10/6/10 888-2629-200 2-11

WARNING: Disconnect primary power prior to servicing.

Section 2 Installation

Maxiva ULX COFDM Series

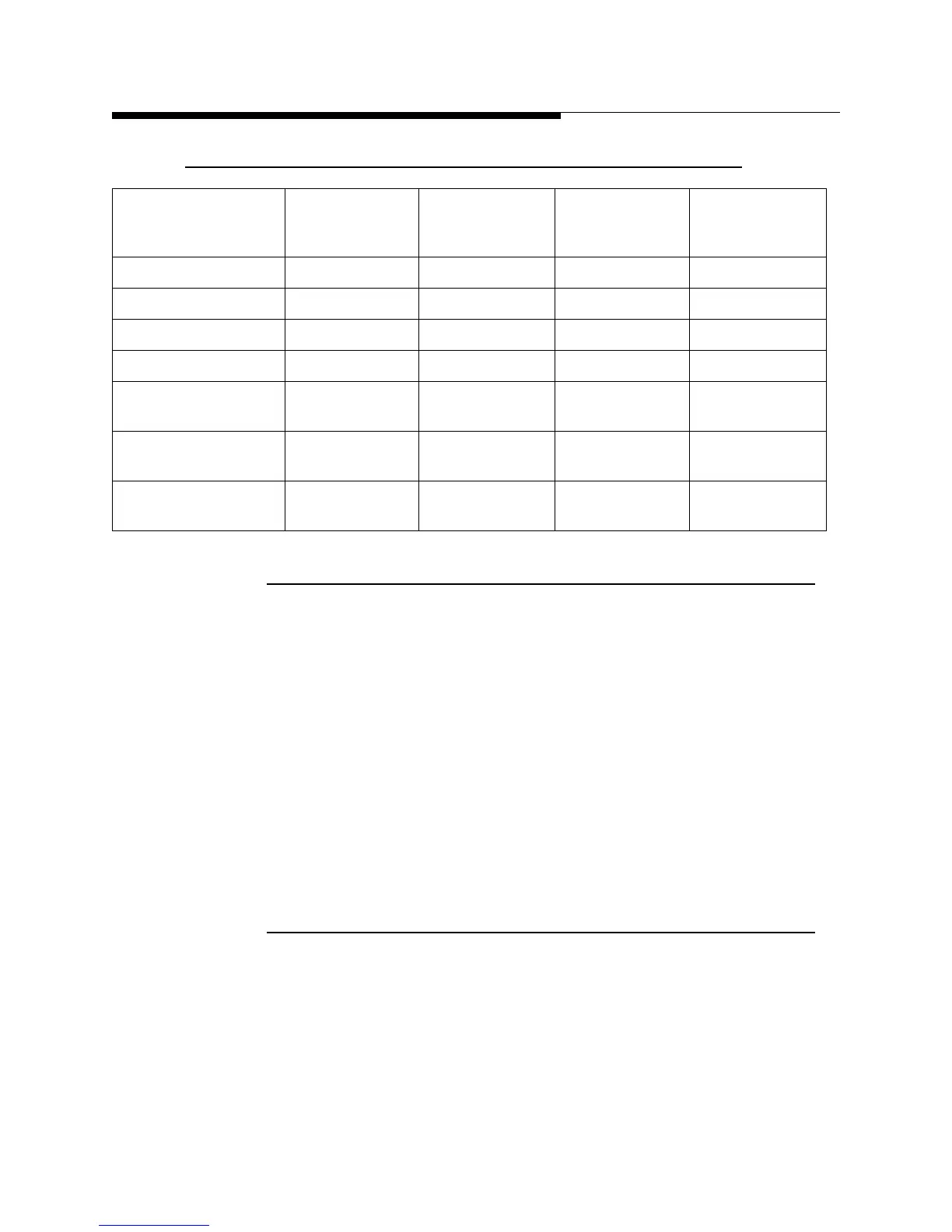

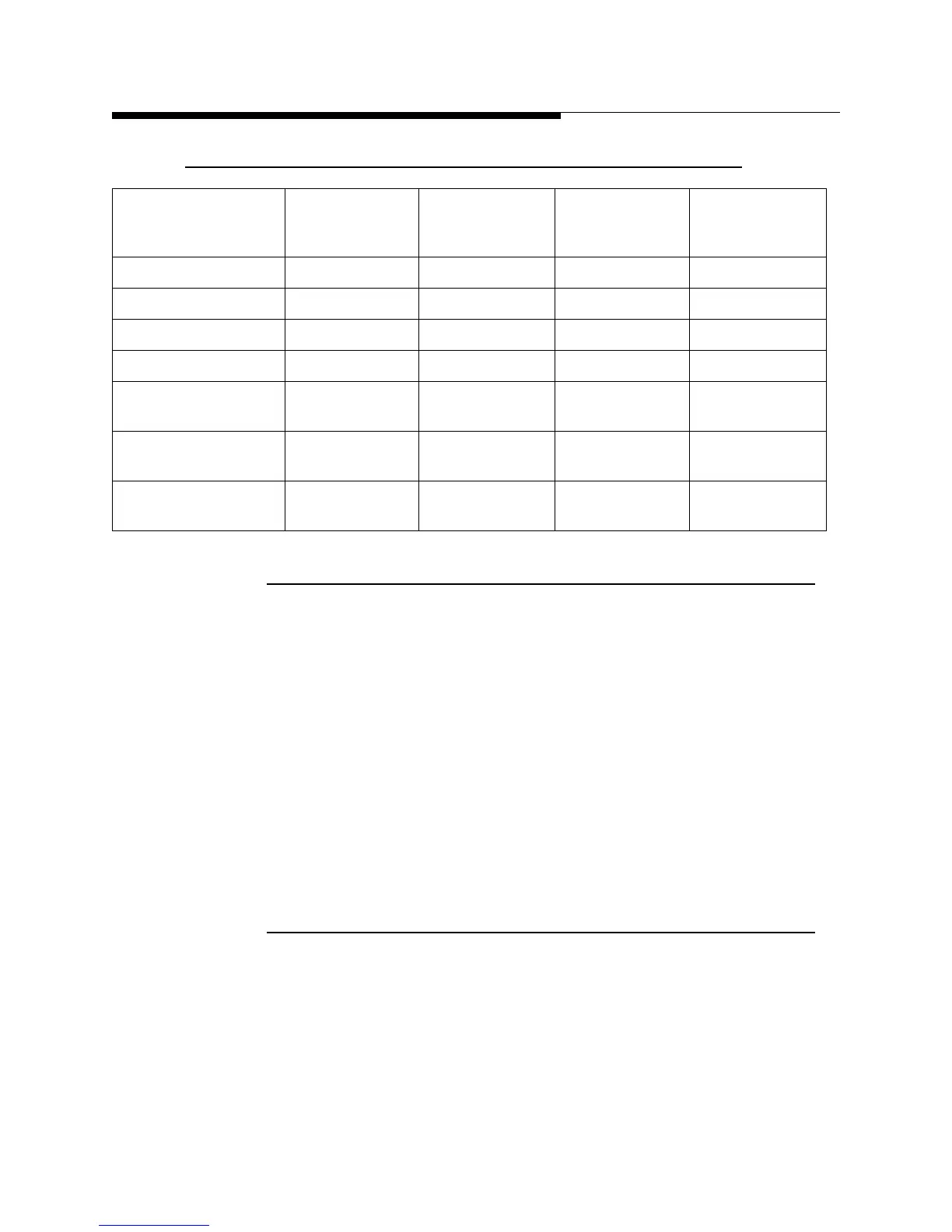

Table 2-5 Line length to Capacity Conversion Factors

2.5.3 Rigging Heat Exchanger & Pump Module

The equipment should be kept on the original pallet until ready for final instalaltion.

When using lifting belts ensure that a spreader bar is used and belts do not compress

sheet metal or plumbing. The exact method of handling and setting the heat exchanger

and pump module depends on the available equipment, the size of the unit, its final

location and other variables. It is the installer’s or mover’s responsibility to determine

the specific method of safely handling each unit. If possible, when the units arrive at the

site and are unloaded from the truck, plan to set and secure the heat exchanger in its

permanent place on its concrete pad or on the roof. The pump module (with control

panel) should immediately be moved to an indoor location. Refer to the section Figure

2.5.5 for heat exchanger & pump placement information. If required, complete any

required assembly of the unit. See paragraph 2.5.5, Placement of Heat Exchanger and

Pump Module

2.5.4 Initial Inspection

When the equipment and accessories are received, they should be immediately

inspected for shortages and damage. If the equipment has been damaged in shipment or

shortages are noticed, immediately notify the carrier and file a claim.

Nominal Type M

Copper Tube or

Hose Size

Feet to Gallons Feet to Liters Meters to

Gallons

Meters to

Liters

1-1/4 inch (OD hose) 0.064 0.242 0.210 0.794

1½ inch (ID tube) 0.092 0.348 0.301 1.140

2 inch (ID tube) 0.163 0.618 0.535 2.027

2½ inch (ID tube) 0.255 0.965 0.837 3.167

42 mm (OD tube)

39.6 mm (ID tube)

0.099 0.375 0.325 1.232

54 mm (OD tube)

51.6 mm (ID tube)

0.168 0.637 0.552 2.091

66.7 mm (OD tube)

64.3 mm (ID tube)

0.261 0.990 0.858 3.247

Loading...

Loading...