3-13

bizhub PRESS C71cf

3

)Adjust the tension according to the type of media being used.

The tension can be adjusted with the combination of following settings.

- Tension roller 2

- Aligning roller

- Tension roller 4

- Paper feed loop fan

For details on the setting guides for tension, refer to the following table and figures.

<High Speed>, <Mid Speed>, <Low Speed> found in the table indicate print speed.

Configure the one rank higher tension than the tension in the table when the paper width is 250 mm. (Example :

R5 -> R6 )

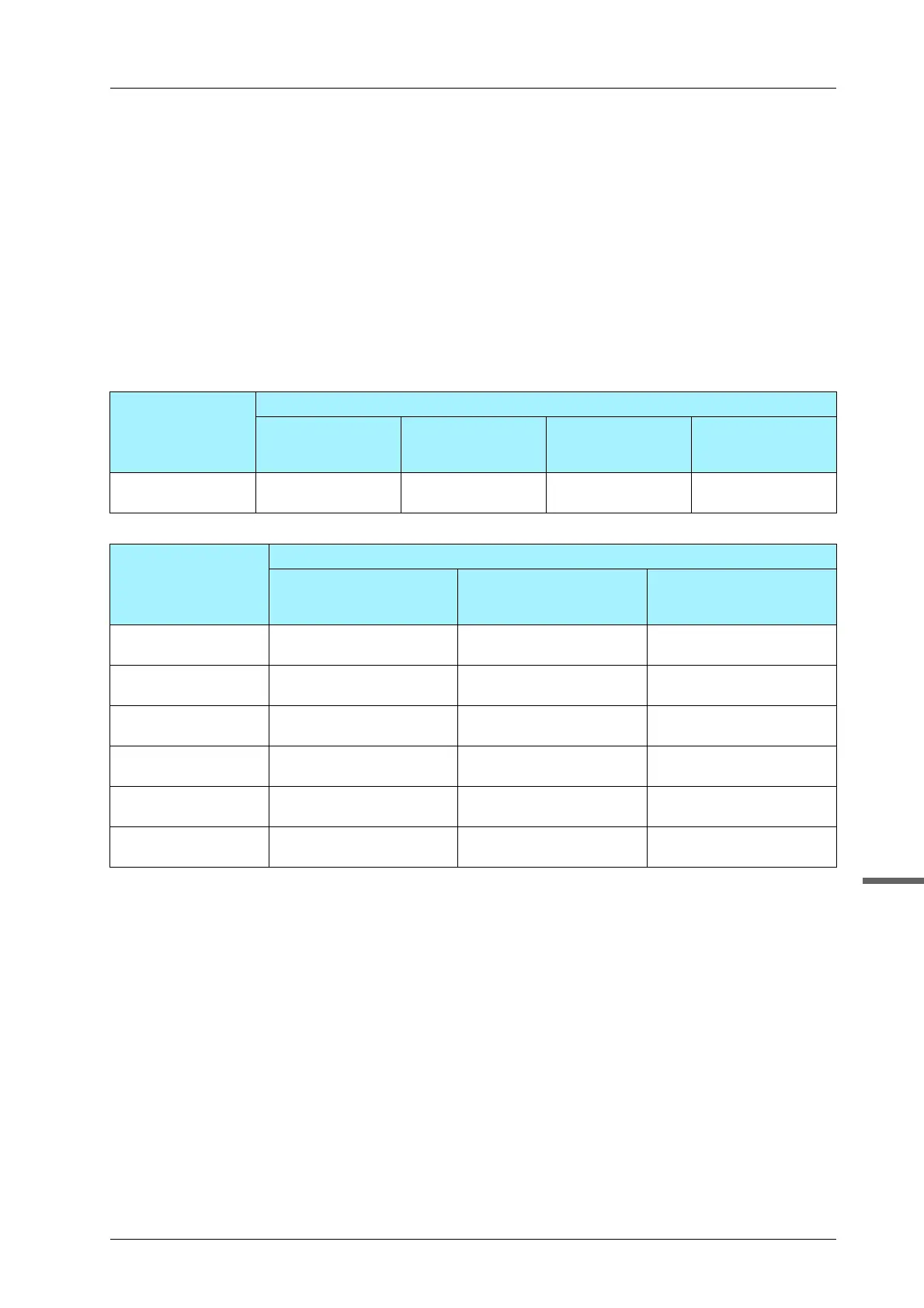

<Paper setting guide table>

Paper Type Thickness (weight)

90-110 μm

(81-91 g/m

2

/

22-24 lb Bond)

111-130 μm

(92-105 g/m

2

/

25-28 lb Bond)

131-160 μm

(106-135 g/m

2

/

29-36 lb Bond)

161-210 μm

(136-176 g/m

2

/

37-47 lb Bond)

