11

INFORMATION ABOUT OPTIONAL

COMPONENTS

EN 166

11.11.3 Oil sump disassembly

1.

Execute the operations described in Par. 5.2.

2.

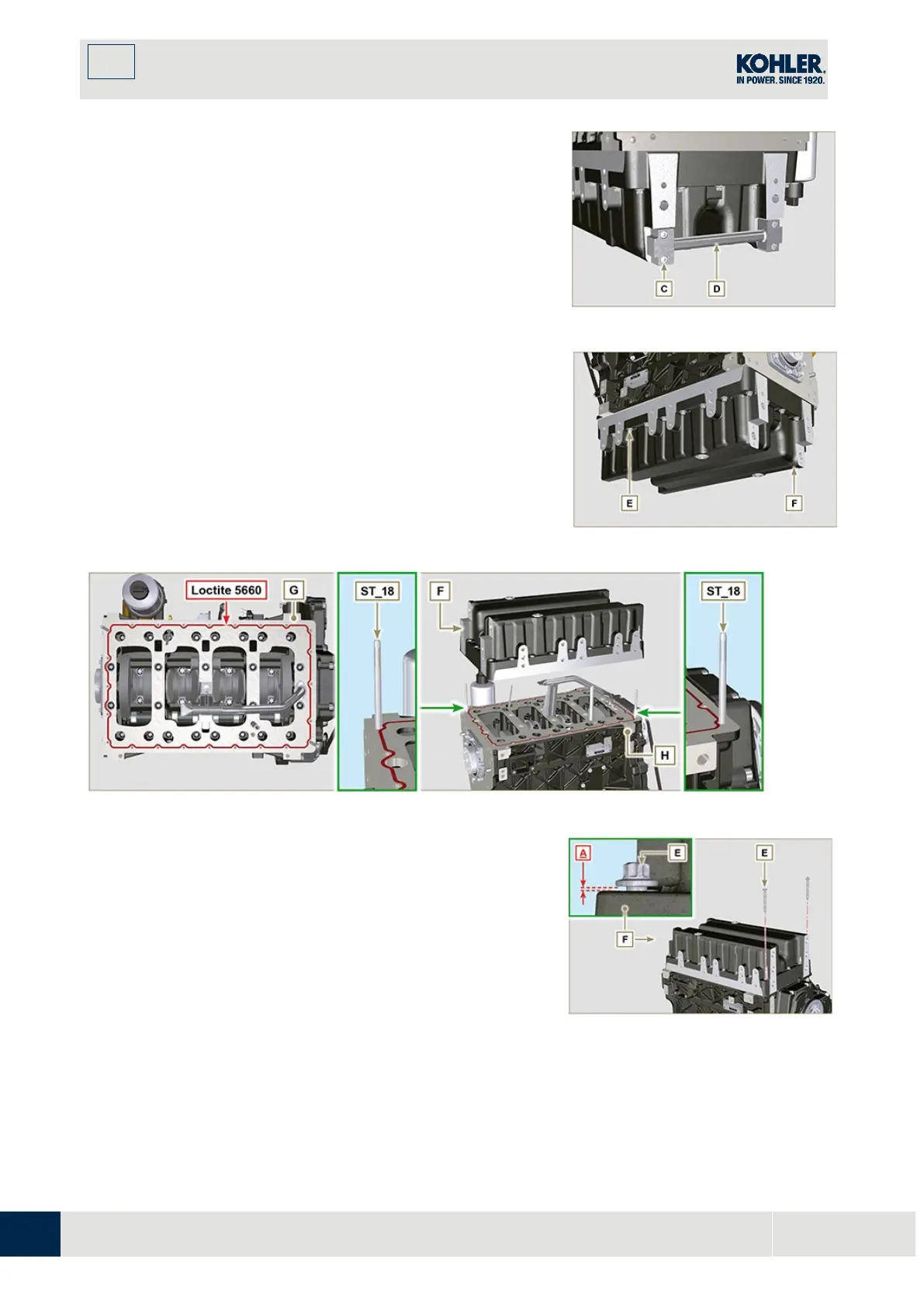

Loosen capscrews C and remove bypass tube D.

3.

Loosen capscrews E and remove oil sump F.

Fig. 11.54

11.11.4 Oil sump assembly

1.

