INFORMATION FOR REPLACING THE

FUNCTIONAL UNITS

6

63

EN

5. With reference

X

pointed upwards, find the

TDC through tool

ST_30,

then bring the dial

gauge indicator to 0.

6. H

aving identified the value to lower the piston,

rotate the crankshaft anti-clockwise by goin

g

beyond the value described in

Tab. 6.1

, once

ag

ain, rotate the crankshaft clockwise,

stopping at the correct advance value by using

tool

ST_30

7. Lo

ck the

ST_34

t

ool through

J

screws and

ensure that the crankshaft does not rotate,

which would alter the correct advance value. I

f

thi

s happens, repeat the instructions described

in points

4, 5, 6, 7 and 8.

NOTE:

The value indicated in

Tab. 6.1

must be

reached by rotating the shaft with the piston in

compression phase. Use the

ST_34

tool to totate

the crankshaft.

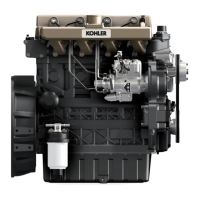

Fig 6.12

8. Lock the

ST_34

tool through

J

screws and

ensure that the crankshaft does not rotate,

which would alter the correct advance value. I

f

thi

s happens, repeat the instructions described

in points

4, 5, 6, 7 and 8

.

9. Undo the screws

AC

and remove the oil filling

flange

AD

.

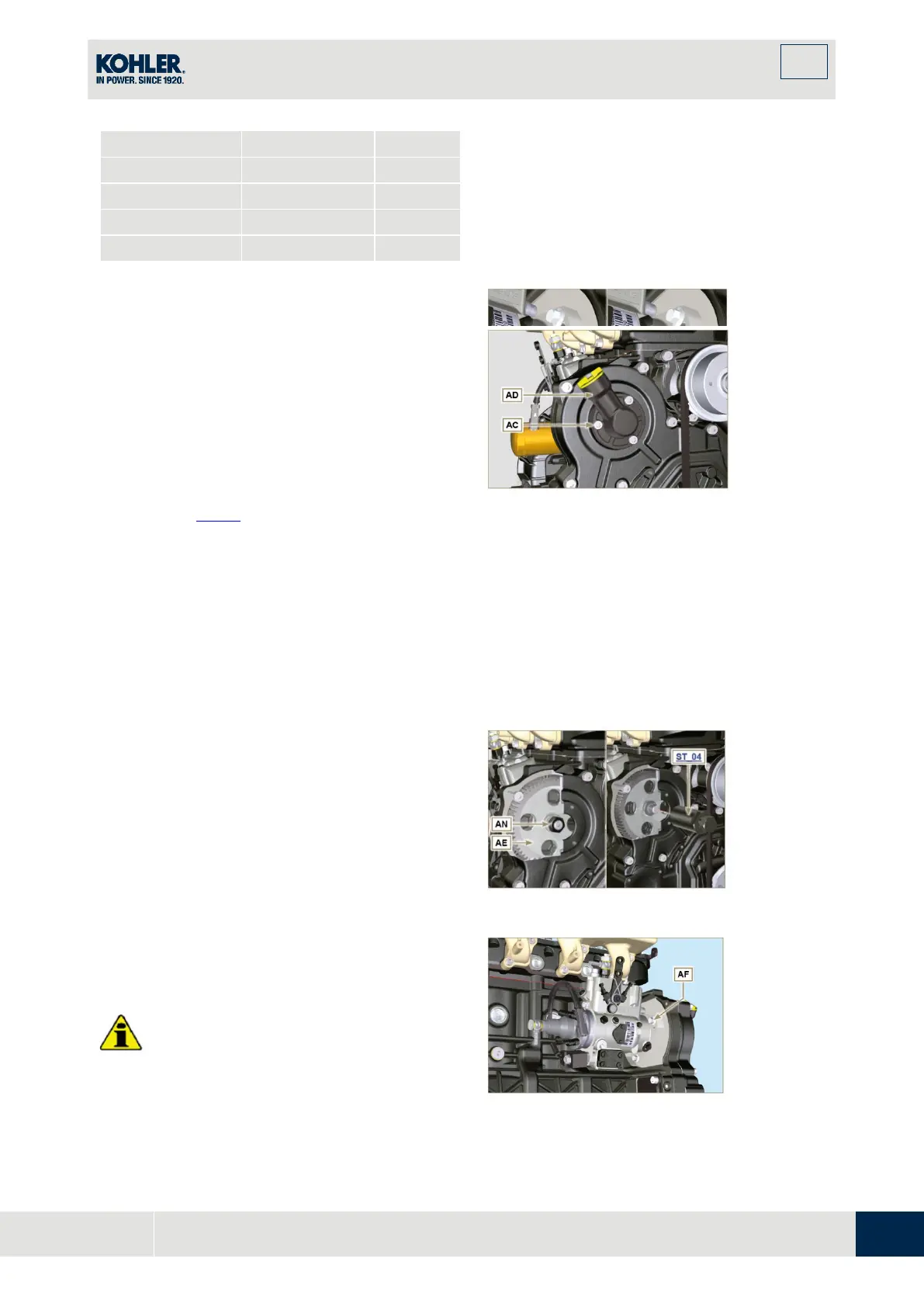

10. Undo and remove the nut

AN

fixing the

injection pump control gear

AE

.

11. U

ndo the capscrew

K

and shift the slotted

plate

AB

in the direction of arrow

AA

.

12. T

ighten screw

K

to block the pump (tightening

torque to

12

Nm

).

Important

•

After removing the nut AN, ensure that the

correct advance value has remained

Fig 6.13

Fig 6.14

Loading...

Loading...