6

INFORMATION FOR REPLACING THE

FUNCTIONAL UNITS

EN 70

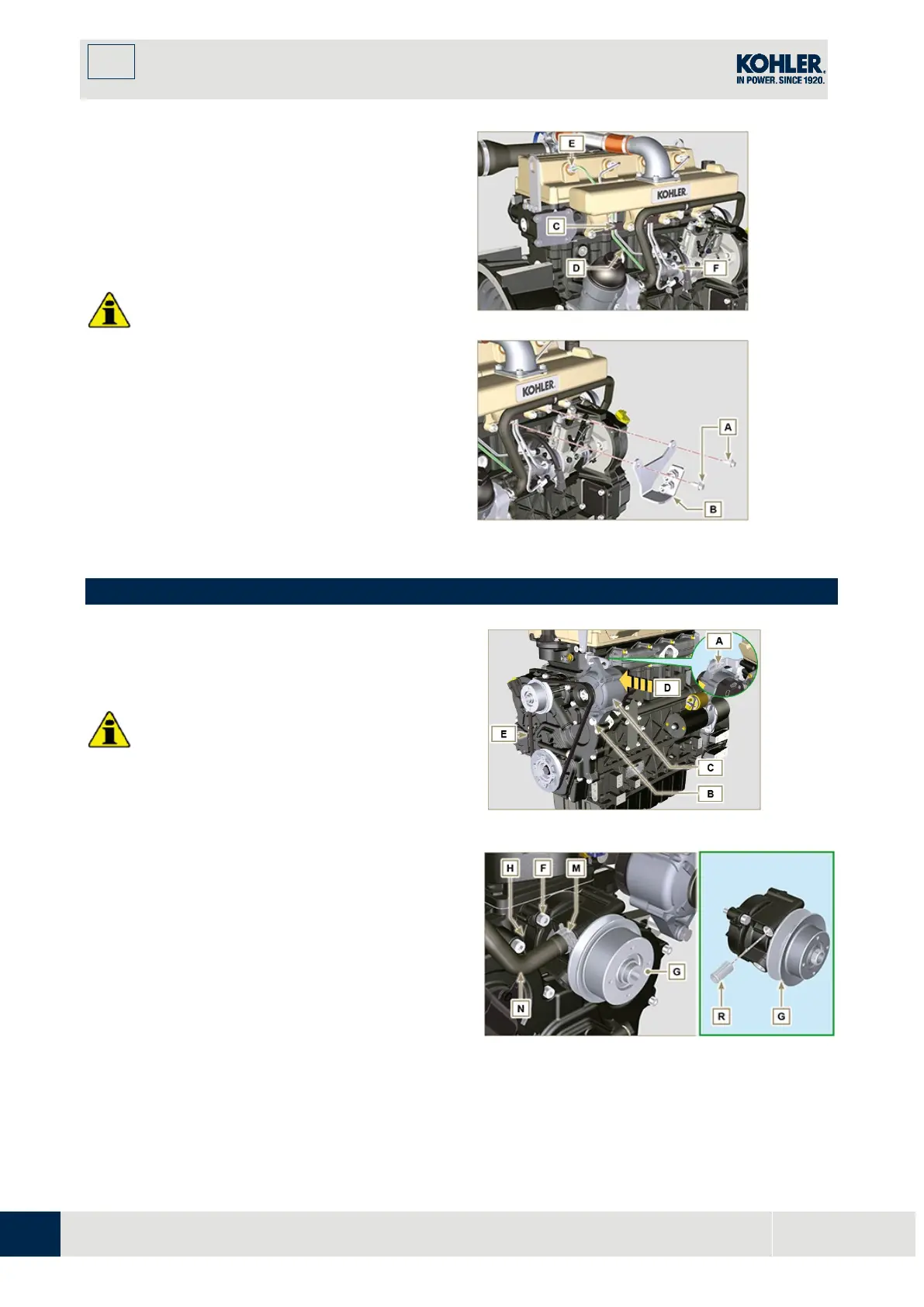

6.1.10 Installation of the fuel injector pipes

(pump injector/injectors)

1.

Position pipes D on the injectors and on the

injector pump.

I

mportant

•

Tighten the nuts E and F manually, witho

ut

clamping them.

2. Tighten the nuts

E

ed

F

(tightening torque at

25

Nm

)

.

3. Reinstall the retainers

C

of the hoses

D

.

4. Fix the plate

B

by using screws

A

(tightening

torque to

10 Nm

).

