Unite

®

Panel System - Gallery Panel Installation

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

35

End-of-Run Dual-Sided &

Single-Sided Gallery Panel

Installation

Note: Sizes for high-pressure

laminate (HPL) and

thermally-fused laminate (TFL)

gallery panel models are unique

and different. However, both HPL

and TFL gallery panels install the

same. The following instructions

apply to both HPL and TFL

models. All end-of-run gallery

panels ship with an 11-gauge

steel plate which fastens to the

inside face of the gallery panel.

Glides are pre-installed at each

bottom corner of all gallery panels.

Note: The following instructions

assume the gallery panel is the

same height as the Unite panel

run. If there is a change-of-height

between gallery or Unite panel,

additional trim will be required.

Preparation: If the installation

is new, gallery panels should be

treated the same as Unite panel

frames, and must be installed prior

to tiles and trim. In some cases, the

gallery panel functions as a return

and may act as a support for a Unite

panel run.

If the installation is a retrofit or

add-on, then Unite tiles must be

removed from the end of the Unite

panel run and set aside. The bottom

tile channel and raceway trim can

remain in place.

In either case, the Unite panel

run must be installed and leveled

per standard Unite, panel frame

installation instructions.

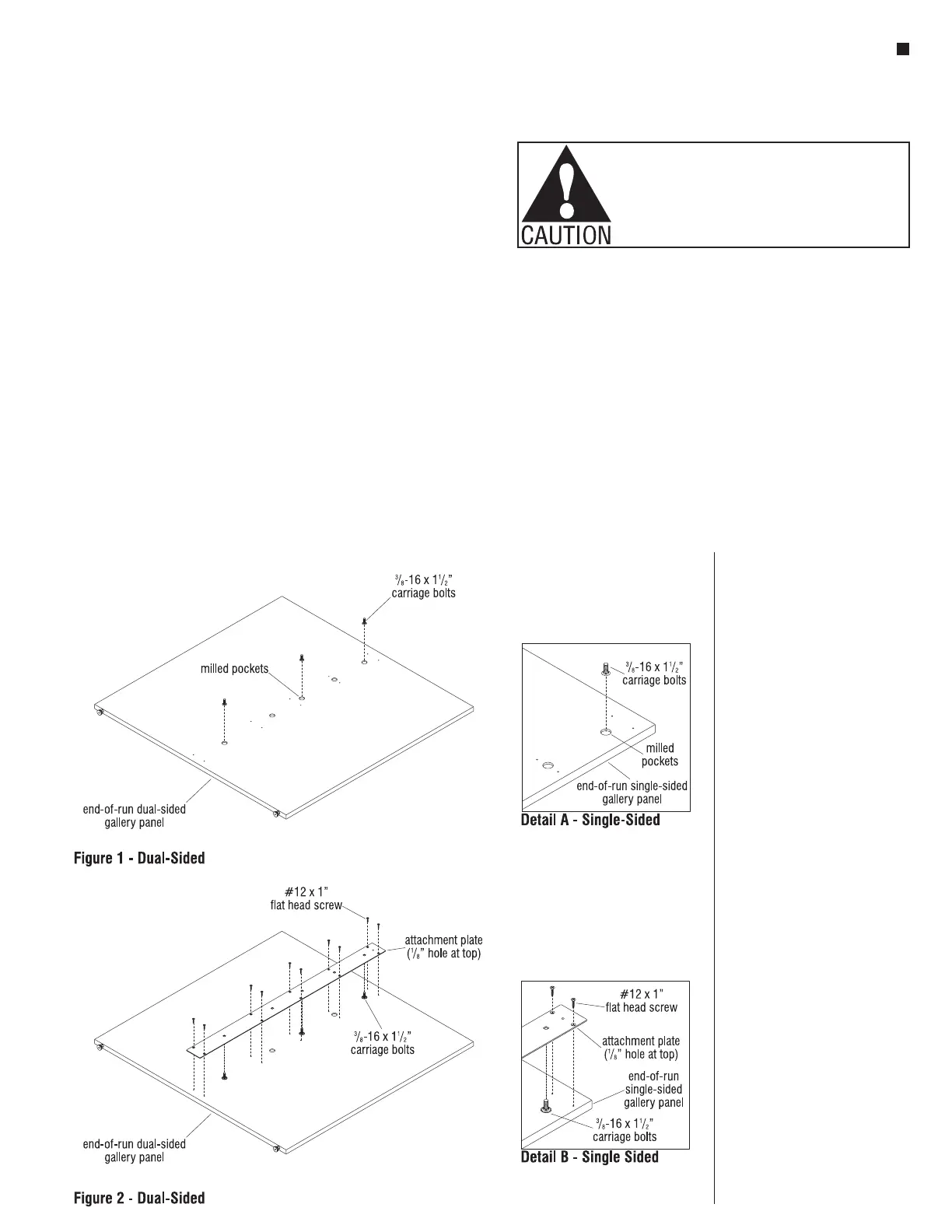

1. Lay the gallery panel onto a soft

protective surface on the floor

so the side with mounting holes

faces up. Place three

3

/

8

-16 x 1

1

/

2

” carriage bolts

loosely into the round, milled

pockets with the bolt head resting

in the pocket and the shank

pointing upward. Place one bolt

in the top hole, one in the lowest

hole and the third in any hole

near the middle of the panel as

illustrated. Not all holes will

receive bolts (Figure 1 &

Detail A).

