8

Unite

®

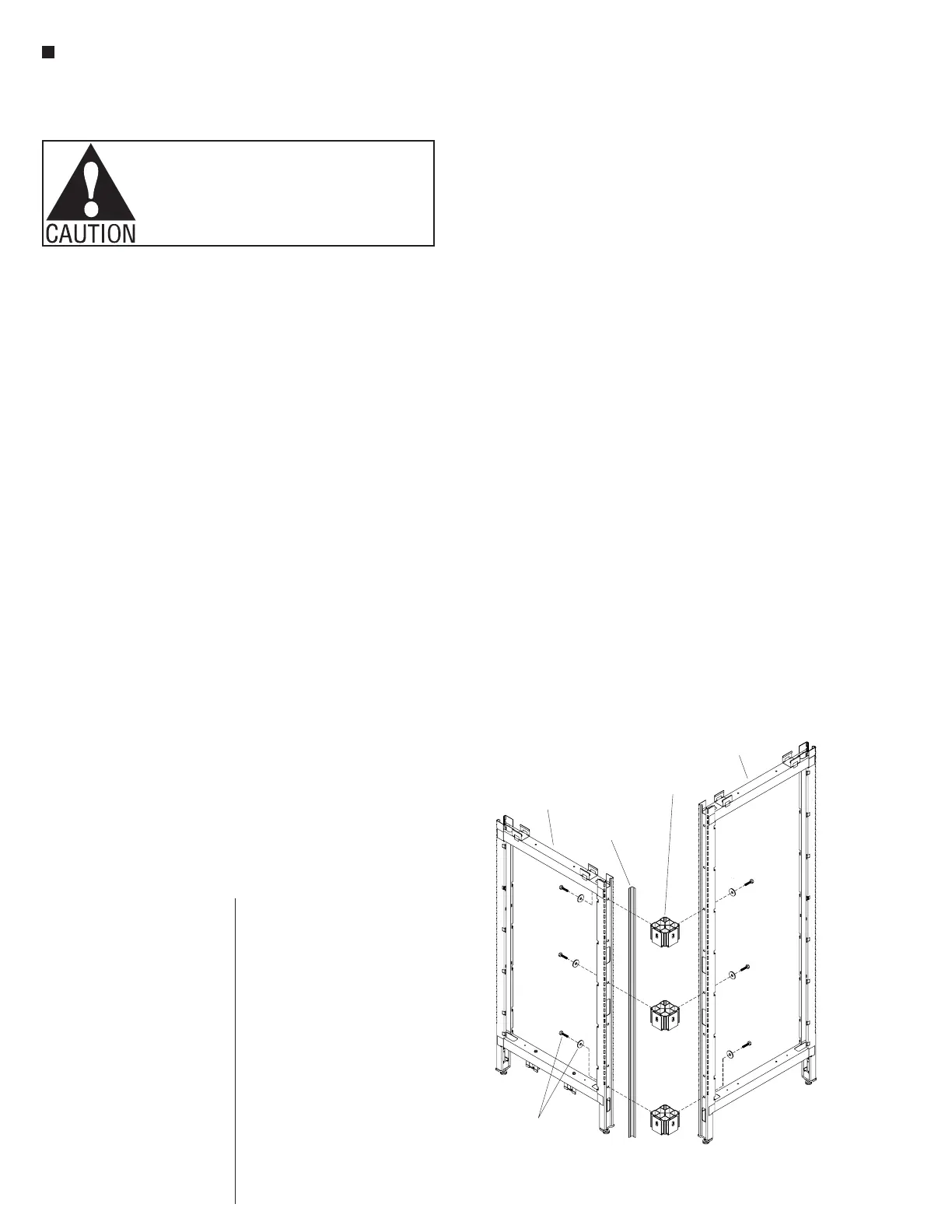

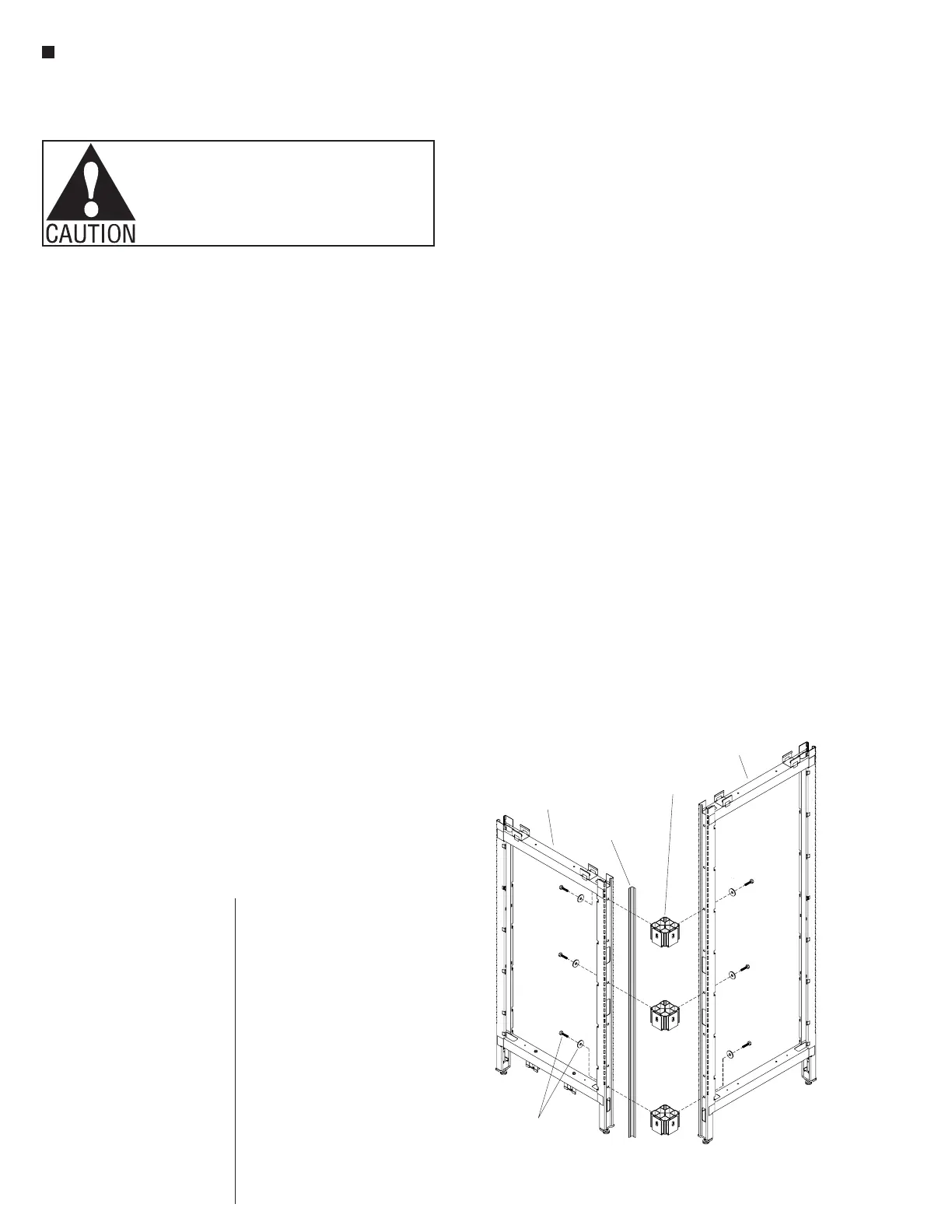

Panel System - Panel Frame Assembly

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

light

shield

panel frame

(taller)

panel frame

(shorter)

8-2-Way90,Change-of-Height “L” Corner

°

31

/ -16 x 1 /

bolt & flat washer

84

”

connector

block

Panel Frames - Change-of-

Height Intersection Assembly

1. Per the space-planning layout,

locate the two change-of-height

panel frames to be joined

together. Begin first with the

shorter panel frame as the

shortest panel determines the

number of connector blocks

required (Figure 8).

2. Loosely attach connector blocks

to the shorter panel frame, as

illustrated using one

3

/

8

-16 x 1

1

/

4

”

hex head bolt and large flat

washer per connector block.

Attach one connector block at

the lowest mounting hole in the

frame, one block at the highest,

and the third connector block

approximately 30” from the floor,

near beltway height (Figure 8).

Note: If the panel frame is only

32” high, use only two connector

blocks, one at the top and one at

the bottom (See Panel Connector

Block Chart, page 5).

3. Have one person hold the shorter

panel frame (with connector

blocks and light shield attached)

while another person attaches the

taller panel frame to the mating

face of the connector blocks

using hex head bolts and flat

washers. Hand-tighten hardware

at this time (Figure 8).

4. Level each panel frame at the

intersection and tighten all hex

bolts.

Note: Light shields are available

