8

INFORMATION ABOUT OVERHAULING

EN 110

M

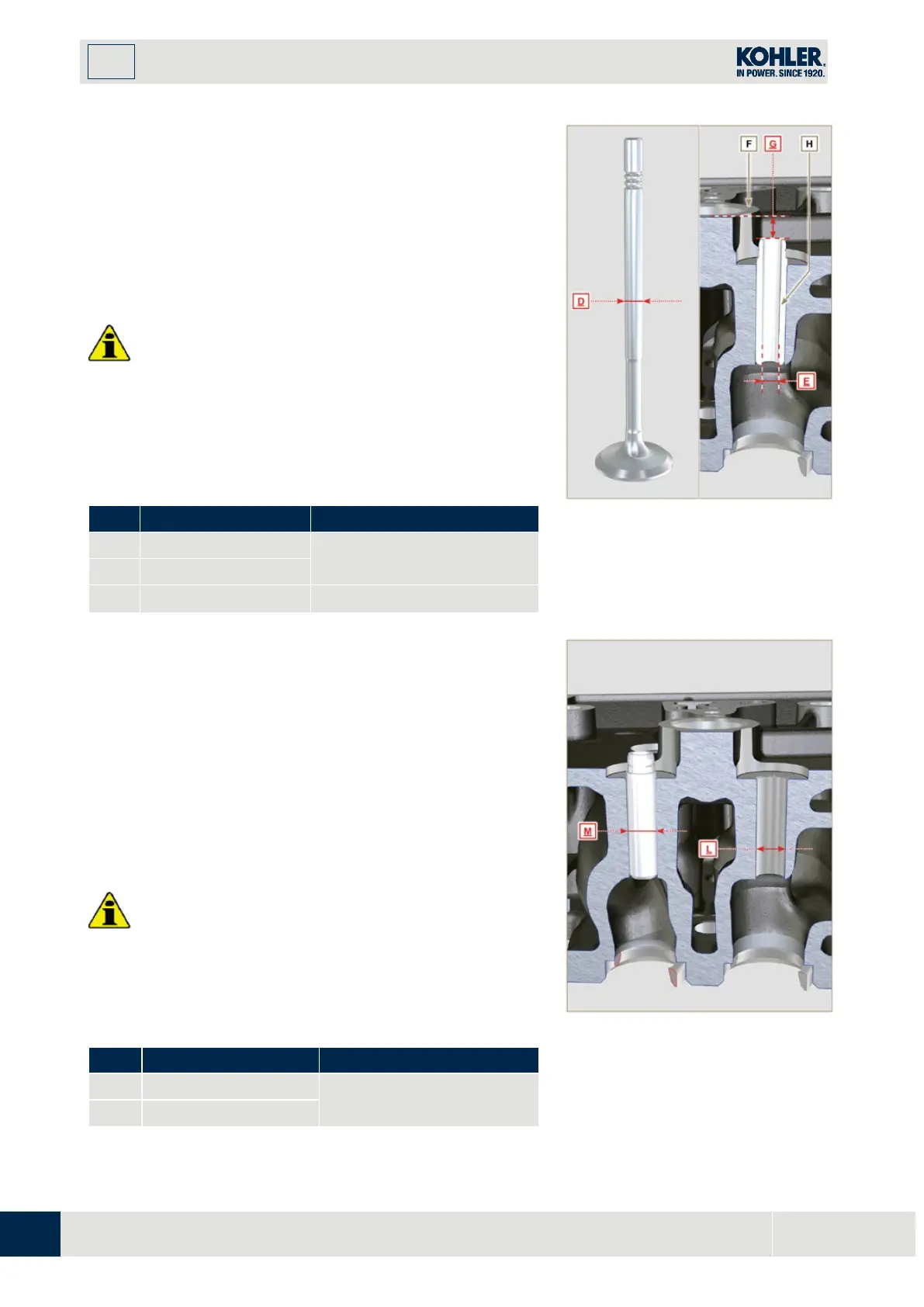

easure the diameters

D

and

E

of the rods and guides valve

(Tab. 8.10)

.

If the diameters don't correspond to the values indicated,

replace the valves or guides.

The

MAX

allowed value of wear for

D and E

is 0.10 mm.

Observe values G from surface F when assembling guides H

(Tab. 8.10).

Important

•

Carry out the measurements in different points to detec

t

an

y ovalisation and/or concentrated wear.

•

Tab. 8.10 details the dimensional values of new

components only.

