INFORMATION FOR REPLACING THE

FUNCTIONAL UNITS

6

71

EN

Important

•

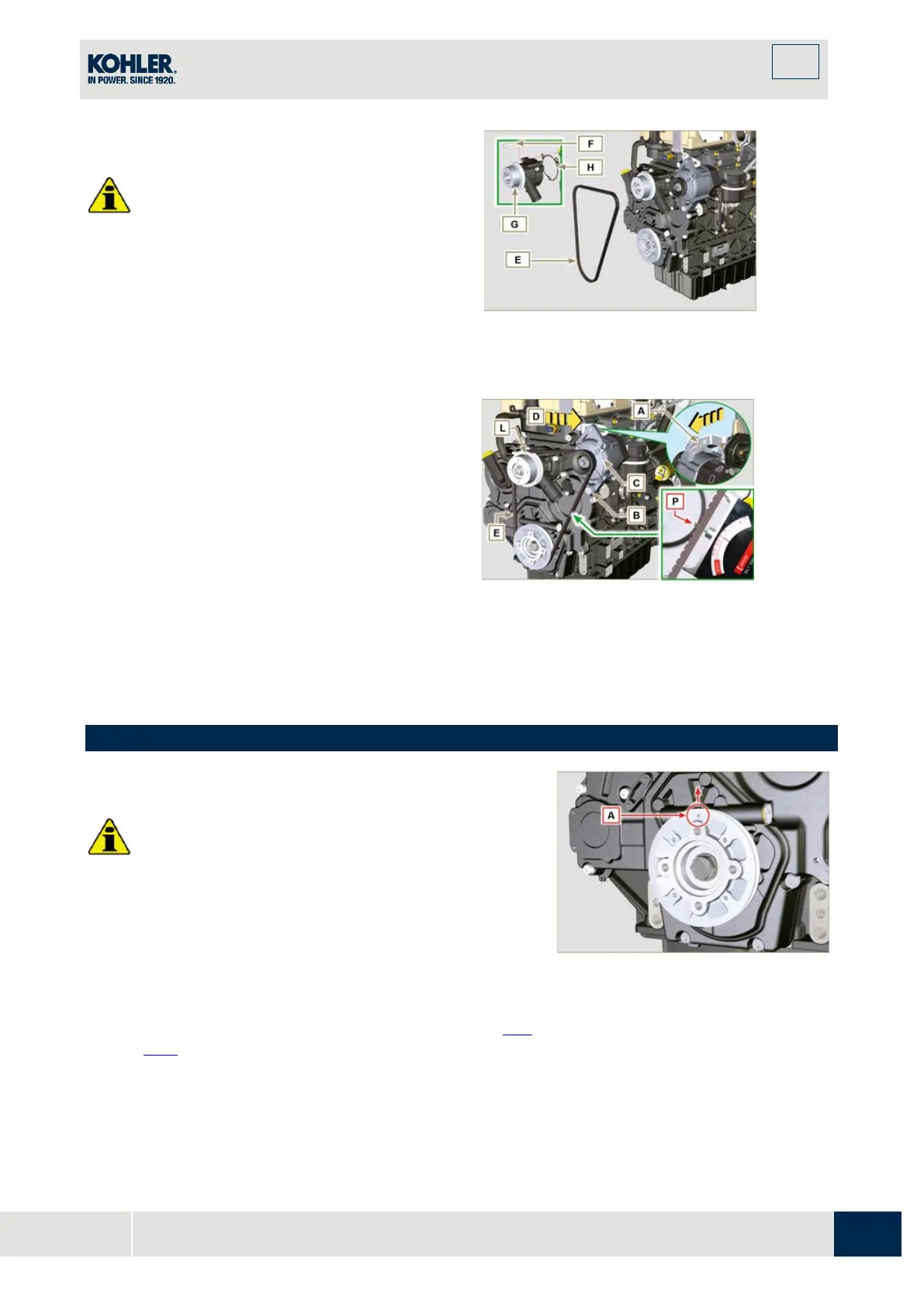

Always replace the gaskets H, after each

disassembly.

•

Always replace the belt E after each

assembly.

1.

Fit the coolant pump G with the screws F

interposing the new gasket H (tightening

torque at 25 Nm).

