6

INFORMATION FOR REPLACING THE

FUNCTIONAL UNITS

EN 72

3.

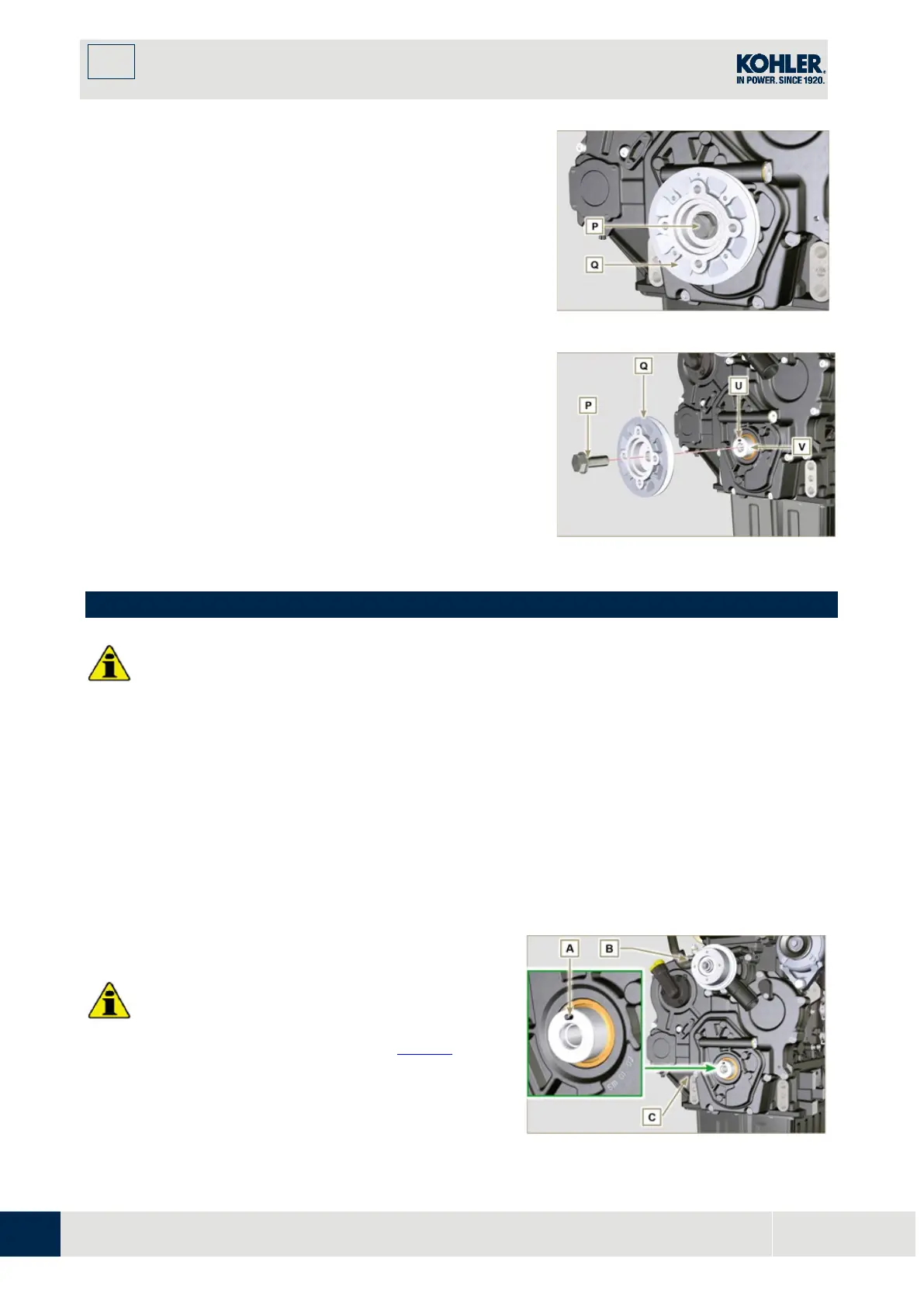

Undo the screw P (clockwise) and remove the pulley Q.

6.3.2 Assembly

1.

Check that the pin U is mounted properly on the

camshaft V.

2.

Insert the pulley Q on camshaft V respecting the

r

eference of the pin U.

3.

Apply Molyslip grease on the screw thread P.

4.

Fit the pulley Q with the screw P (tightening torque 360

Nm) and remove the tool ST_34.