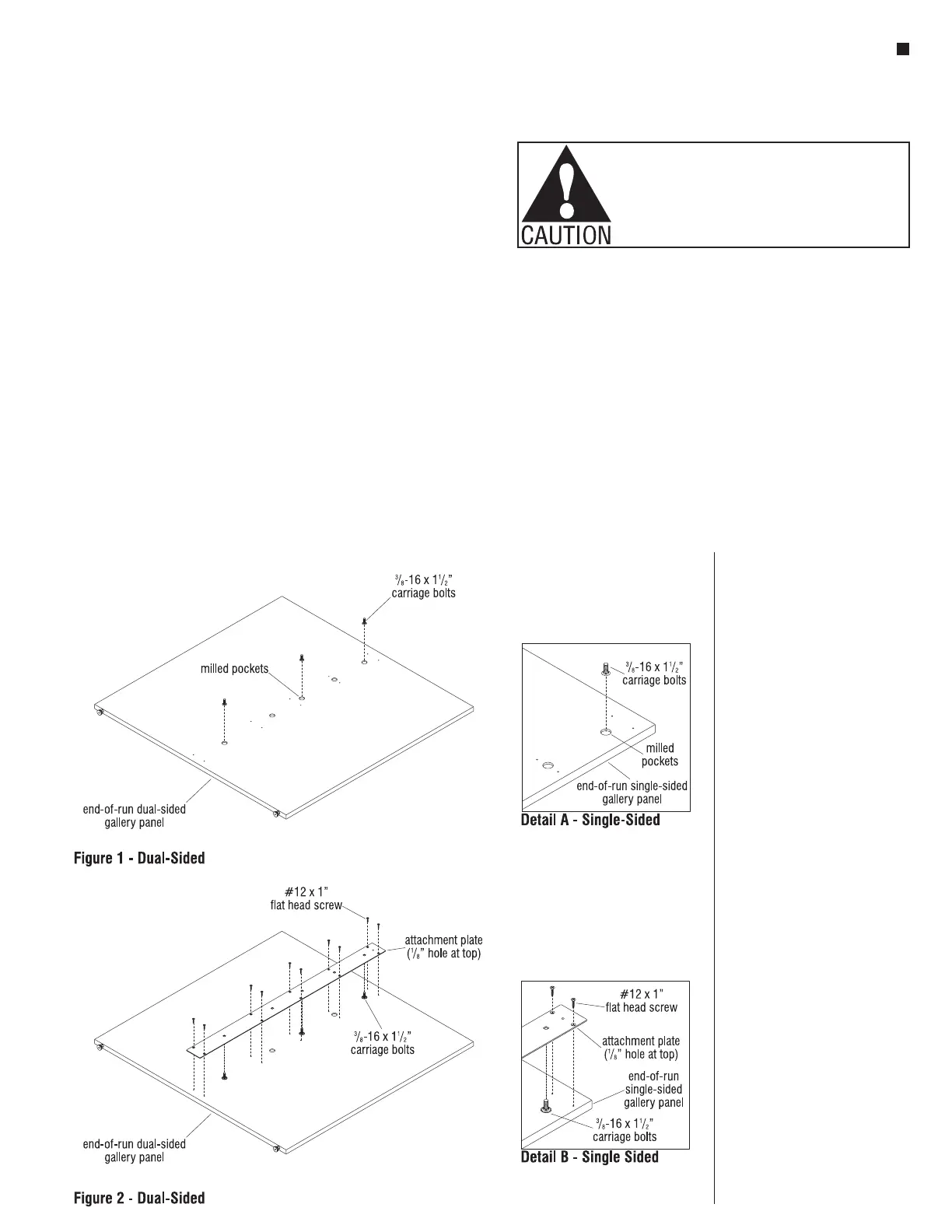

2. Locate the top of the 11-gauge

attachment plate. The top has

a

1

/

8

” hole at the center of the

plate to identify the top. Align the

top edge of the attachment plate

with the top of the gallery panel

(opposite the bottom glides) as

illustrated. Lay the plate down

and allow the three carriage bolts

to protrude through three square

holes in the plate (Figure 2 &

Detail B).

Caution: Make sure the

shoulders of the carriage bolt are

nested in each square pocket and

that the plate lays flush against

the face of the panel.

3. Install #12 x 1” flat head screws

into each counter-sunk hole as

illustrated. Each hole should

match up with a pre-drilled

1

/

8

”

diameter pilot hole in the panel.

Snug each screw tight (Figure 2

& Detail B).

Caution: Do not over-torque

screws which could strip the

threads in the particle board.

Loading...

Loading...