Goodrive300-01A-RT series integrated machine Commissioning instruction

-23-

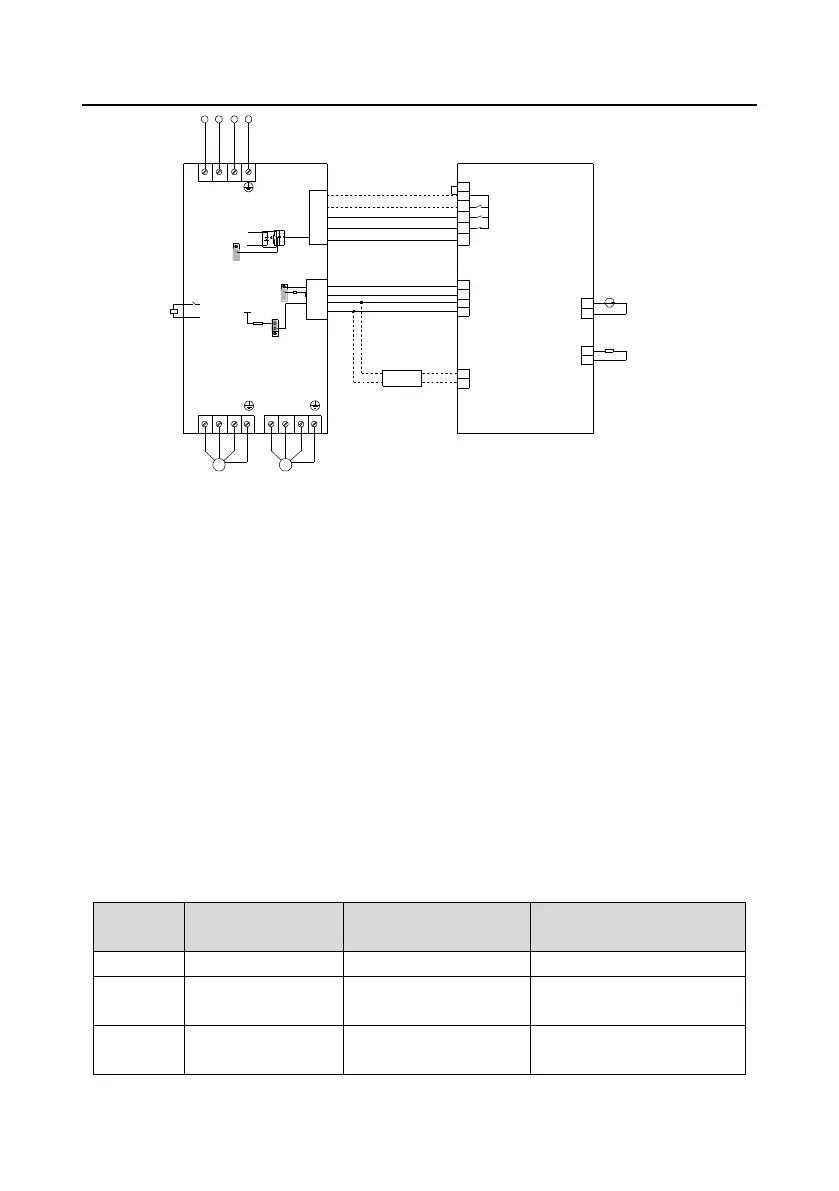

A2

B2

26

25

2

1

PT100

31

30

23

22

Temperature sensor

Pressure

sensor

220AC

Fan

MM

Main motor

U

1

Solenoid

valve

TC1

TA1

R

B1

A1

+24V

OUT

+24V

J7

+24V

CME

COM

J3

ON

J2

48 5-

48 5+

14

6

VFD fault output

W

2

V

2

U

2

W

1

V

1

S3

Y

48 5-

48 5+

GN D

+2 4V

Solenoid valve control

IoT module

S

T

S1

S2

MAM6080M

Fan start/stop control

CO M

12

VFD terminal start/stop

13

18

11

GD300-01A-RT

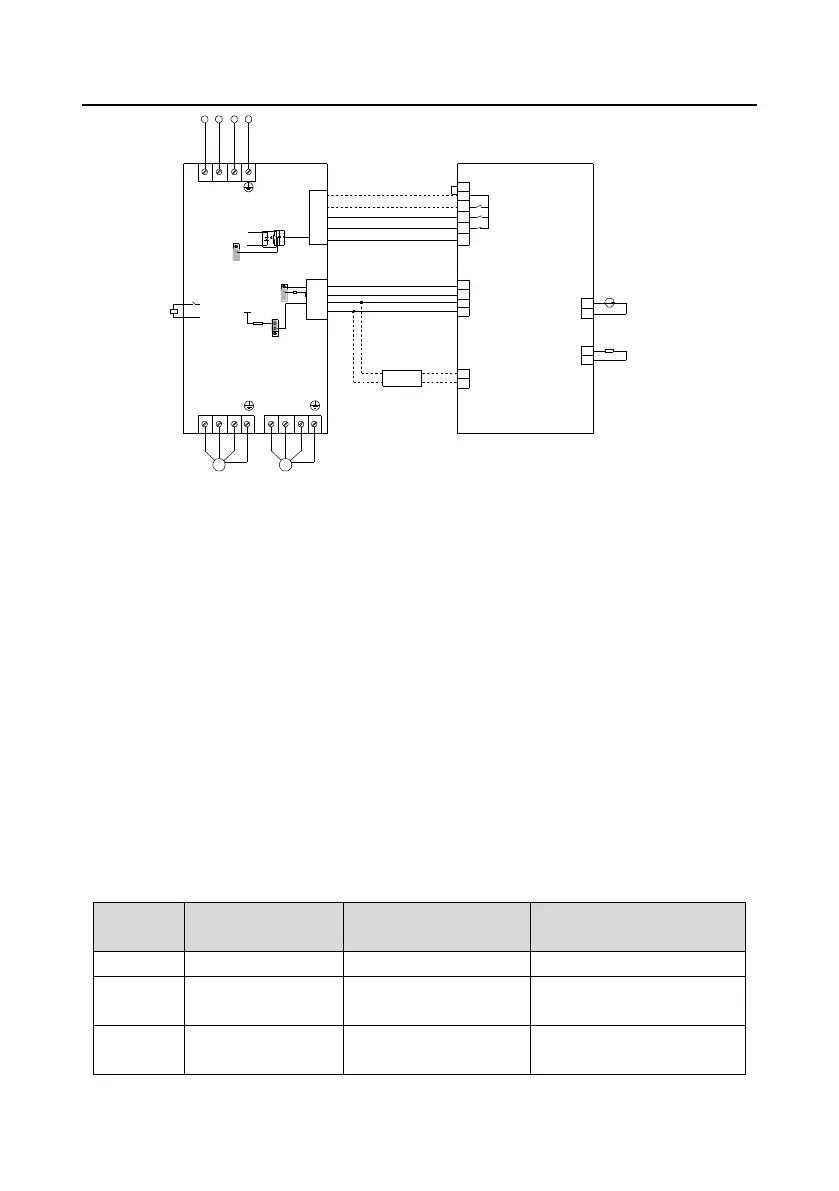

Figure 4-14 Wiring diagram for Plot controller 6080M + GD300-01A-RT VFD

4.2.2 Commissioning steps

Goodrive300-01A-RT series VFD can be used with Plot controller. The commissioning procedures

are as follows.

1. Perform wiring according to the wiring diagram based on onsite needs. Generally, start and stop

the master in communication control. It is recommended to use the terminal to control start and stop

of the main motor when the interference on the sire is strong. To start and stop the main motor in

terminal control, it is necessary to connect COM to S1 in accordance with the dotted line, ensure that

the VFD and air compressor shell are grounded.

2. Set jumpers according to Figure 4-13. Set P06.01=5, set the calibration parameter of Plot controller

(Phase sequence protection value) to 0 and block Phase sequence error 1, as shown in Figure

4-20. Set the hardware parameter of Plot controller pin 6 to Main motor VFD fault NO, as shown in

Figure 4-19. After these parameters are set completely, main motor VFD fault output is available.

3. Set P00.18=1 to restore to default value, and configure the system parameters sequentially

according to Table 4-1.

Table 4-1 System parameter configuration

Upper limit of

running frequency

P00.05–P00.03 (max. output

frequency)

Loading...

Loading...