Operation

Moving a Disabled Machine

Moving a Disabled Machine

General

If the machine becomes disabled, the machine must be made safe, placed onto a transporter and moved to

a location where it can be repaired.

You must contact your nearest JCB dealer before you try to tow, winch or push the machine.

Towing, winching or pushing the machine without following the correct procedure will damage parts of the

hydraulic system. If possible, repair the disabled machine where it stands.

Getting the Machine Unstuck

You can use the following methods to get the machine unstuck:

• Rock the machine forwards and backwards using drive

• Use the dig end to lift the undercarriage

• Position steel boards in front of the tracks

Retrieval

Notice: It is not recommended to tow a disabled machine. Permanent damage to the track motors of the

disabled machine may occur if the machine is towed.

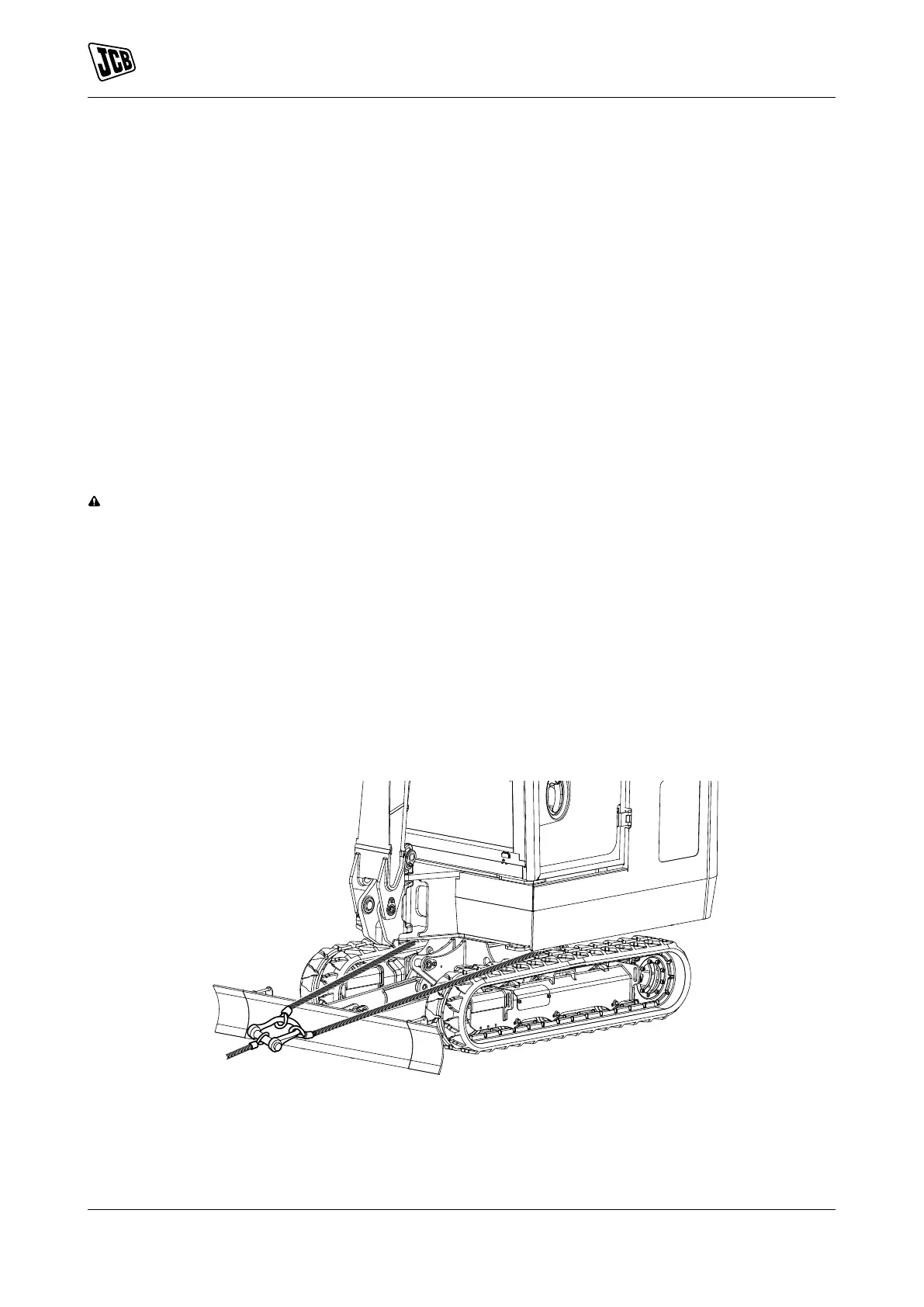

In the event that towing the machine to a safe location is unavoidable then fasten wire rope or chain capable

of pulling the machine around the slew ring as shown. Refer to Figure 55.

