2. Installation

2.3.2 Installation of the Main Unit

The surface to mount the main unit should be a machined surface or a plane that possesses an

equivalent accuracy and the flatness should be within 0.05mm/m. Also, the platform should have a

structure stiff enough to install the unit so it would not generate vibration or other abnormality.

Also consider enough space necessary for maintenance work such as actuator replacement and

inspection.

T-slots are provided on the back of the actuator.

Nut holes are provided on the actuator frame front and the side-mounted motor type rear bracket.

Using these parts, the following installations can be realized.

· Installation by using T-slots

· Installation by using foot brackets (option: model FT)

· Installing main unit frame front

· Installation by using flange (option: model FL)

· Installation by using rear bracket for side-mounted motor types

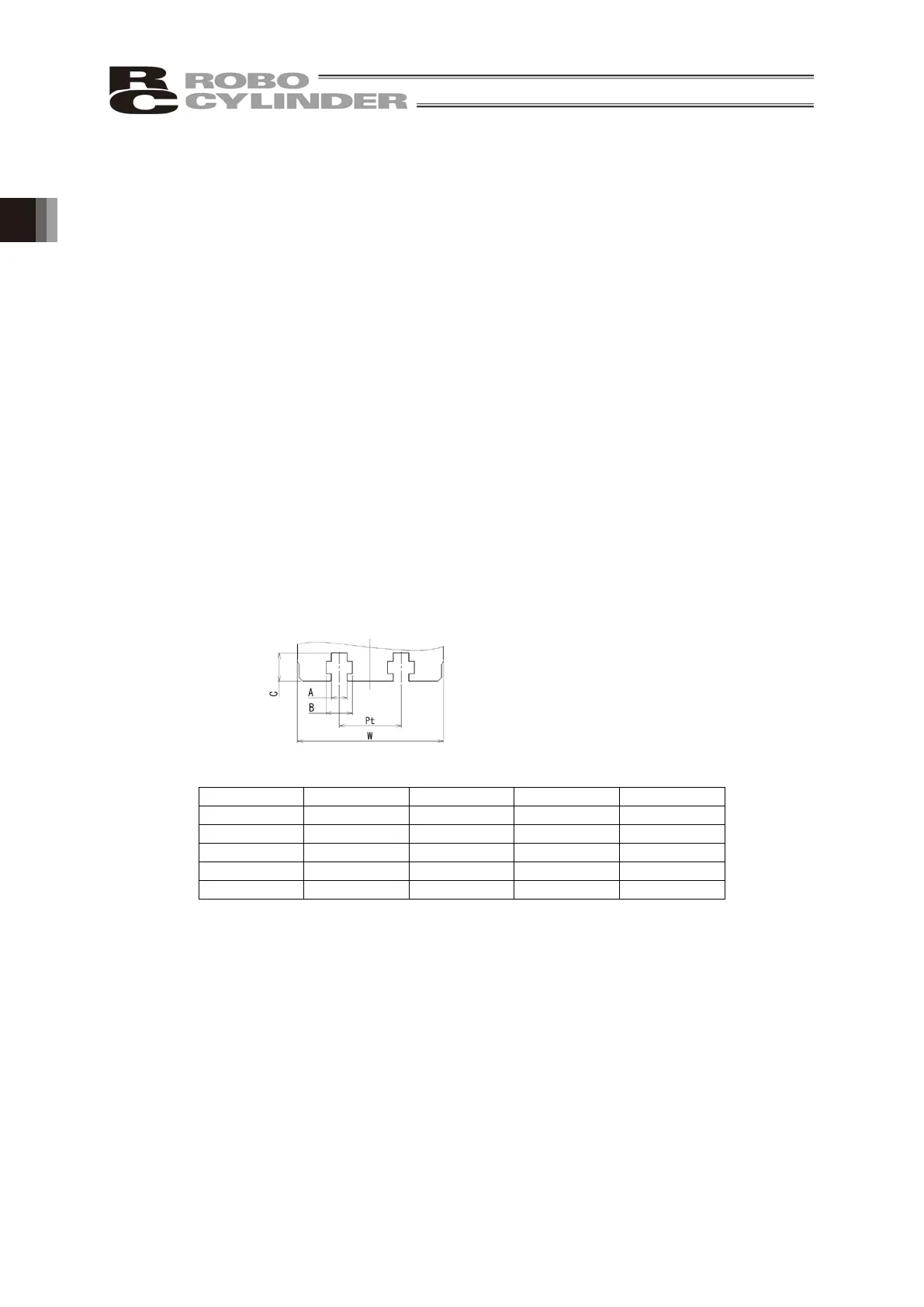

[1] Using the T-slot on the Bottom of the Base

This actuator has T-slot for mounting so it can be fixed from the bottom of the base.

There are two methods of installation: using square T-nuts into T-slots or using optional T-slot nut

bars (model: NTB).

(1) T-slots Dimensions

Loading...

Loading...