Maintenance

Maintenance Schedules

Maintenance Schedules

General

WARNING Maintenance must be done only by suitably qualified and competent persons.

Before doing any maintenance make sure the machine is safe, it must be correctly parked on solid, level

ground.

To prevent anyone starting the machine, remove the key. Disconnect the battery (by means of the battery

isolator if installed) when you are not using electrical power. If you do not take these precautions you could

be killed or injured.

A badly maintained machine is a danger to the operator and the people working around the operator. Make

sure that the regular maintenance and lubrication tasks listed in the service schedules are done to keep the

machine in a safe and efficient working condition.

Apart from the daily tasks, the schedules are based on time. Keep a regular check on the hourmeter readings

to monitor the hourmeter equivalents. When there is no hourmeter installed, use the calendar equivalents to

determine the service intervals.

Do not use a machine which is due for a service. Make sure any defects found during the regular maintenance

checks are corrected immediately.

How to Use the Maintenance Schedules

The schedules show the service tasks which must be done and their intervals.

The services must be done at either the hourly interval or the calendar equivalent, whichever occurs first.

The intervals given in the schedules must not be exceeded. If the machine is operated under severe conditions

(high temperature, dust, water, etc.) shorten the intervals.

Table 9.

Service task can be completed by a competent operator. Details of how to com-

plete the service task are given in the Operator's Manual.

We recommend that a Service Engineer completes the service task. Details of

how to complete the service task are given in the Service Manual.

Maintenance Intervals

Table 10.

Interval ( h) Calendar Equivalent

10 Daily

50 Weekly

500 Six months

1000 Yearly

2000 Two Years

5000 Five Years

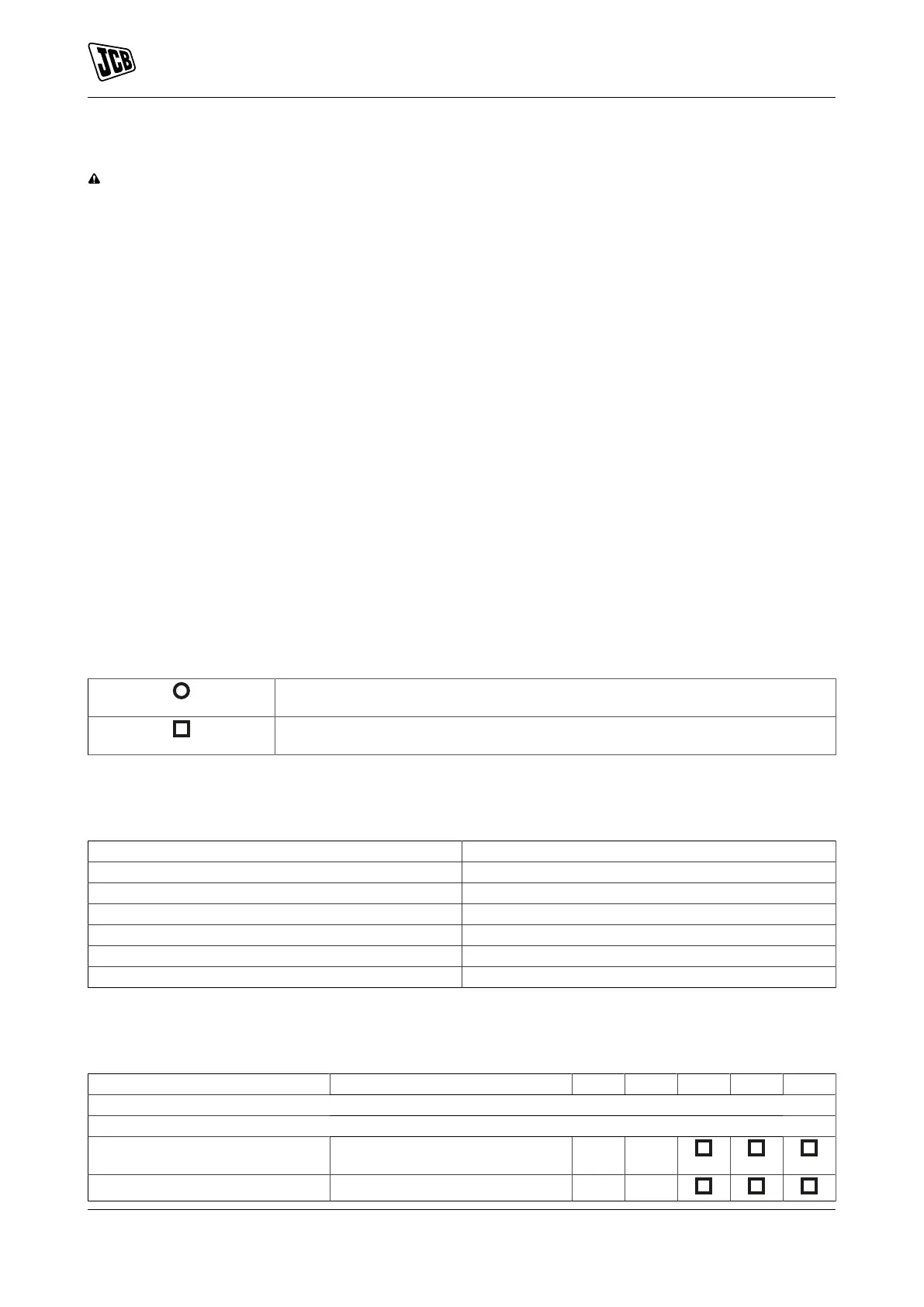

Pre-start Cold Checks, Service Points and Fluid Levels

Table 11.

Component Task 10 50 500 1,000 2,000

TRANSMISSION

Security of Mounting Bolts and Nuts

Track Wheel Motor to Undercar-

riage Bolts

Check

Drive Sprocket Bolts Check

112 9831/8250-4 112

JCB © Admin Pimteam - 23/06/2021 05:32.

Loading...

Loading...