Unite

®

Panel System - Electrical Installation

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

33

11

/ -20 x 2 /

thread-forming

screw

44

”

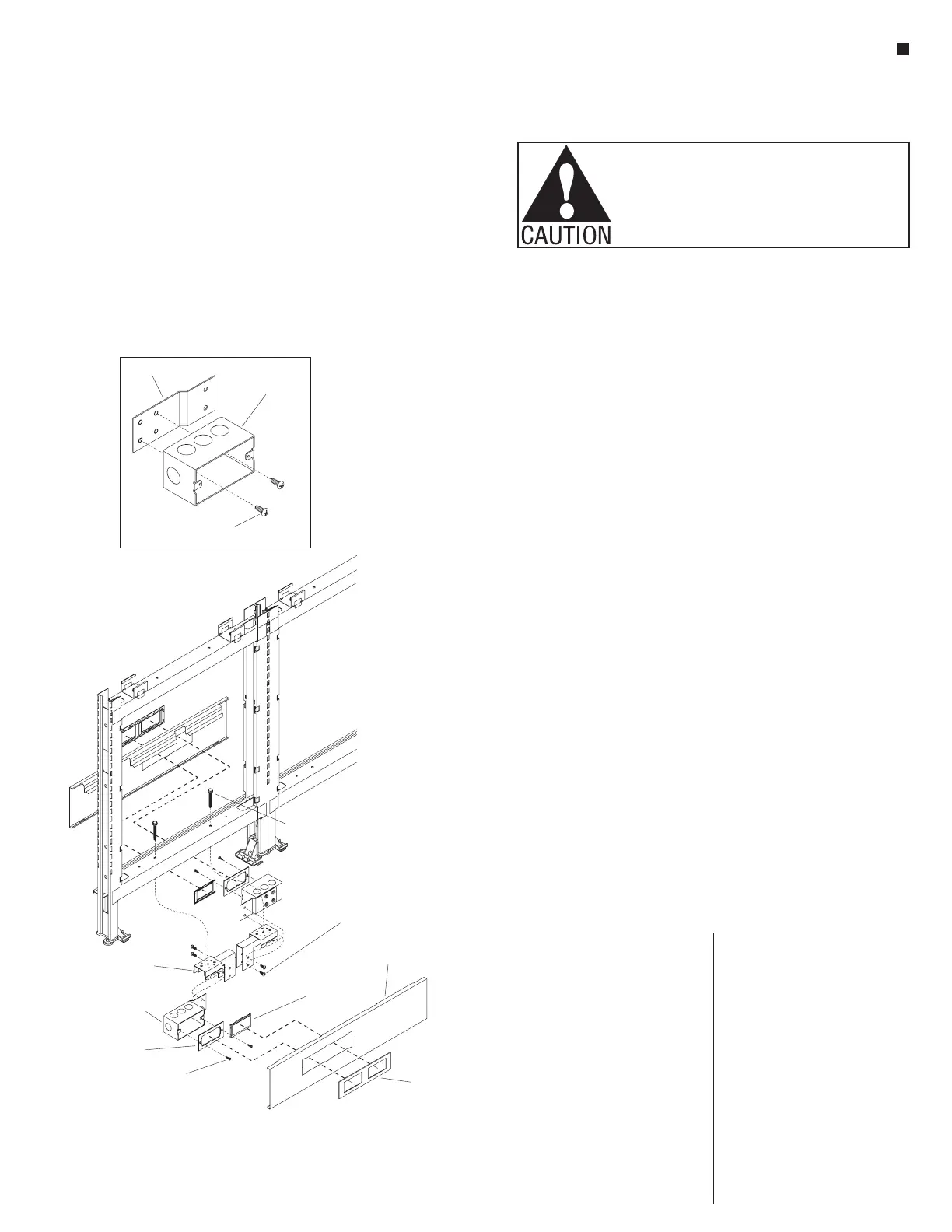

Figure 19-Chicago Hardwired Base Power Infeed - 24”&30” Panel

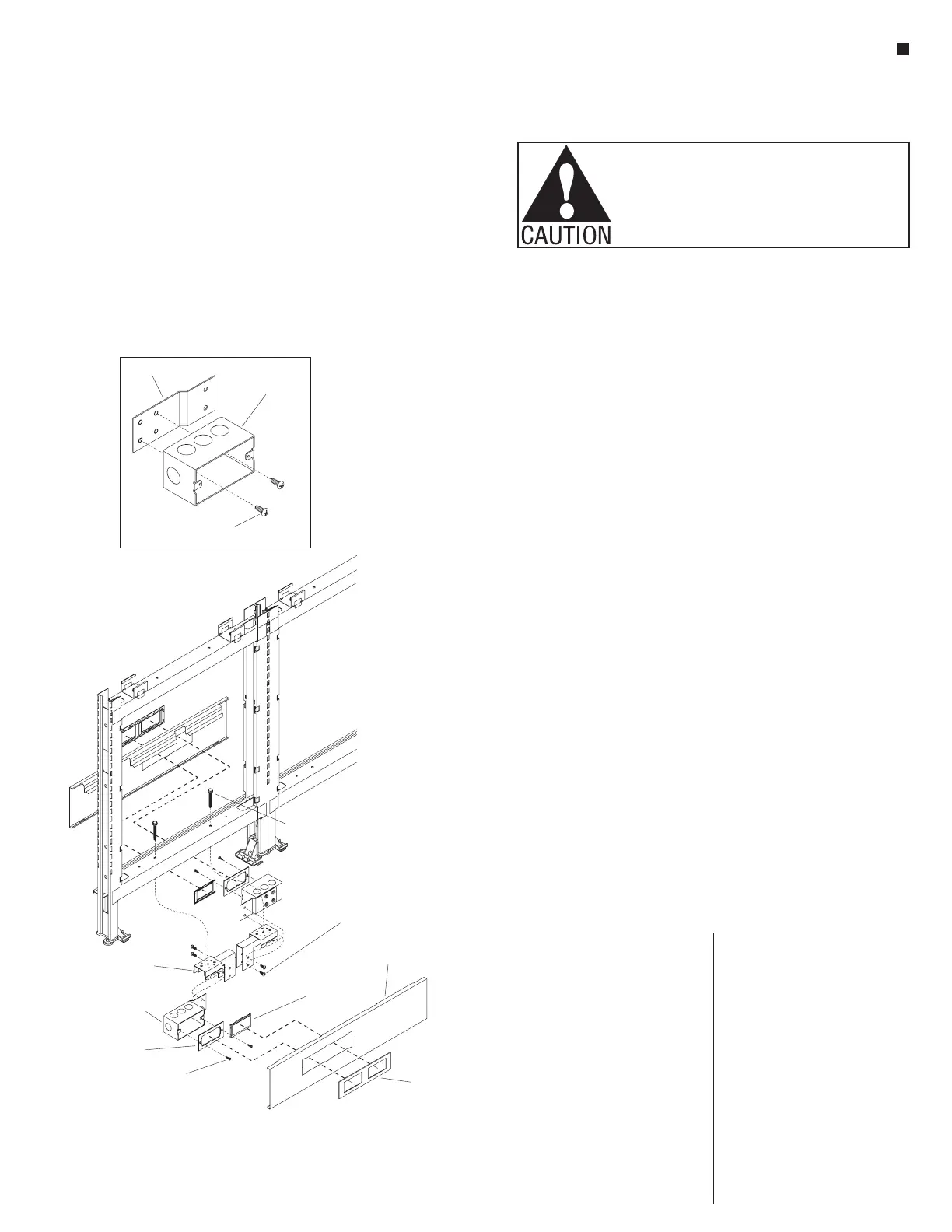

Detail L

receptacle box &

Chicago mounting

bracket

Chicago base

raceway cover

data filler

plate

Z-bracket

receptacle

box

Chicago

bezel plate

Chicago

filler plate

filter

plate screw

15

/ -20 x 2 /

Phillips thread-forming

screw (46.0195)

4

16

”

15

/ -20 x 2 /

Phillips thread-forming

screw (46.0195)

416

”

Chicago Hardwired Base Power

Infeed Installation - 24” & 30”

Panel Width

Important: All panel frames

must be mechanically connected

together, with all rigid wireways

and panel-to-panel power

connections appropriately

installed before adding power

infeed, or connecting infeed to

power source.

Note: The Chicago Hardwired

steel receptacle boxes may mount

to open at both sides of the frame

base, but the boxes are staggered

to not be back-to-back. Frames of

24” or 30” wide can accommodate

only one receptacle box per side,

while 36” through 72” wide frames

can accommodate two receptacle

boxes per side.

Chicago Hardwired - 24” & 30”

Panel Width

1. Position a Z-bracket to the back of

a steel receptacle box, and attach

bracket to box using two

1

/

4

-20 x

5

/

16

” Phillips

thread-forming screws (46.0195)

as illustrated (Detail L). Assemble

all remaining panel boxes and

Z-brackets together at this time.

The receptacle box & Z-bracket

assemblies are non-handed, so

can be used on either side of the

frame.

2. Using two

1

/

4

-20 x

5

/

16

” Phillips

