Unite

®

Panel System - Panel Frame Assembly

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

3

1

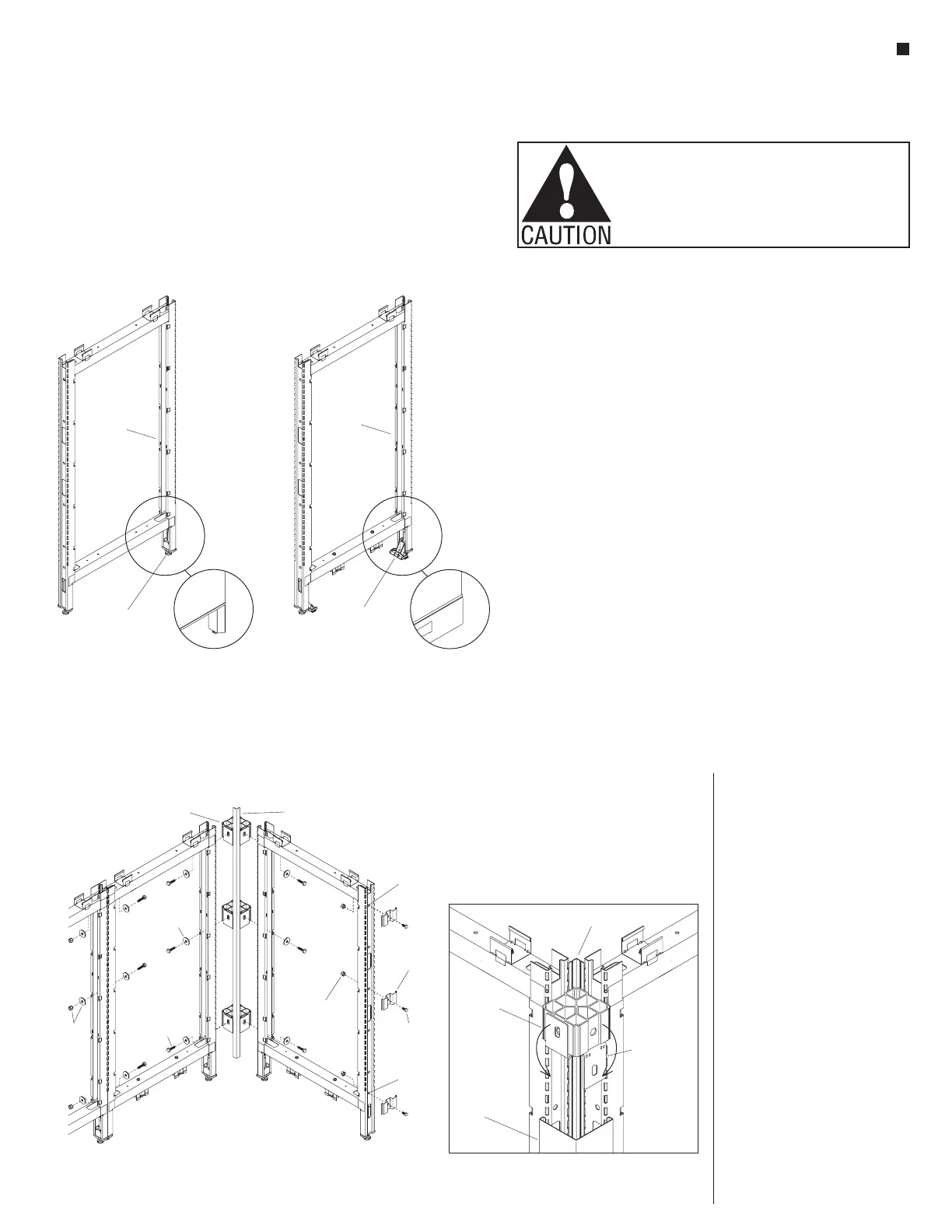

Elevated Base Frame Raceway Base Frame

height-adjustable

glide

base raceway

hinge clip

panel

frame

panel

frame

Panel Frame Overview

Note: If installing stacking sections

onto a pre-existing Unite Panel

System proceed to "Stacking

Sections - Overview" instructions on

page 67.

Unite Panel System frames ship

to the site as welded structures of

various heights and widths. Panel

frames easily connect to each other,

using a single size bolt/washer/nut.

Connections at intersections require

two or three connector blocks. Each

frame has two height-adjustable

glides pre-installed at the base of the

frame to help level the panel system.

The frame assembly becomes the

structure for attaching tiles, trim,

power/data components, storage

and many other accessories.

Your space-planning layout outlines

the panel type, and configuration.

This installation manual instructs

how to assemble the Unite Panel

components into a panel system.

Unite Panel System uses two panel

frame designs, the “Elevated Base

Frame” and the “Raceway Base

Frame” (Figure 1). Assembled and

installed, the Elevated Base Frames

have a 6” opening under the lower

horizontal rail, between the vertical

posts. Raceway Base Frames have

brackets installed under the lower

horizontal rail. Brackets are used for

mounting 10-wire rigid wireways

and base raceway trim to the frames.

Raceway trim fill the 6” opening to

the floor and allow for power and

data outlets.

