74

X

Gefaket!!

15 mm in Richtung dimetrie 1 verschoben

Schiebetisch, Grundbahn, Handrad Logo

"

!

#

Saw-Spindle Moulder

B3 / B3 e-classic

10.5.9 Groove cuts

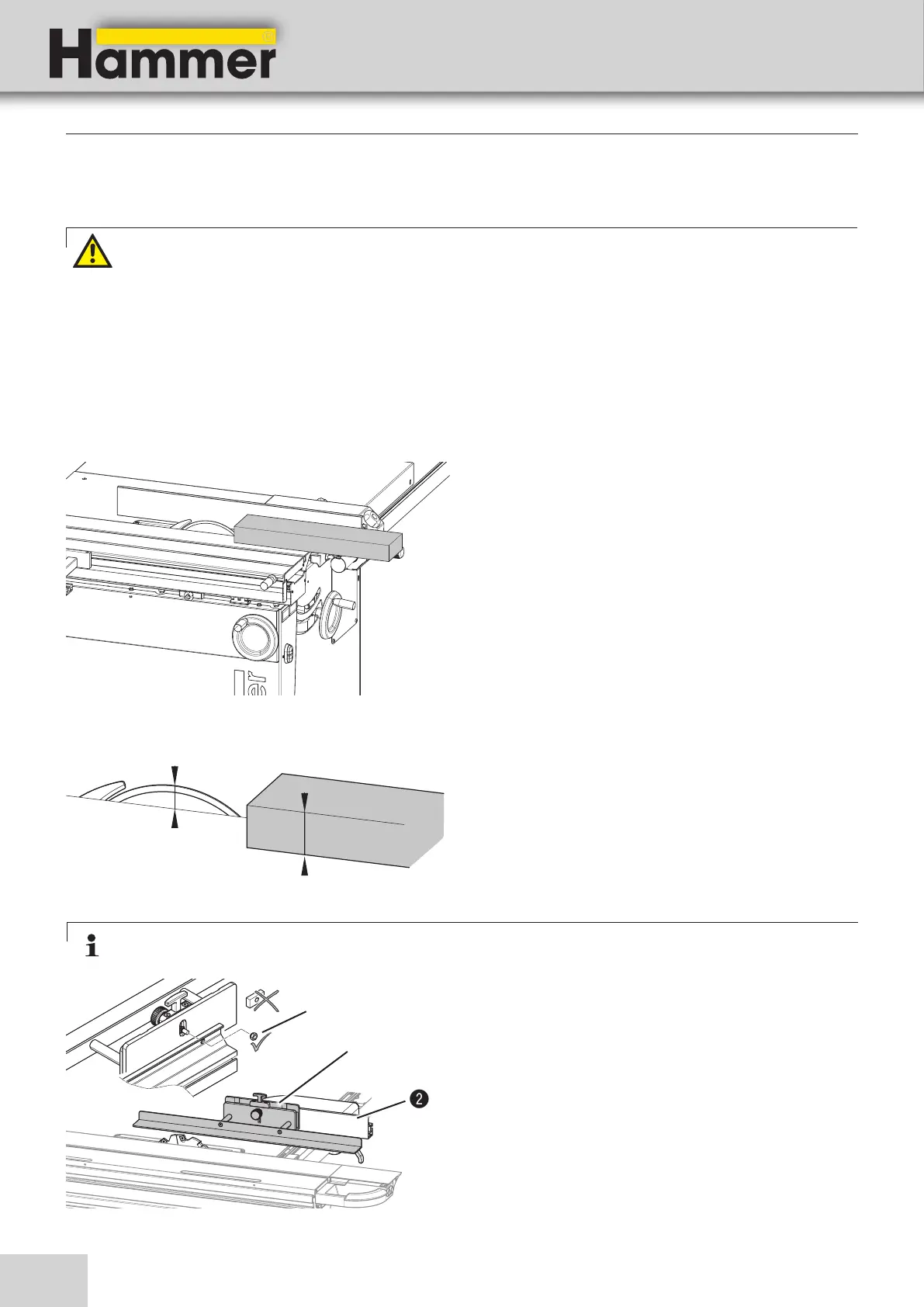

Fig. 10-12: Groove cuts

Fig. 10-13: Groove cuts

1. Take note of general procedures for authorised work-

ing techniques.

2. Set the combination fence to the desired dimensions.

3. Lock the sliding table into a centre position.

4. Set the cutting height to a maximum of half the work-

piece thickness.

5. Select the cut sequence so that the cut batten falls

onto the sliding table side.

Should the cut batten fall to the right side of the circu-

lar saw, a wooden push stick has to be used due to

the high kickback risk!

X Workpiece thickness

X/2 Cutting height

Warning: Risk of injury!

