INFORMATION ABOUT OVERHAULING

8

111

EN

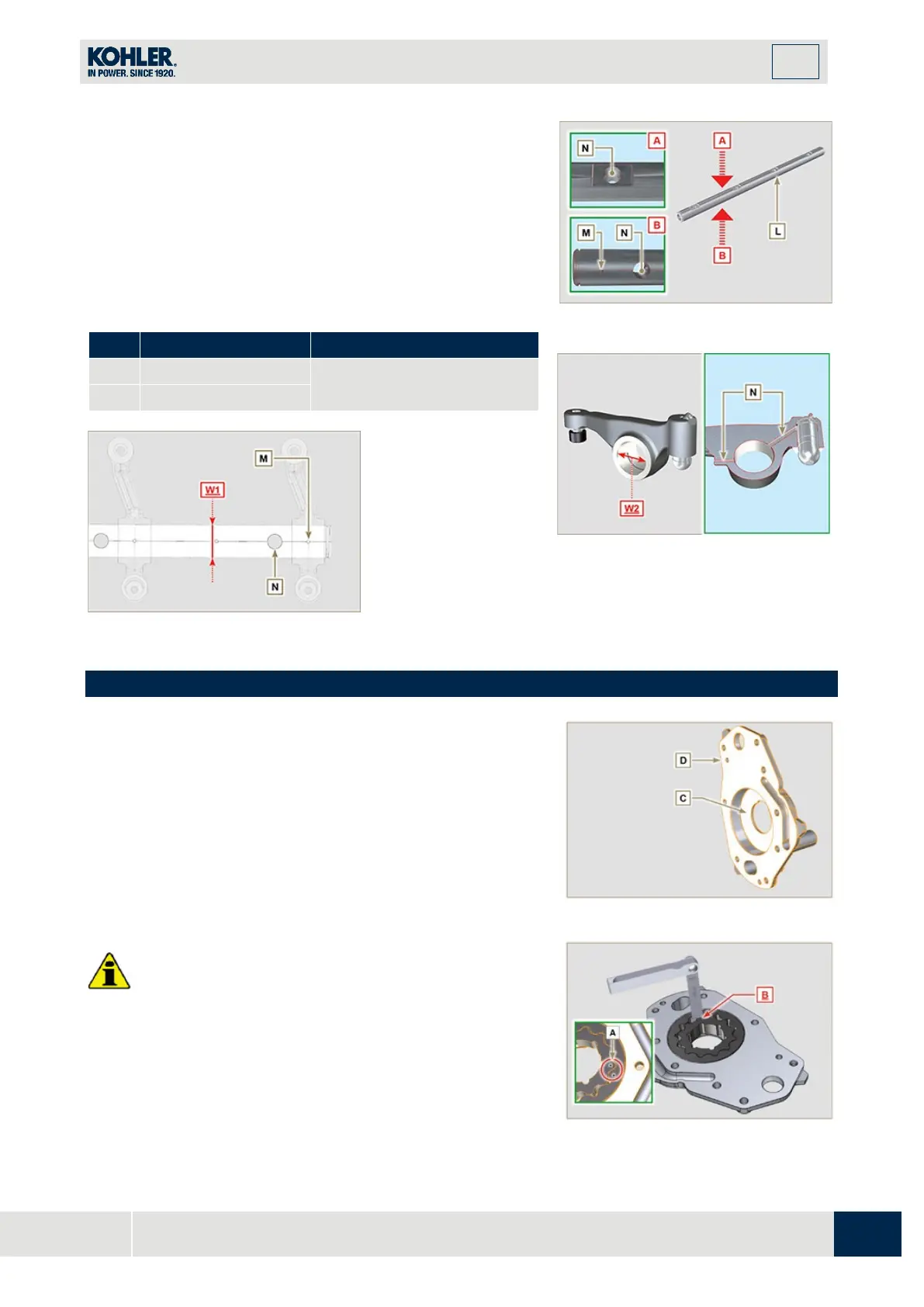

Measure values W1 in correspondence with holes M located on

rocker arm gudgeon L (seen from B in Fig. 8.25).

Measure values W2 (Fig. 8.27).

Based on the values measured, calculate the clearance between

W1 and W2, which is to observe the values in Tab. 8.12.

Check that all oil pipes N and M are free from impurities or

obstructions.

