● When connecting the indoor and outdoor units, seal the pipe after the welding

break exceeds 15 minutes to prevent dust and water from entering the pipe.

● To avoid burning the bottom panel, top panel, side panel, internal components,

other pipes, thermal insulation foam, power cables, and labels, take protective

measures, such as spreading a piece of wet cloth, around the welding position.

● During and after the welding, avoid exposing the refrigerant pipe for over 15

minutes because this may

inuence the system reliability.

● Take appropriate sealing and protective measures when routing welded pipes

through holes to prevent air channel leaks and copper pipe damage. Otherwise,

other components may be damaged by impurities.

● Avoid elbows and ensure that the connection between the indoor and outdoor

units is the shortest.

● The refrigerant pipe should be wrapped with thermal insulation foam.

● When a low-temperature outdoor unit is

congured, the stop valve of the

indoor unit should be wrapped with thermal insulation foam.

Procedure

Step 1 Route pipes based on the engineering requirements and weld pipes in the medium

segment by referring to Figure 4-57.

Exercise caution during welding to avoid burning components, such as rubber

rings, inside the cabinet.

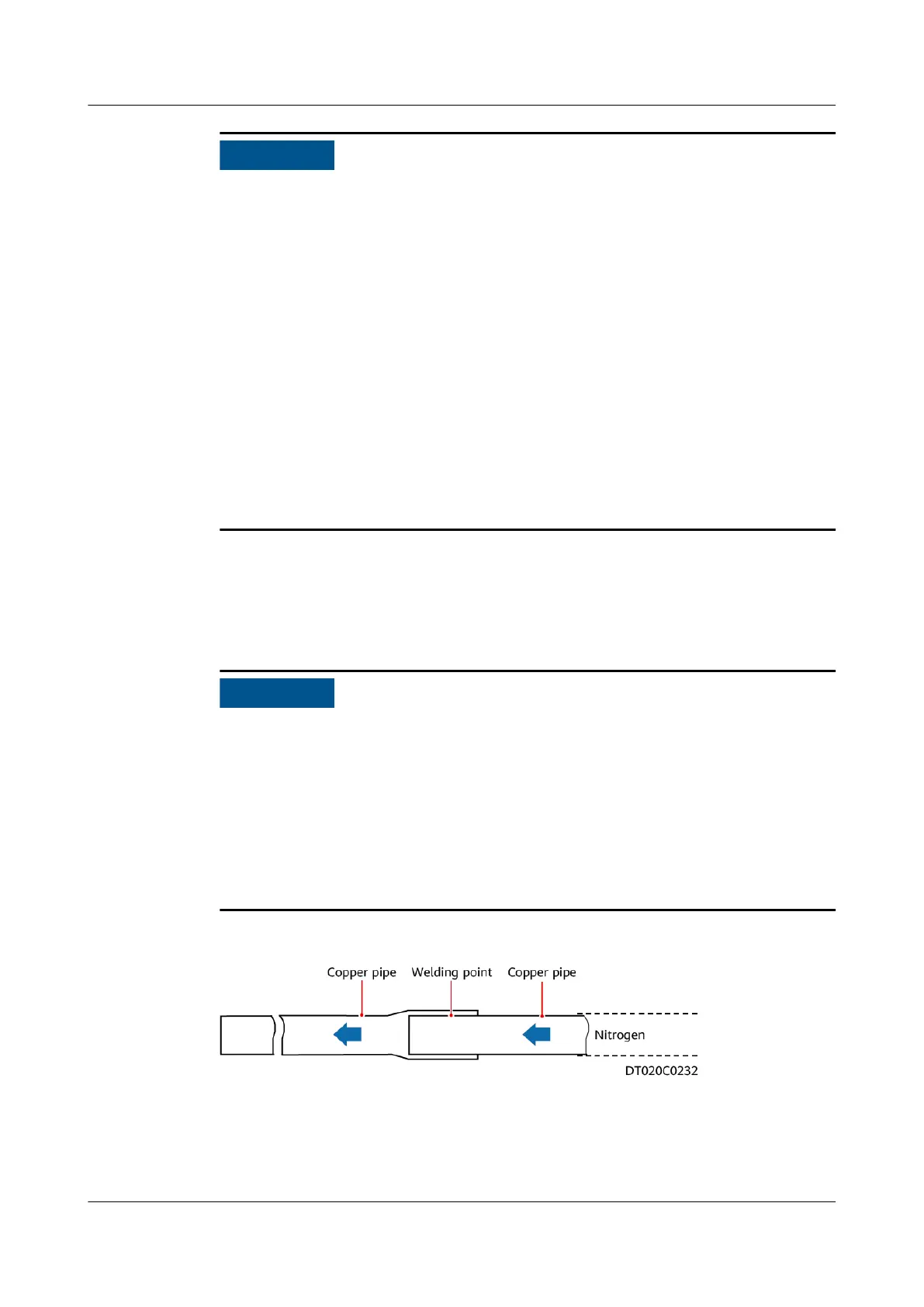

During the welding, charge a little nitrogen into the pipes to avoid internal

oxidation, as shown in Figure 4-56.

● When welding a gas pipe, gently inject nitrogen into the pipe at the gas pipe

needle valve.

● When welding a liquid pipe, gently inject nitrogen into the pipe at the liquid

pipe needle valve.

Figure 4-56 Welding pipes

● When the direction of the refrigerant pipe is changed, add a support at the

position that is 500 mm away from the changing point.

● If the refrigerant pipe is straight, add a support every 1500 mm.

FusionModule800 Smart Small Data Center

User Manual 4 Installation Guide

Issue 01 (2021-02-05) Copyright © Huawei Technologies Co., Ltd. 136

Loading...

Loading...