6.4 Oil pump replacement

•

Before proceeding with operations, read Par. 3.3.2.

•

The oil pump is not repairable.

6.4.1 Coolant pump disassembly

1.

Perform the operations described in Par 6.2.1.

6.4.2 Engine pulley disassembly

1.

Perform the operations described in Par 6.3.1.

6.4.3 Timing system crankcase disassembly

Important

•

Perform the operations described in Par. 5.2.

1.

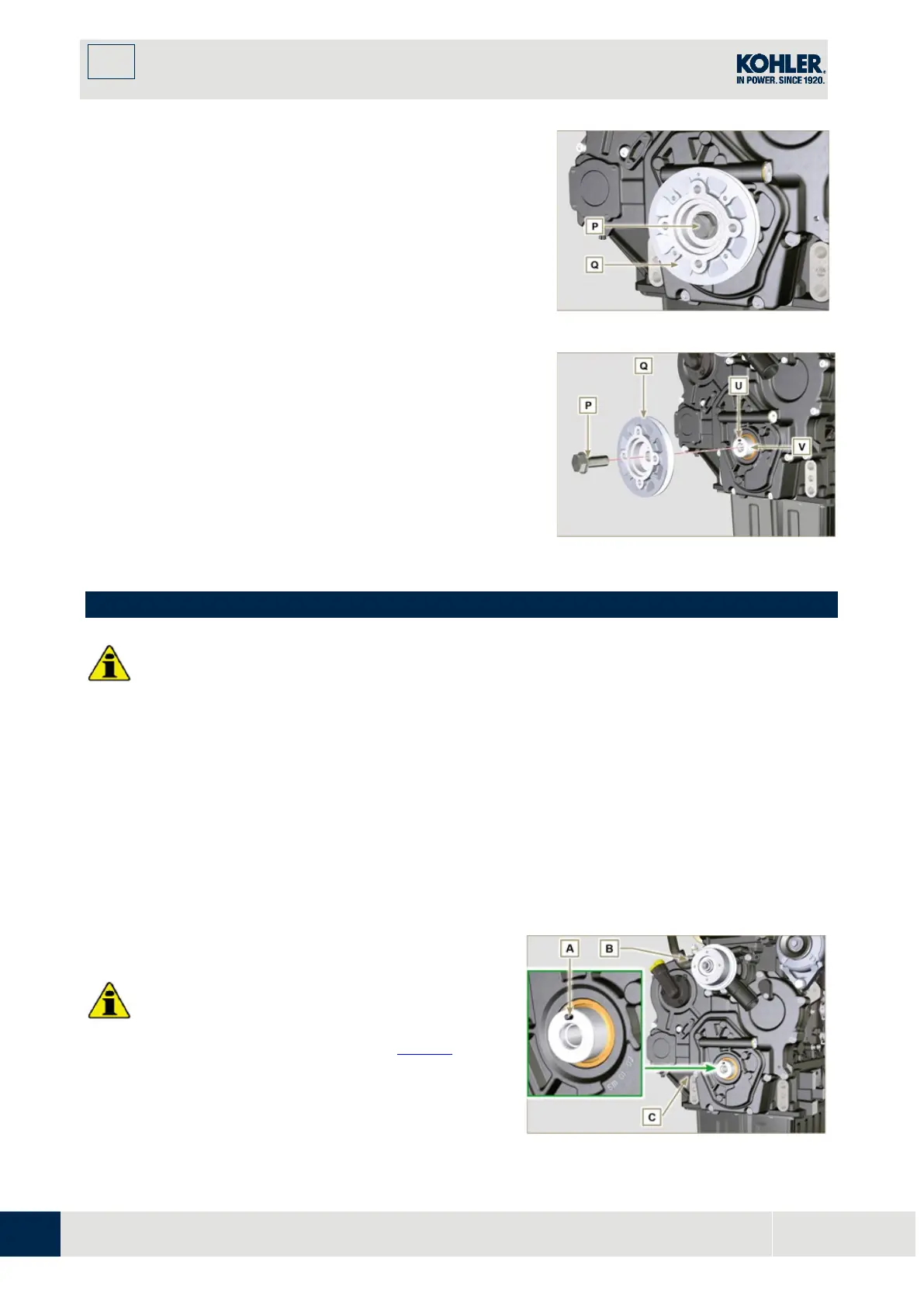

Make sure that the reference pin A is facing

upwards.

2.

Undo the screws B and remove the timing system

crankcase C.

Fig 6.38

Loading...

Loading...