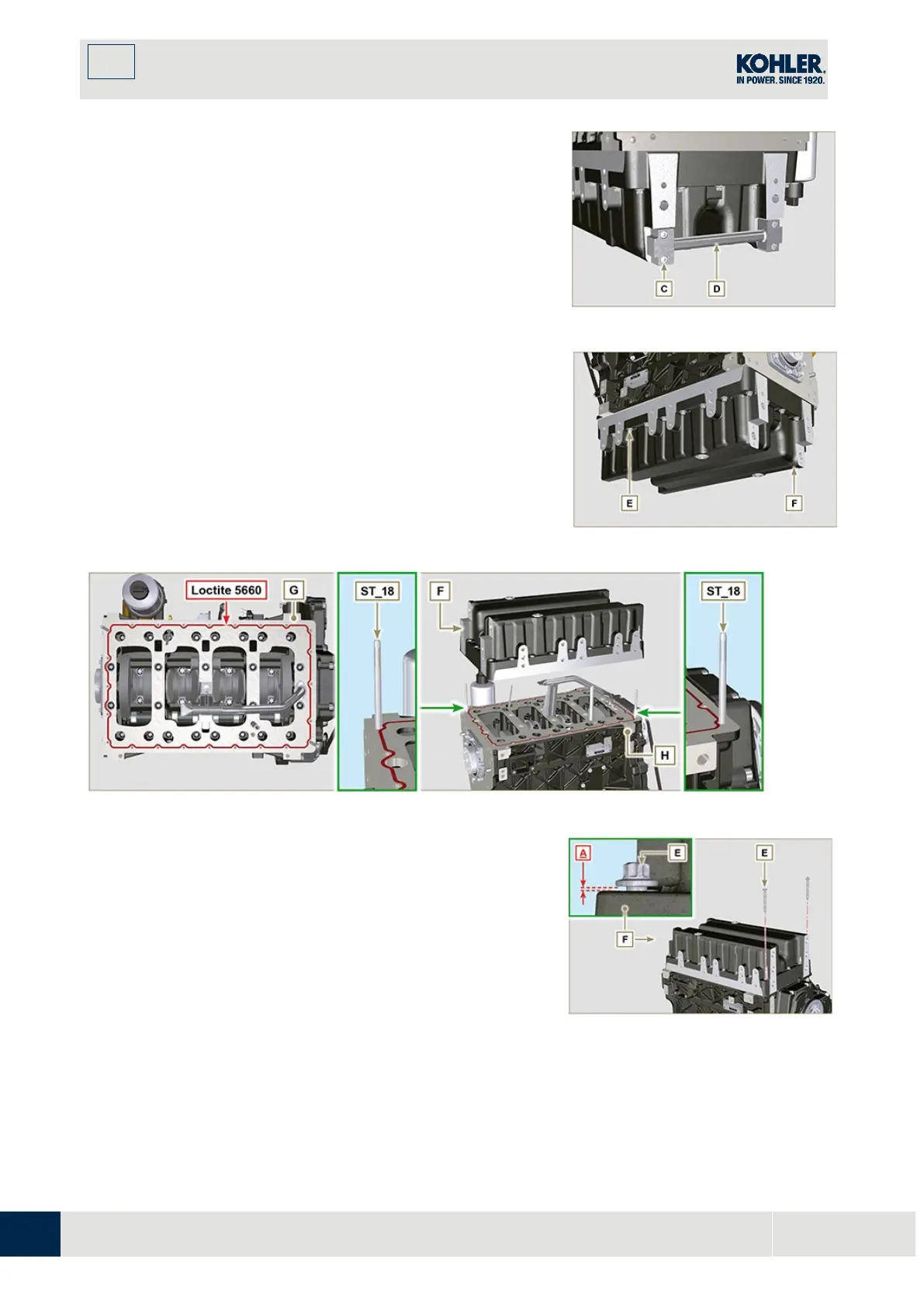

Make sure contact surfaces G of oil sump F an

d

cr

ankcase H have no impurities.

2.

Apply a sealing bead of approximately 2.5 mm (Loctit

e

5660) onto surface G of crankcase H.

3.

Place oil sump F onto crankcase H in correspondence

with the fastening holes (use tool ST_18).

Fig. 11.55

Fig. 11.56

Apply capscrews E into the fastening holes and use

torque at 10 Nm.

5.

Loosen capscrews E, leaving approximately 1 mm leeway

(position A) between the neck surface of capscrews E

and oil sump F.

6.

Place flange housing or plate L onto crankcase H,

complying with centring tap pins M.

7.

Using 2 capscrews A, fasten housing or plate L onto

crankcase H (tightening torque at 20 Nm).

8.

Using 2 capscrews A, fasten housing or plate L onto oil

sump F (tightening torque at 20 Nm).

Fig. 11.57

Loading...

Loading...