Fig 6.29

Fig 6.30

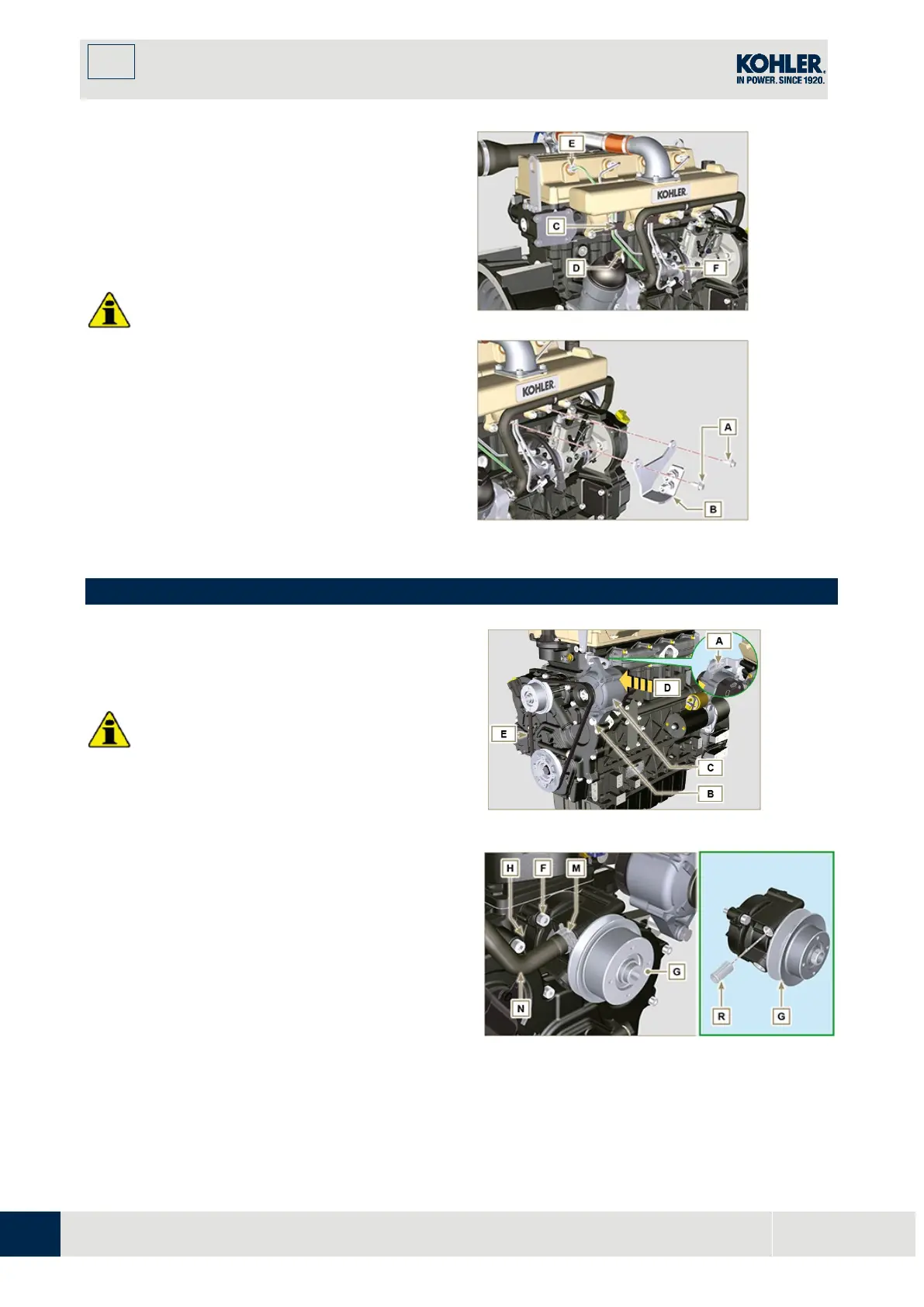

6.2 Coolant pump replacement

1.

Perform the operations described in Par. 5.1.

I

mportant

•

Before proceeding with operation, read Par.

3.3.2.

•

The pump G isn't repairable.

•

If the engine is fitted with the Poly-V belt,

perform the operations described in Par.

11.9.

2. Loosen the screws

A and B.

3. Push the alternator

C

in the direction of the arrow

D

and remove the belt

E

.

4. Re

move the clamp

M

and disconnect the pipe

N

from the pump

G

.

5. Loosen the screws

F

and remove the pump

G

and

relative gasket

H

.

NOTE

: If union

R

, is disassembled, replace it or

alternatively apply

Loctite 2701

on the thread when

assembling on pump

G

(tightening torque of

20 Nm

).

Fig 6.31

Fig 6.32

Loading...

Loading...