• Groove cuts may only be carried out with an overhead saw guard! Do not, under any circumstances, use

a saw blade guard (guard mounted onto splitter)!

• Do not pull the combination fence‘s guide back!

• Do not remove the splitter!

• If the saw blade is protruding over the top edge of the combination fence‘s guide, there is no guarantee

that the workpiece can be guided safely. A higher auxiliary fence must be used to ensure that the work-

piece is guided safely.

• When working on small workpieces, use a wooden push stick, a push stick or a load feeding accessory.

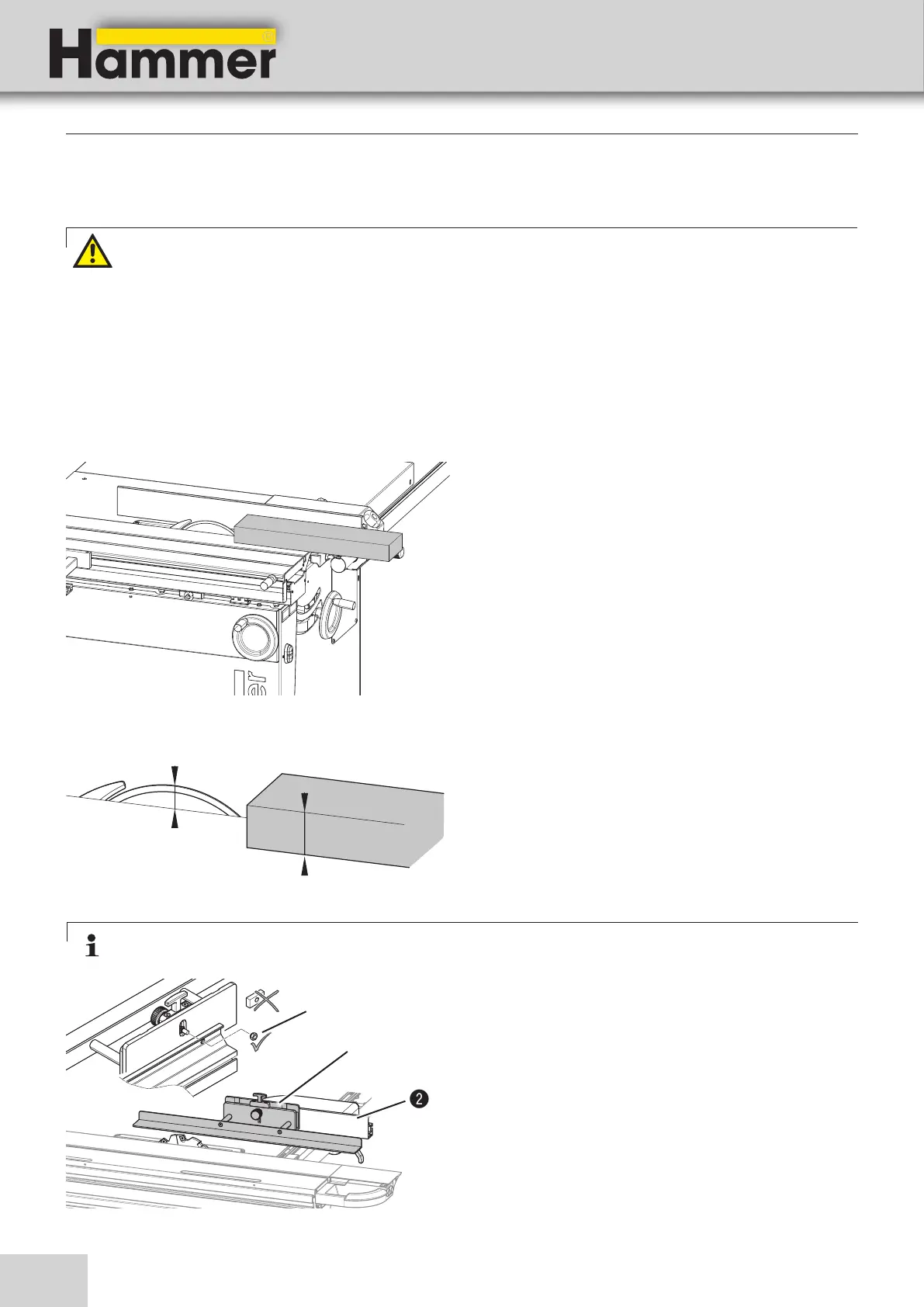

Fasten Sawboy by means of the screw onto the parallel

fence, in the case of a thin-walled fence by means of

said screw and the nut.

Operating and adjusting:

Read individual operation instructions

!Sawboy

"Fence guide

#Special-nut

Fig. 10-14: Auxiliary fence

Note: Tenoning hood and moulding guard „Sawboy“

see: Tools and Accessories catalogue

Operation

Loading...

Loading...