•

Tab 8.10 Valve stem - valve guide dimensions

0.040 - 0.064

Fig 8.23

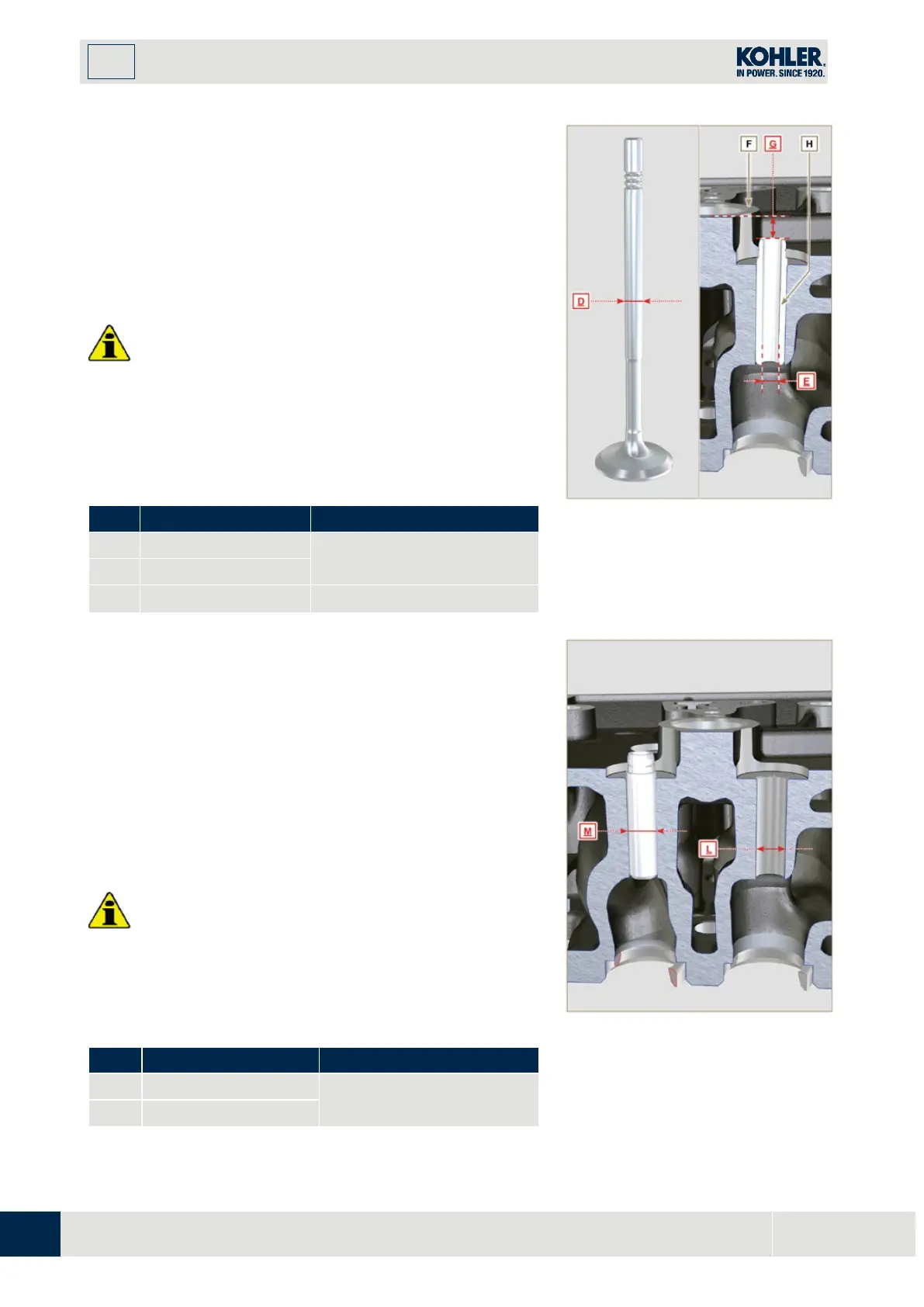

8.6.5 Valve guides replacement

The intake and exhaust guides are both made out of grey iron

with pearlitic phosphoric matrix and they have the same

dimensions.

The guides are press-fit assembled; assembly is possible by

cooling the guides with the aid of liquid nitrogen.

Before assembling a new guide, measure value L and

M,calculate the press-fit value, which must observe the values in

Tab. 8.11.

Observe values G from surface F when assembling guides H

(Tab. 8.10 - Fig. 8.23).

Important

•

The guides must be worked for value E (Tab. 8.10 -

Fig.8.23) after driving. Contact a rectification workshop

for such operations.

Tab 8.11 valve guides - housing dimensions

0.030 - 0.054

Fig 8.24

Loading...

Loading...