Maintenance

Tracks

Tracks

General

Clean

1. Make the machine safe.

Refer to: Maintenance Position (Excavator End Lowered) (Page 116).

2. Park the machine on solid, level ground.

3. Lower the bucket to the ground.

4. Clean the tracks with water.

5. Track forwards or backwards to clean the remainder of the tracks.

6. Make the machine safe.

7. Examine the track, roller sprockets and idler wheels for damage or oil leaks. Replace any damaged parts.

If in doubt consult your JCB distributor.

Rubber

Check (Operation)

WARNING Recoil unit servicing must only be carried out by JCB dealers. You could be killed or injured if

you tamper with it.

Notice: Always make sure that the track tension measurement is not less than specified or severe strain

to the track will result.

Grease Track Tension

WARNING A raised and badly supported machine can fall on you. Position the machine on a firm, level

surface before raising one end. Ensure the other end is securely chocked. Do not rely solely on the machine

hydraulics or jacks to support the machine when working under it. Disconnect the battery, to prevent the

machine being started while you are beneath it.

1. Park the machine on solid, level ground.

2. Operate the tracks backwards and forwards several times.

3. Stop the machine after operating the tracks forwards.

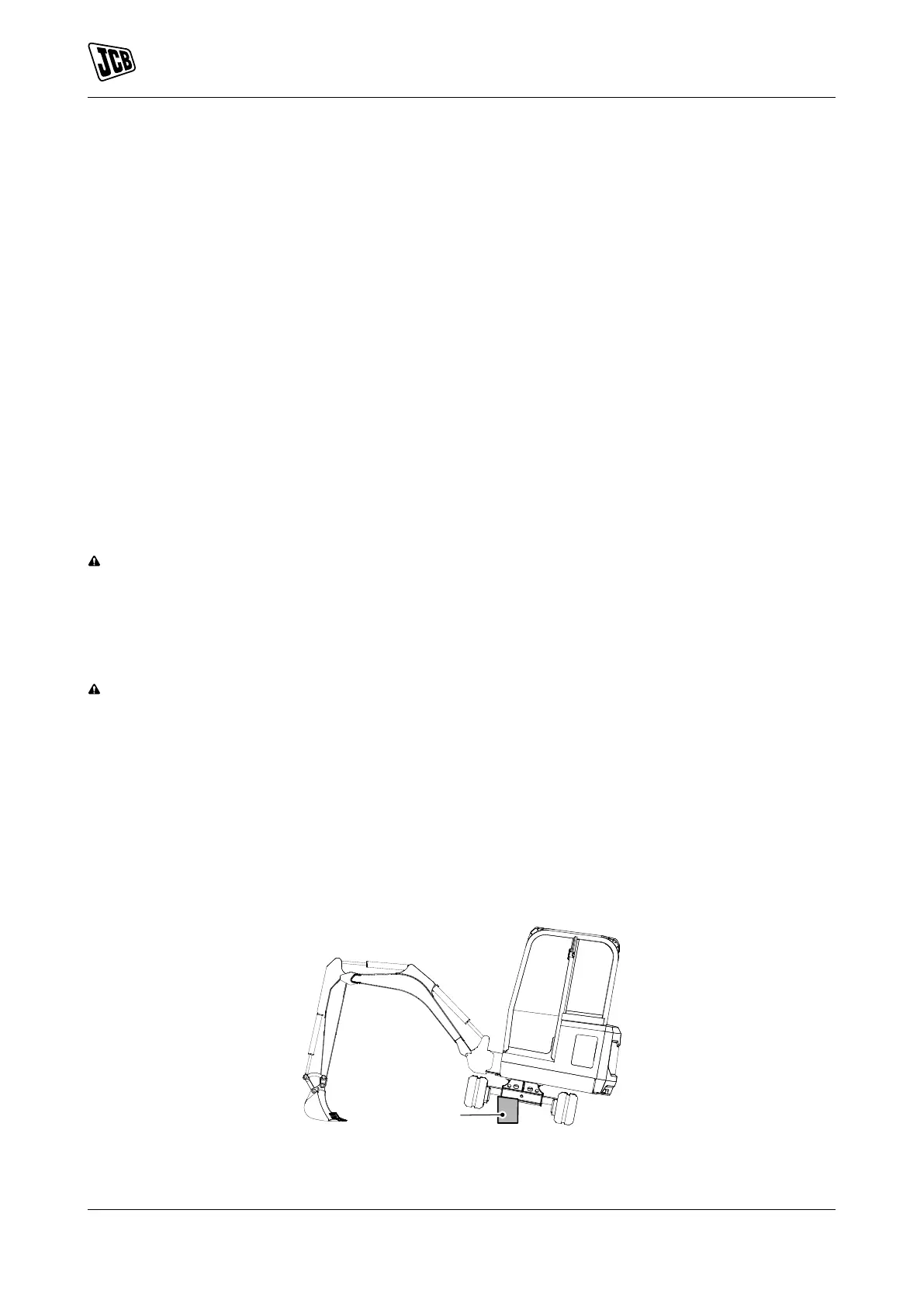

4. Set the machine in the posture shown with the track to be checked raised from the ground and supported.

Add a support under the machine.

Figure 104.

A Block

5. Check that the tension measurement is correct.

134 9831/8250-4 134

JCB © Admin Pimteam - 23/06/2021 05:32.

Loading...

Loading...