INFORMATION ABOUT OPTIONAL

COMPONENTS

11

165

EN

2.

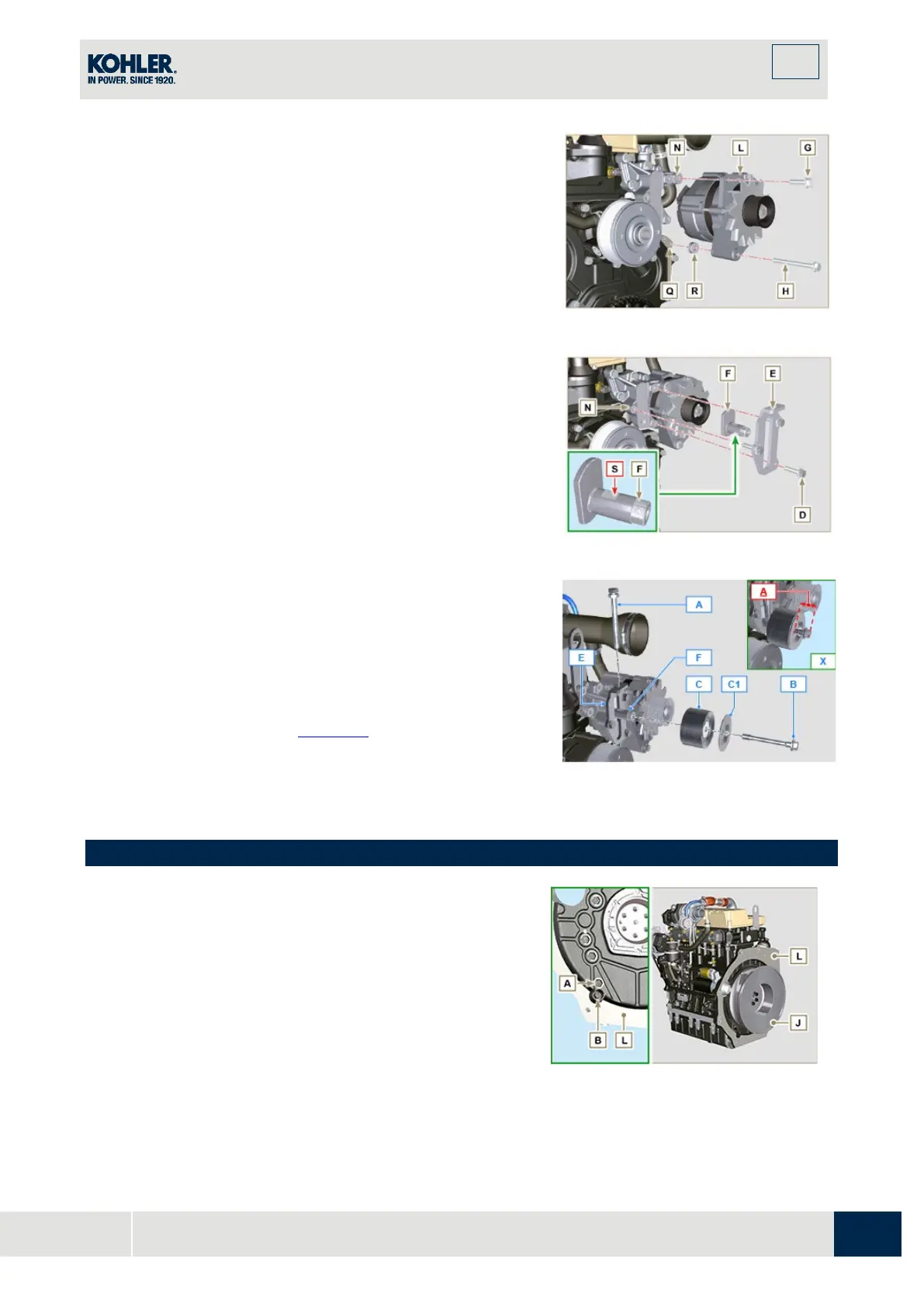

Insert the screw H into the fixing hole on the alternator L.

3.

Insert the spacer R on the screw H (between the

alternator and crankcase).

4.

Tighten the screw manually H onto the crankcase Q.

5.

Orientate the second fixing hole of the alternator L wit

h

t

he hole of the bracket N, secure the alternator L using

the screw G (tightening torque at 25 Nm) onto the

bracket N and then the screw H (tightening torque at

25

Nm)

.

6.

Insert the pin F in the plate slot E.

7.

Orientate the pin F with the surface S (support for screw

A) upwards.

8.

Secure the plate E using the screws D on the bracket N

(tightening torque at 25 Nm).

Insert the screw

in the plate

and pulley

.

10.