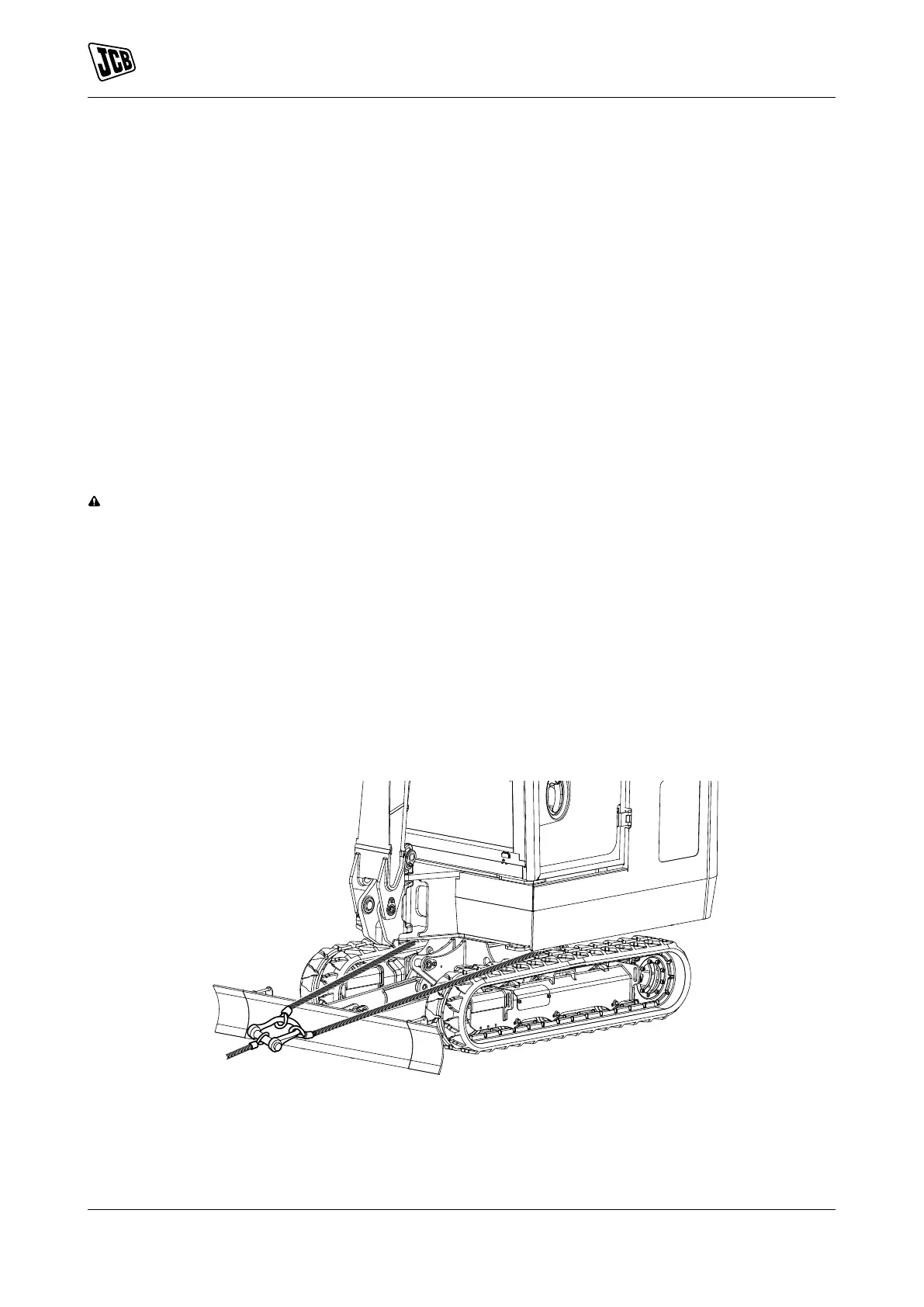

Wire rope or chain can also be fasten to the machine for towing in the alternate way as shown. Refer to Figure

56.

Apply the minimum force to move the machine slowly (not greater than 2km/h (1.2mph) smoothly and without

shocks).

Tow the machine the minimum distance to a safe location for recovery by lifting (not to exceed 20m). Following

this procedure the machine must be inspected by a qualified person for damage to the track motors.

Figure 55.

70 9831/8250-4 70

JCB © Admin Pimteam - 23/06/2021 05:32.

Loading...

Loading...