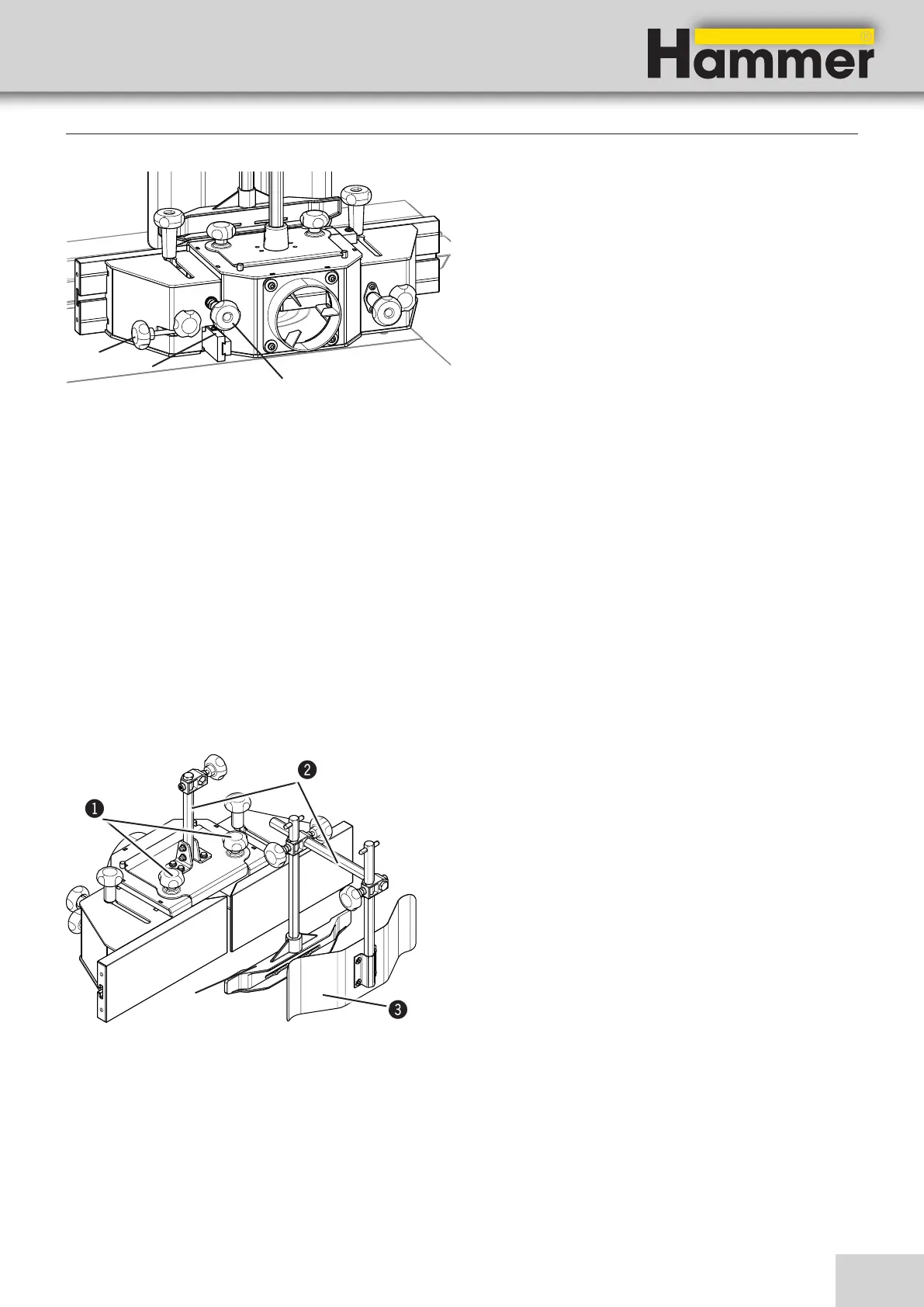

Fig. 9-5: Fine adjustment for outer tool diameter

2. After opening the outer tool diameter clamping

screw, adjust the shaper fence roughly in relation to

the outer tool diameter.

3. Tighten the outer tool diameter clamping screw.

4. Now you can fine adjust the entire shaper fence to

the outer tool diameter via the handwheel.

5. On scale, you can directly read the outer tool diame-

ter to which the rigid straightedge is set.

To ensure that the settings remain unchanged after re-

moving and remounting the shaper fence, you have to

compensate for play in the fitting bolt by always app-

lying light pressure backwards on the depthadjustable

straightedge when setting. After adjusting, tighten the

shaper fence to the machine table via the clamping bolts.

!Circle of cut clamp screw

"Scale

#Handwheel

9.4.3 Spindle moulder guard attachment

Fig. 9-6: Spindle moulder guard

Making adjustments and preparations

Loading...

Loading...