Fig 6.33

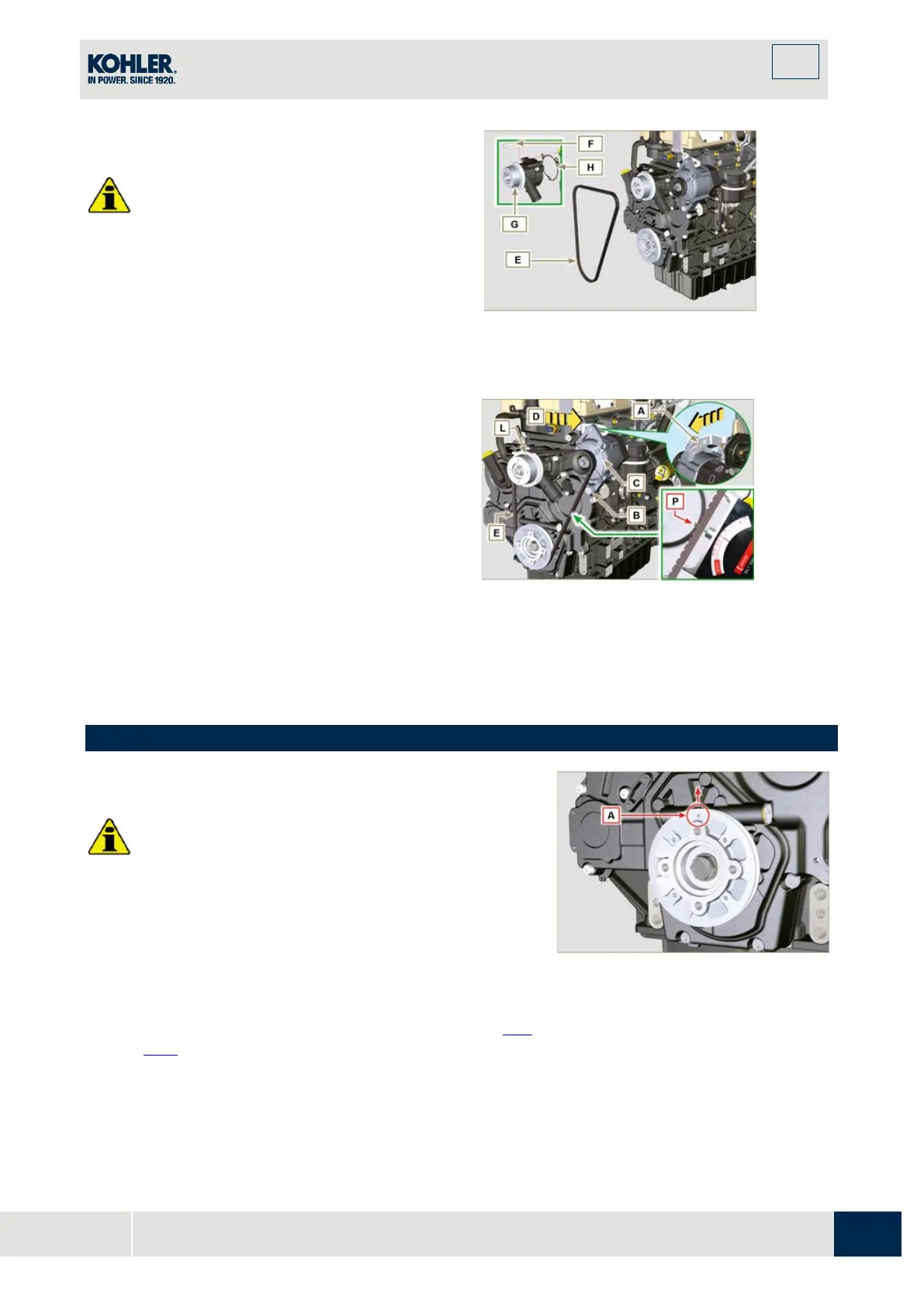

Insert the belt E on the pulleys L.

3.

Push the alternator C in the direction of the

arrow D.

4.

While tensioning the alternator C, first clamp

screw A (tightening torque at 25 Nm) an

d

the

n screw B (tightening torque at 69 N

m

[t

hread M10] - 40 Nm [thread M8]).

5.

Check the tension of the belt E with the

instrument (DENSO BTG-2), positioning it in

point p (the tension must be between 20

0

a

nd 230 N)

6.

If the tension values do not correspond,

tighten screws A and B, then repeat

operations 3, 4 and 5.

Fig 6.34

6.3 Replace the crankshaft pulley

Important

•

Before proceeding with operation, read Par. 3.3.2.

NOTE:

Perform the operations described in

Par. 6.1.5 steps 2

and 3

.

1.

Position the crankshaft with the 1st cylinder in TDC,

reference A.

2.

Remove the alternator belt following steps 2 and 3 (Par.

6.2.1).

Fig 6.35

Loading...

Loading...