Manually tighten the screw B onto the pin F up to the

stop; Undo the screw B again by one turn.

NOTE: The screw B must protrude by about 32 mm (A) from the

surface of the tightening pulley C (see detail X).

11.

Install the new belt H (Fig. 11.43).

12.

Tighten the screw A onto the plate E up to the stop o

n

the

pin F.

13.

Perform the operations point 6 to 8 of Par. 11.9.

Fig 11.52

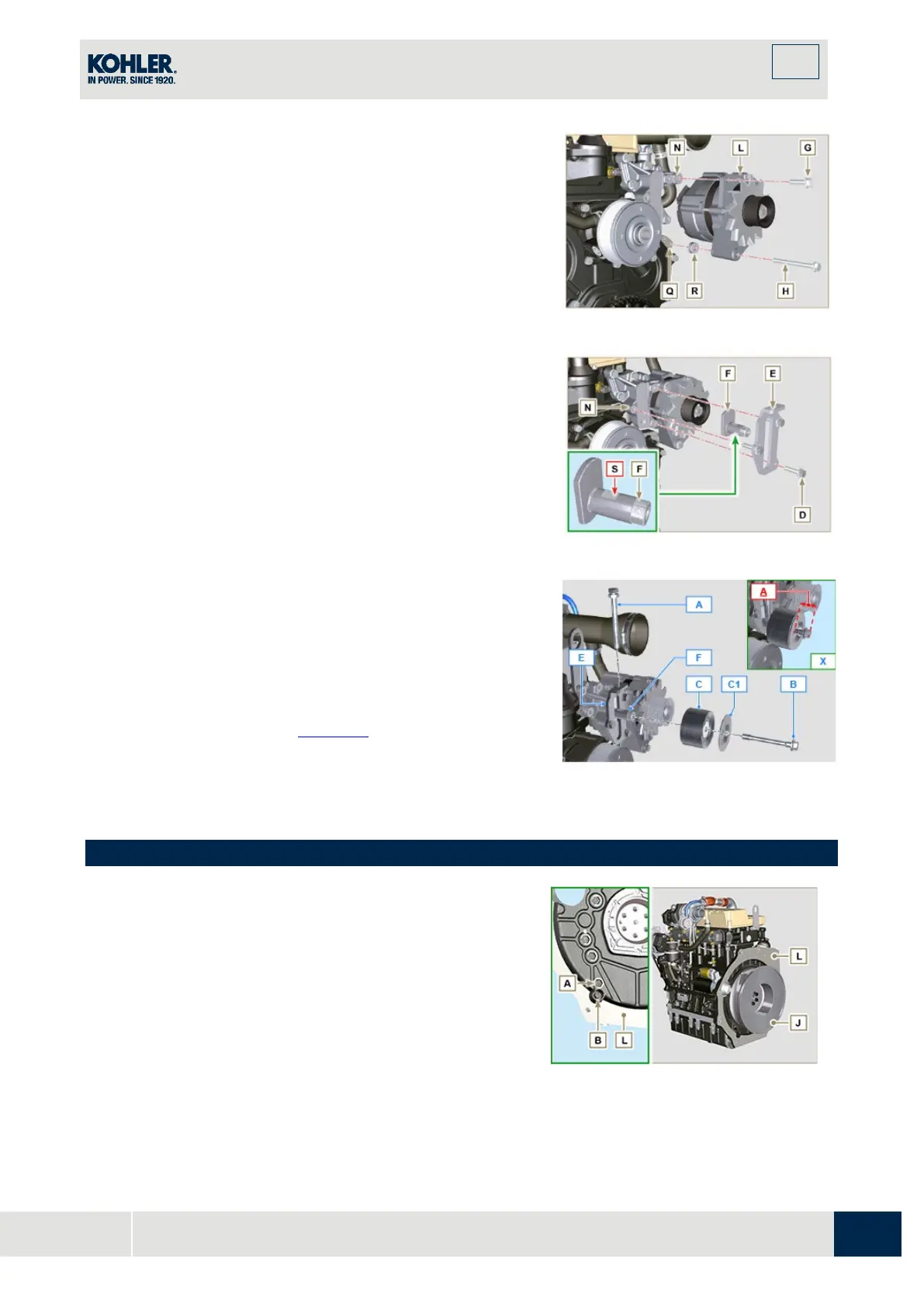

11.11 Oil sump with supporting structure

11.11.1 Flywheel (J) disassembly

1.

Execute the operations described in Par. 7.11.1.

11.11.2 Plate/flange housing (L) disassembly

1.

Loosen supplementary capscrews A and B.

2.

Execute the operations described in Par. 7.11.2.

3.

Remove housing or plate L.

Fig. 11.53

Loading...

Loading...