Non-tack

Plain

<High Speed>

R5

<High Speed>

R5

<High Speed>

R3

<Mid Speed>

R1

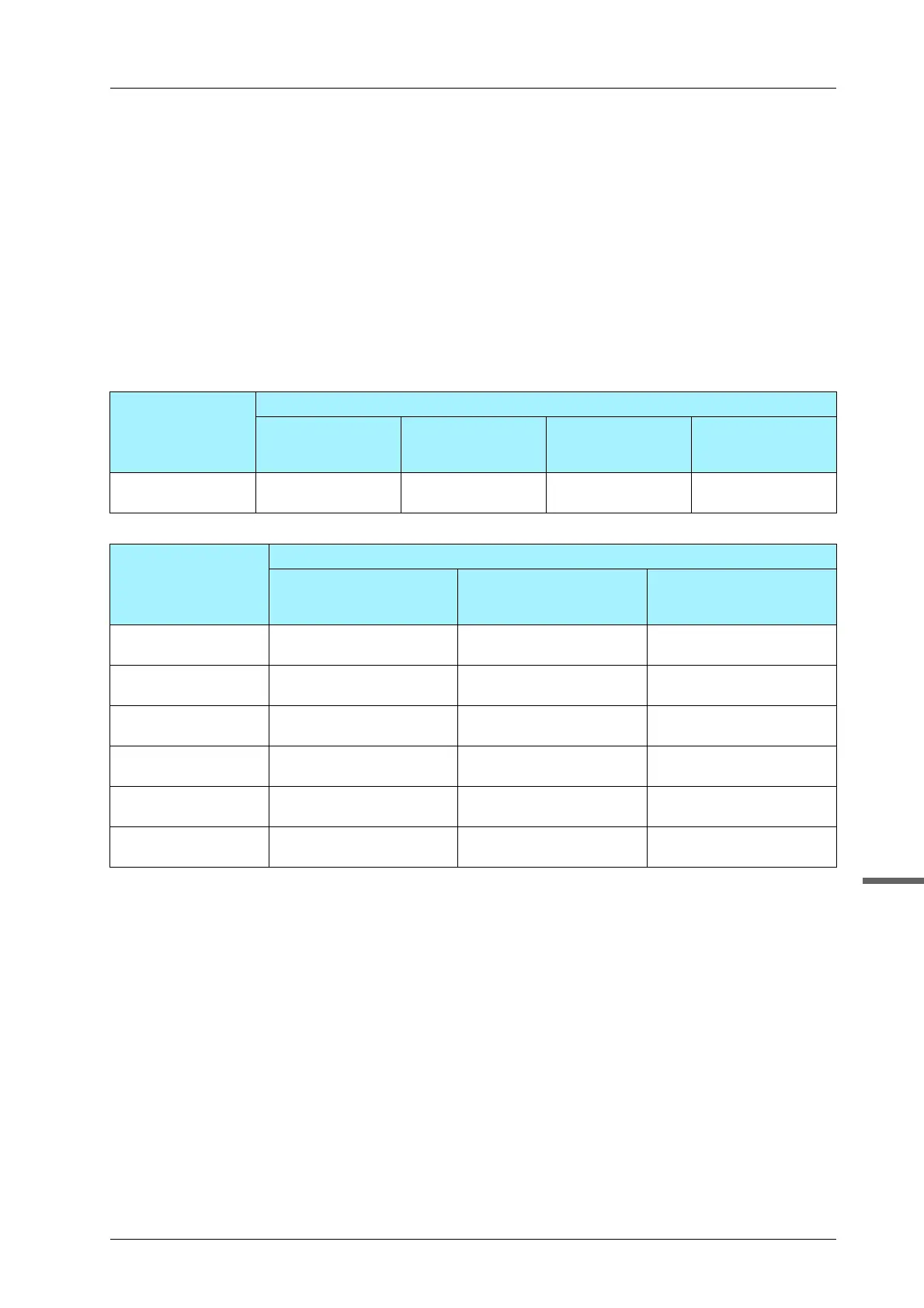

Paper Type Thickness (weight)

120-160 μm

(136-176 g/m

2

/ 37-47 lb

Bond)

161-195 μm

(177-216 g/m

2

/ 48-57 lb

Bond)

196-250 μm

(217-256 g/m

2

/ 58-68 lb

Bond)

Tack

Plain

<Mid Speed>

R3

<Low speed>

R3

<Low speed>

R1

Tack

Coated-G

<Mid Speed>

R3

<Low speed>

R3

<Low speed>

R1

Tack

Coated-M

<Mid Speed>

R4

<Low speed>

R1

<Low speed>

R1

Tack PP

(Synthetic Paper)

<Low speed>

R6

--

Tack PP Film <Low speed>

R4

--

Tack PET Film <Low speed>

R4

<Low speed>

R4

-

Loading...

Loading...