thread-forming screws, attach

a Chicago mounting bracket to

each receptacle box & Z-bracket

assembly as illustrated. Orient the

parts for assembly such that the

screw goes through the Chicago

bracket and threads into the

Z-bracket (Figure 19).

3. If the lower panel frame rail has

two brackets mounted under

it, remove the

1

/

4

-20 x 2

1

/

4

”

thread-forming screws (46.0195)

securing them. Discard the

brackets but retain the

thread-forming screws. Orient the

Chicago mounting brackets (with

receptacle & Z-bracket attached)

under the holes in the lower panel

frame rail and secure the Chicago

mounting brackets to the frame

rail using a

1

/

4

-20 x 2

1

/

4

”

thread-forming screw (Figure 19).

Note: The power infeeds are to be

connected to the power source by

a qualified electrician who must

follow all state and local codes

at the building site and check the

electrical integrity of the finished

system.

4. Install conduit, wiring and

receptacles per Chicago Electrical

Codes.

5. Place a Chicago filler plate over

the receptacle box as illustrated

and secure with two filler plate

screws (Figure 19).

6. Install Chicago base raceway

covers in the same manner as

standard Unite. Chicago base

raceway covers are different

than standard as the cut-outs

are in unique locations for this

application (Figure 19).

7. Snap the Chicago bezel plate into

the Chicago base raceway cover.

Chicago bezel plates are different

than standard as they have the

1

/

2

”

deep snap tabs removed. Snap the

data filler plates into the Chicago

bezel plates if no data cables are

used at that location. The data port

accepts modular furniture data

port covers or data jacks

(Figure 19).

Loading...

Loading...