T

ab 8. 12

0.035 - 0.076

Fig. 8.26

Fig 8.25

Fig 8.27

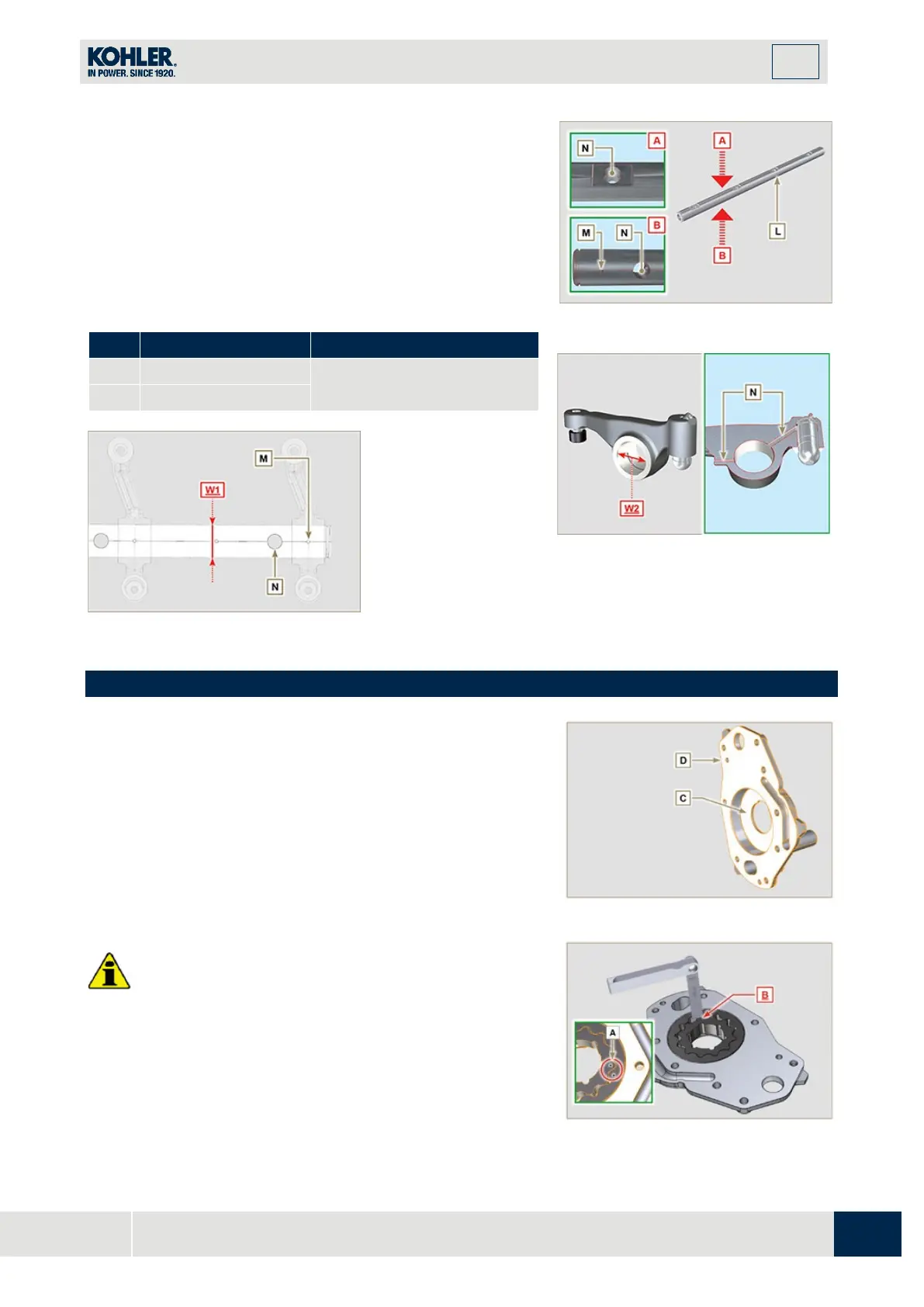

8.7 Oil pump check

8.7.1 Dimensional and visual check

Perform the operations described in

Par.7.8.1 and Par.7.8.4.

Measure clearance value B between the rotor teeth, the value of

allowable wear is MAX 0.28 mm.

Clean all the components thoroughly, check that the work

surfaces C of the rotors and pump body are not worn.

Important

•

Should the results from checks carried out not be i

n

acco

rdance with the conditions described, replace th

e

timing system carter together with the oil pump.

On assembly, references A must be visible.

Fig 8.28

Loading...

Loading...