6

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

Unite

®

Panel System - Panel Frame Assembly

Assembly Instructions

uppermost

hole

lowest

hole

beltline

hole

31

/ -16 x 1 /

bolt & flat washer

84

”

panel

frame

120

connector

block

°

120

light

shield

°

glide

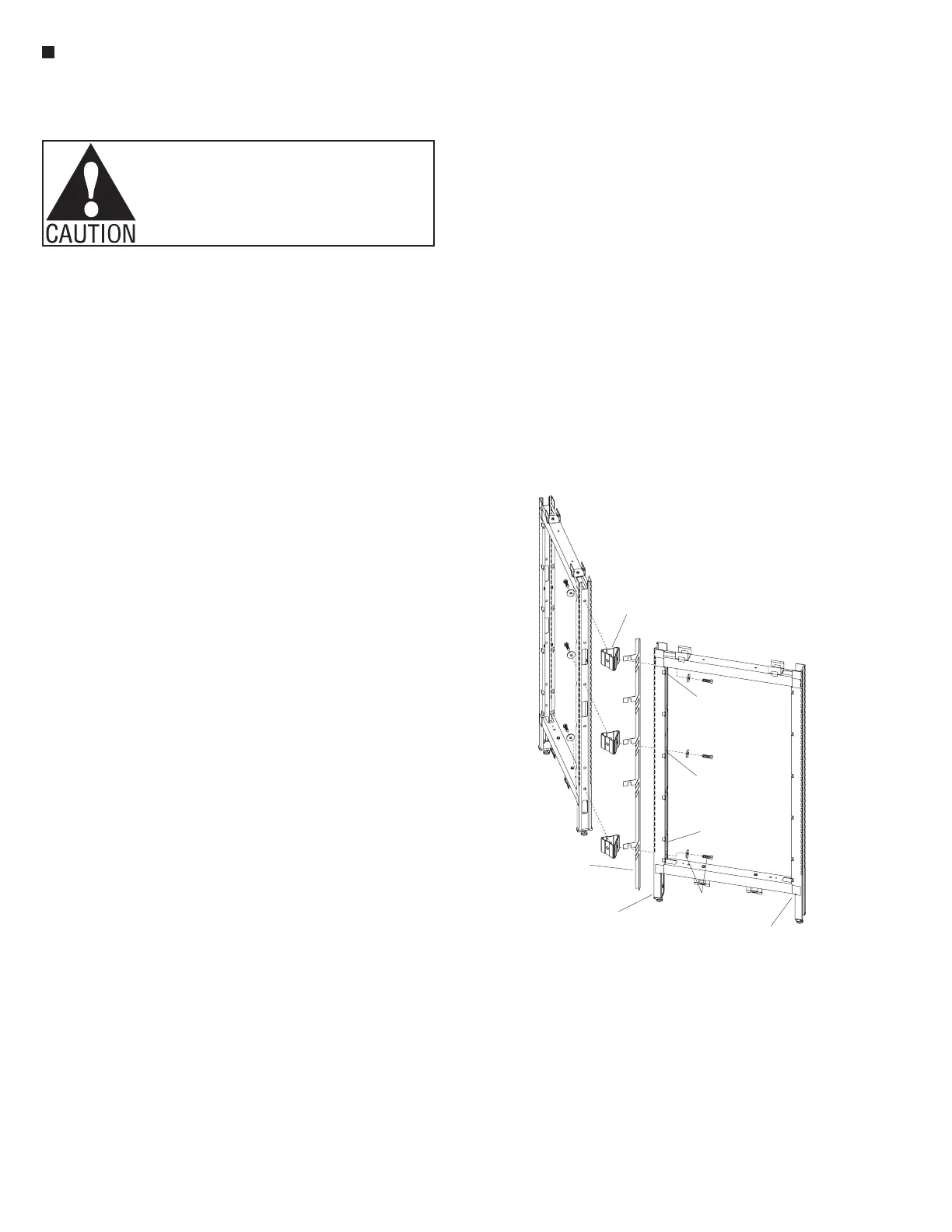

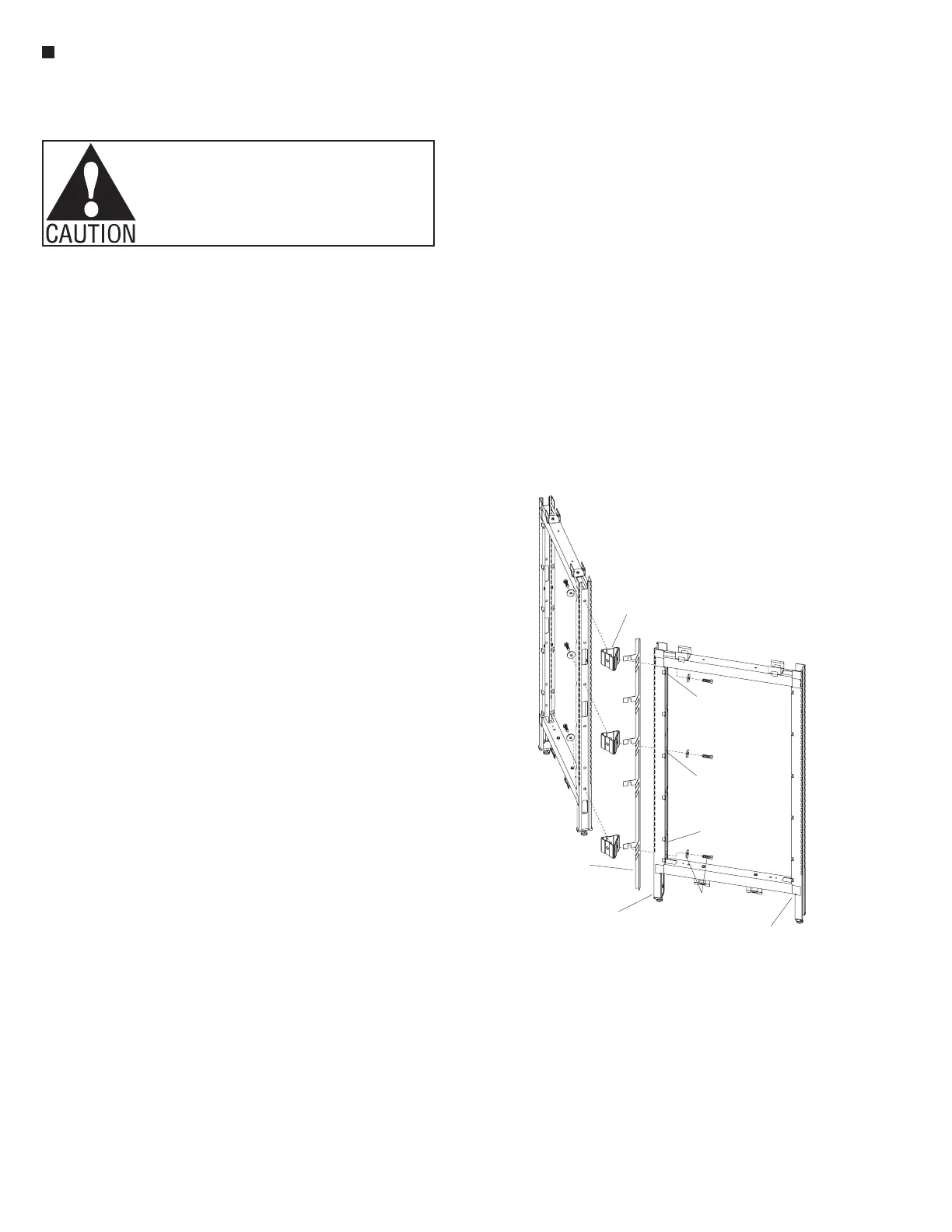

Figure 6 - 2-Way 120 , Corner Intersection

°

120º Panel Frames -

Intersection Assembly

Note: Assembly of 120º panel

frame intersections are similar

to 90º panel frame intersections,

except the design, function and

installation of the light shields

are different between the two.

As shown on pages 4 & 5, 90º

intersection light shields are

made of plastic and have no

tabs. The 120º intersection light

shields are made of metal and

have integral tabs which serve as

spacers for proper panel frame

spacing. Care must be taken

to install 120º intersections

correctly.

Important: It is very important

to level the panel system. Know

and mark all high and low spots

on the floor, and make sure to twist

adjustable glides out appropriate

to floor conditions. Always begin

assembling panels together at the

highest point of an un-even floor,

with the glides adjusted

1

/

2

” from

the base of the frame.

Note: The instructions to follow

outline the assembly of 120º

panel frame intersections using

panel frames of the same height.

Your configuration may vary.

Reference the appropriate 90º

intersections instructions if your

configuration varies. If a 120º

Change-of-Height Panel Frame

intersection is to be assembled,

reference "Panel Frame - Change-

of-Height Intersection Assembly"

instructions on page 8. If a 120º

stacking section (aluminum

frame) intersection is to be

assembled, reference "Stacking

Panel Sections (aluminum

frame) - Full-Height Intersection