in 48, 64 & 80” nominal lengths.

The above light shield lengths do

not require cutting when paired

with the same nominal height

panel frame.

5. Begin light shield installation by

first locating the nominal length

plastic light shield that matches

the nominal height panel frame it

installs adjacent to. For nominal

height 32, 40 & 56” panels,

locate a light shield that is longer

than, but closest to the nominal

frame height. When required

(for 32, 40 & 56” panel heights),

cut the longer plastic light shield

to size. See Detail A - “Light

Shield Table,” page 5 to

determine proper cut length.

6. Plastic light shields must be

installed after intersections are

assembled and all bolts are

tightened into connector blocks.

Measure and make a mark that

is

5

/

16

” down from the top of the

vertical frame post (Detail B,

page 5). Using the proper length

light shield, position the top of

the shield at that

5

/

16

” mark. Snap

the light shield into the corner of

each connector block such that

you hear a “click”, ensuring that

the light shield is snug at each

connector block.

Note: The bottom of the light

shield should fit flush with

the bottom trim when trim is

installed. The top of the light

shield should fit nearly flush with

the underside of an intersection

top cap when it is installed later.

Tip: A top cap can be temporarily

installed to help locate the top

of the light shield. Snap the light

shield in place such that the top

of the shield is flush with the

bottom of an installed top cap.

Loading...

Loading...