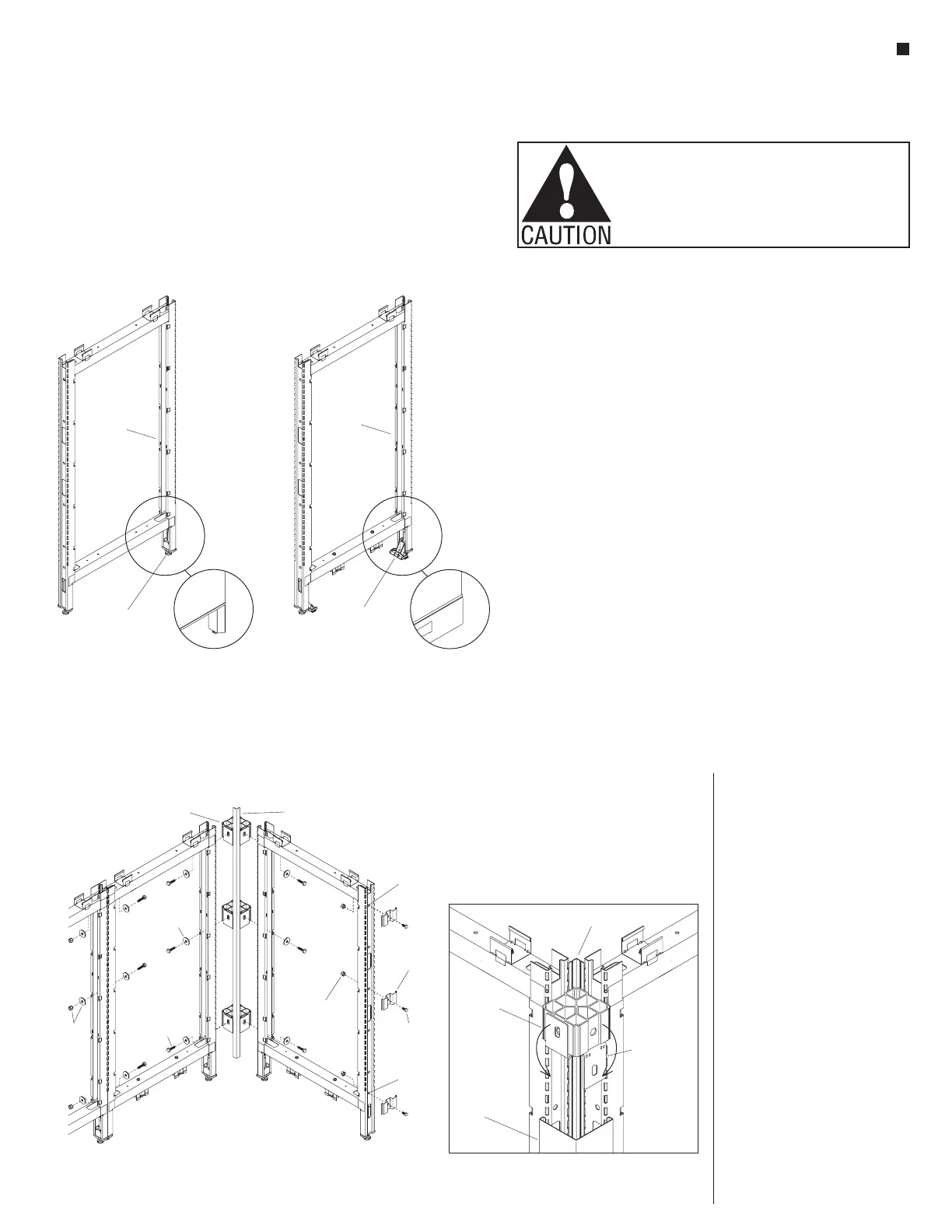

Intersection Connection

Overview

For simplicity, all Unite frame

intersections are secured using one

bolt size:

3

/

8

-16 x 1

1

/

4

” hex head

bolt (48.0115). All intersection

connections use this same bolt. A

3

/

8

-16 k-lock nut and flat washer is

used in some situations (Figure 2).

Connector Block with Spacer

Plate Overview

All intersection and some in-line

intersections require the use of

connector blocks. Connector blocks

attach to the panel frame using a

single

3

/

8

-16 x 1

1

/

4

” hex head bolt

(48-0115) and a flat washer.

Important: Connector blocks are

now pre-assembled with spacer

plates at each of the four faces.

When attaching the connector block

to a frame, it is important that the

spacer plate be left in the “up”

position. The spacer plates maintain

the 3

1

/

2

” standard modularity of the

Unite panel system. When installing

trim, the spacer plates must be bent

straight “down” so the trim can sit

flush with the connector block.

Reconguration: If an intersection

must be reconfigured; the spacer

plate can be lifted “up” and returned

flush with the connector block.

End-of-Run Clips Overview

Trim, installed at the end of frames,

connect to end-of-run trim clips

which must be installed prior to

installing tiles. End-of-run trim clips

attach to frame ends using a single

3

/

8

-16 x

3

/

4

” hex head bolt and

3

/

8

-16

K-Lock nut per clip (Figure 2).

Figure 2-Parts Identification

connector

block

shield

uppermost

hole

flat

washer

lowest

hole

end-of-run

trim clip

/ -16 x /

bolt

8

4

”

3

/ -16

k-lock nut

8

31

/ -16 x 1 /

bolt

84

”

k-lock

nut

and

flat

trim

connector

block

spacer plate

(must be pulled

down when

attaching to

trim)

light shield

Loading...

Loading...