Assembly" instructions on

page 9. If 120º stacking section

(steel frame) intersection is to be

assembled, reference "Stacking

Sections (steel frame) -

Full-Height Intersection Assembly"

instructions on page 10.

1. Loosely attach 120º connector

blocks and appropriate length

light shields to one vertical panel

frame using one

3

/

8

-16 x 1

1

/

4

” hex

head bolt and large flat washer

per connector block. Slide the

light shield over the mounting

bolts, between the panel frame

and the connector blocks

(Figures 6 & 7). Attach one

connector block at the lowest

mounting hole in the frame,

one at the highest, and the third

approximately 30” from the floor,

near beltway height. If the panel

frame is only 32” high, use only

two connector blocks, one at the

top and one at the bottom (See

Panel Connector Block Chart,

page 5).

2. Have one person hold the panel

frame (with 120º connector

blocks and light shield attached).

Then attach the next panel frame

and light shield to the first panel

frame using hex head bolts

and flat washers. Hand-tighten

hardware until all intersection

connections are made (Figures

6 & 7).

Note: Multiple frame

intersections require multiple

light shields. Work around the

intersection in a counter-clockwise

direction attaching panel frames/

light shields until all panels are

loosely attached. Light shields

slide in between the panel frame

and connector blocks and then

nest down onto mounting bolts.

This requires that the intersection

remains loose until all frames are

attached at an intersection.

4. Tighten all hex bolts at

intersections, then level the

panel frames, twisting the

height-adjustable glides in or out.

When tightening the bolts, ensure

that all intersection light shields

are properly in place and fully

engaged around the bolt shaft

(Figures 6 & 7).

Loading...

Loading...